Super glue does not stick to nonstick surfaces and certain plastics. Super glue, also known as cyanoacrylate adhesive, is a popular adhesive used for a variety of purposes, from fixing broken items to crafting.

However, it does not work on all surfaces. Knowing what surfaces super glue won’t stick to can save you time and frustration. In this blog post, we will discuss the surfaces that super glue won’t adhere to and why.

Additionally, we will provide tips on how to prepare surfaces for super glue application to ensure a strong bond. So, keep reading to learn more about the limitations of super glue.

Contents

Introduction To Super Glue

Super glue, also known as cyanoacrylate adhesive, is a powerful bonding agent that has become a staple in households and industries. Its ability to create strong and long-lasting bonds makes it a go-to solution for a wide range of repair and construction projects.

But have you ever wondered what super glue does not stick to? In this blog post, we will explore the fascinating world of super glue and its limitations, uncovering the materials and surfaces that are resistant to its adhesive properties.

A Brief History

Super glue was first discovered in 1942 by Dr. Harry Coover, a chemist working for Eastman Kodak. Initially, it was deemed too sticky for practical use, but its potential was later recognized, leading to its commercialization in the 1950s.

Since then, super glue has evolved to offer various formulations catering to specific bonding needs, cementing its status as a versatile and indispensable adhesive.

The Science Behind The Stick

The secret to super glue’s remarkable bonding strength lies in its chemical composition and reaction with moisture. When exposed to water vapor in the air or on a surface, the cyanoacrylate molecules undergo a rapid polymerization process, forming strong chains that bind the materials together.

This instantaneous bonding mechanism is what sets super glue apart from traditional adhesives, making it a preferred choice for quick fixes and durable connections.

The Mighty Bond Of Super Glue

Super glue, also known as cyanoacrylate adhesive, is renowned for its remarkable bonding capabilities. Despite its impressive strength, there are certain materials that super glue cannot effectively adhere to.

Understanding what super glue does not stick to can help you make informed decisions when using this powerful adhesive.

How Super Glue Works?

Super glue works by creating a strong bond through a process called polymerization. When exposed to moisture, the cyanoacrylate molecules react to form long chains, resulting in a durable and resilient bond. This rapid bonding process makes super glue an ideal choice for various applications.

Common Uses In Daily Life

Super glue finds extensive use in everyday situations, such as repairing broken ceramics, fixing jewelry, and securing small household items. Its ability to create quick and sturdy bonds makes it a popular choice for DIY enthusiasts and professionals alike.

Surfaces That Defy Super Glue

Super glue, also known as cyanoacrylate adhesive, is renowned for its exceptional bonding strength. However, there are certain surfaces that have the uncanny ability to resist its adhesive properties.

If you’ve ever tried to use super glue on non-stick cookware, silicone or rubber, or wet surfaces, you may have noticed that it simply doesn’t stick as intended. In this blog post, we’ll explore why these surfaces defy super glue and provide insights into alternative adhesive options.

Non-stick Cookware

Non-stick cookware, such as Teflon-coated pans, is designed to prevent food from sticking during cooking. This same non-stick property makes it challenging for super glue to adhere to the surface. The slick surface of non-stick cookware repels the glue, preventing it from forming a strong bond.

So, if you accidentally drop a dish and it breaks, reaching for super glue might not be the most effective solution. Instead, consider using a specialized adhesive designed for bonding non-stick materials or consult a professional for repair options.

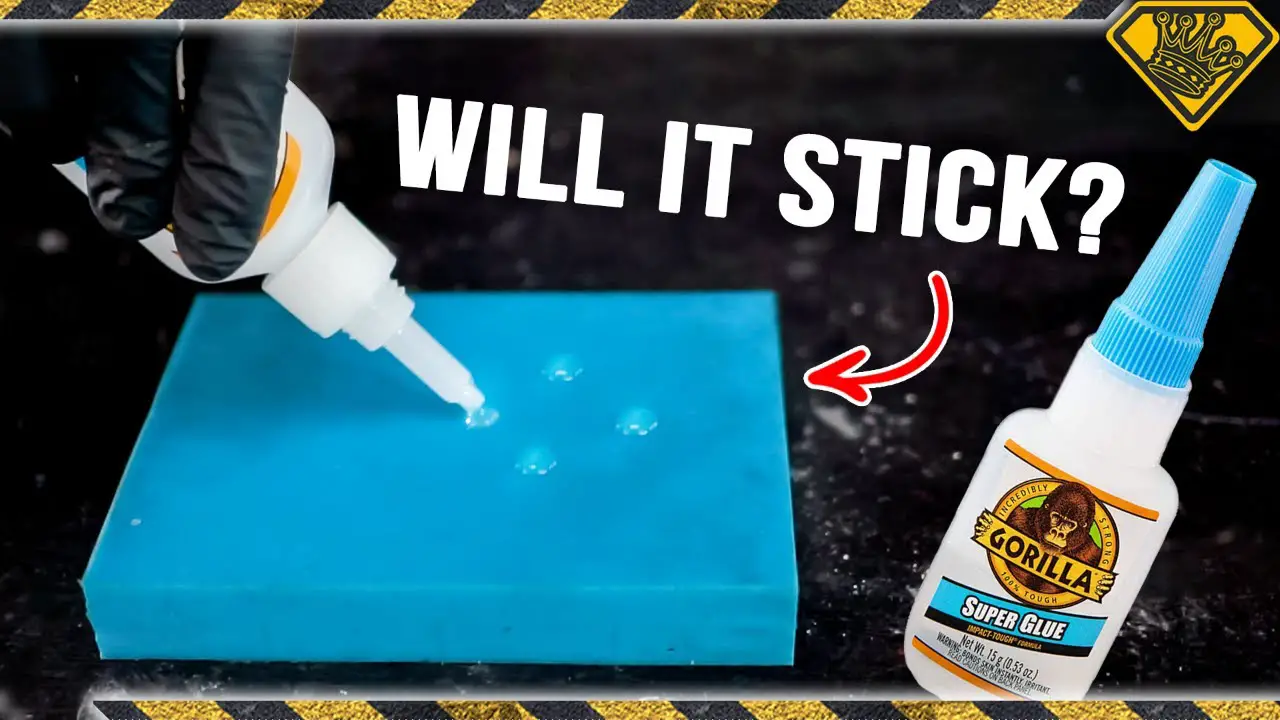

Silicone And Rubber

Silicone and rubber materials are widely used in various applications due to their flexibility, durability, and resistance to extreme temperatures. However, these same properties make them resistant to super glue.

The smooth and low-energy surface of silicone and rubber repels the adhesive, preventing it from creating a secure bond. When it comes to repairing silicone or rubber items, it’s best to use adhesives specifically formulated for these materials. These adhesives are designed to provide strong and long-lasting bonds on silicone and rubber surfaces.

Wet Surfaces

Attempting to use super glue on wet surfaces can be a futile endeavor. The presence of moisture interferes with the curing process of the adhesive, preventing it from fully bonding. Water acts as a barrier, inhibiting the adhesive from making a secure connection between the two surfaces.

If you find yourself needing to bond wet surfaces, it’s advisable to dry them thoroughly first. Once the surfaces are dry, you can explore alternative adhesives that are specifically formulated to work in wet or humid conditions.

The Challenge With Plastics

When it comes to super glue, one of the common challenges is finding a plastic material that it can effectively bond to. Plastics like polyethylene and polypropylene pose a unique challenge due to their low surface energy.

Polyethylene

Polyethylene is a widely used plastic in various applications due to its low cost and versatility. Super glue struggles to bond with polyethylene because of its non-porous nature and smooth surface.

Polypropylene

Similar to polyethylene, polypropylene is another plastic that resists bonding with super glue. Its slick surface and low surface energy make it difficult for the adhesive to form a strong bond.

Some plastics like polyethylene and polypropylene have a molecular structure that repels the bonding properties of super glue. The smooth and non-porous surfaces of these plastics make it challenging for the adhesive to create a lasting bond.

Metals And Super Glue

Super glue is known for its exceptional adhesive properties, but when it comes to metals, there are certain considerations to keep in mind.

While super glue can bond to many materials, including various types of plastics, ceramics, and even wood, its ability to stick to metals can vary depending on the type of metal and its surface characteristics.

Smooth Vs. Rough Metals

When it comes to metals, the surface texture plays a crucial role in determining how well super glue will stick. Smooth metals, such as stainless steel or aluminum, provide a relatively low surface area for the glue to bond to, making it more challenging for the adhesive to form a strong bond.

On the other hand, rough or porous metals, like cast iron or bronze, offer more surface area for the glue to adhere to, resulting in a stronger bond.

Preparation For Better Adhesion

Preparation is key when it comes to achieving optimal adhesion between super glue and metals. To improve the bond, it is essential to clean the metal surface thoroughly. Any dirt, dust, or grease can interfere with the adhesive’s ability to attach to the metal. Using a mild detergent or rubbing alcohol, clean the metal surface and ensure it is dry before applying the super glue.

Additionally, roughening the surface of smooth metals using sandpaper or a file can create tiny grooves or scratches that provide more grip for the glue. This technique, known as surface roughening or scoring, can significantly enhance the adhesive bond between super glue and smooth metals.

Remember to follow the manufacturer’s instructions when using super glue, as different brands may have specific recommendations for bonding metals. It’s also important to note that while super glue can create a strong bond with many materials, there may be certain metals or metal coatings that are resistant to its adhesive properties.

In such cases, it’s advisable to explore alternative bonding methods or seek specialized adhesives designed for those specific metal surfaces.

Natural Materials Immune To Super Glue

Super Glue does not stick to natural materials such as wood, leather, and cotton. These materials have a porous surface that prevents the glue from creating a strong bond.

Super glue is a remarkable adhesive that can stick almost anything together, but there are natural materials that are immune to its bond.

These materials possess a surface that is non-porous, oily, or waxy, making it difficult for the glue to adhere. In this article, we’ll explore some of the natural materials that are immune to super glue and why they are resistant.

Wood And Super Glue

Wood is a natural material that is immune to super glue. This is because wood has a porous surface that absorbs the glue, preventing it from forming a strong bond.

Additionally, the natural oils and resins in wood make it difficult for the glue to stick. However, if you’re looking to glue wood together, there are specialized wood glues available that are designed to penetrate the wood fibers, resulting in a strong bond.

Leathers And Fabrics

Leathers and fabrics are also natural materials that are immune to super glue. They have a porous surface that absorbs the glue, preventing it from forming a strong bond. Additionally, the natural oils and waxes present in these materials make it difficult for the glue to stick.

If you’re looking to glue leathers or fabrics together, there are specialized fabric glues available that are designed to penetrate the fibers, resulting in a strong bond. In conclusion, super glue is a versatile adhesive that can bond almost anything together, but there are natural materials that are immune to its bond.

Wood, leathers, and fabrics have a surface that is porous, oily, or waxy, making it difficult for the glue to adhere. However, there are specialized glues available that are designed to penetrate these natural materials, resulting in a strong bond.

The Effect Of Conditions On Adhesion

When it comes to the adhesive properties of super glue, understanding the effect of conditions on adhesion is crucial. Factors such as temperature, humidity, surface area, and pressure can significantly impact the bonding strength of super glue.

By exploring these elements, we can gain insights into what super glue does not stick to and how environmental conditions play a pivotal role in its adhesive capabilities.

Temperature And Humidity

Temperature and humidity are pivotal factors that influence the adhesion of super glue. Extreme temperatures can alter the viscosity of the adhesive, affecting its ability to bond effectively.

Similarly, high levels of humidity can impact the curing process of super glue, potentially weakening its adhesive properties. Therefore, maintaining optimal temperature and humidity levels is essential for maximizing the bonding strength of super glue.

Surface Area And Pressure

The surface area and pressure exerted during the bonding process also play a significant role in determining the effectiveness of super glue. A larger surface area provides more contact points for the adhesive to bond, enhancing its overall strength.

Additionally, applying adequate pressure during the bonding process ensures proper contact between the surfaces, facilitating a strong and durable bond. Understanding the influence of surface area and pressure can help optimize the adhesion of super glue across various materials and applications.

Tips For Dealing With Stubborn Surfaces

When it comes to using super glue, dealing with stubborn surfaces can be a challenge. Understanding the techniques for treating surfaces and choosing the right adhesive is essential for successful bonding. Here are some tips for dealing with surfaces that super glue may not stick to.

Surface Treatment Techniques

Surface preparation is crucial for creating a strong bond with super glue. Here are some effective techniques for treating stubborn surfaces:

- Clean the surface thoroughly with a mild detergent to remove any dirt, oil, or grease.

- Use sandpaper to roughen smooth surfaces, providing a better texture for the adhesive to grip onto.

- Apply a primer or adhesion promoter specifically designed for the material you are bonding.

Choosing The Right Adhesive

Not all adhesives are suitable for every material. Consider these factors when selecting the right adhesive:

- Identify the materials being bonded and choose an adhesive designed for those specific materials.

- Consider the environmental conditions the bond will be exposed to, such as temperature and moisture.

- Ensure the adhesive has the appropriate set time and cure time for the application.

Frequently Asked Questions

What Can You Not Use Super Glue On?

Super glue should not be used on certain materials such as fabrics, porous surfaces, glass, or flexible plastics. It is best suited for bonding non-porous surfaces like metal, ceramics, or hard plastics.

Does Superglue Stick To Aluminum Foil?

Yes, superglue can stick to aluminum foil. The strong adhesive properties of superglue bond well with aluminum foil surfaces.

What Surface Does Glue Not Stick To?

Glue does not stick to nonporous surfaces like glass, metal, and plastic.

Does Super Glue Stick To Plastic?

Yes, super glue can stick to plastic due to its strong adhesive properties. It forms a durable bond with various types of plastic surfaces.

Conclusion

Knowing what Super Glue doesn’t stick to can be handy. Remember, avoid using it on polyethylene or polypropylene plastics. Understanding its limitations ensures successful bonding in various projects.

Stay informed and choose the right adhesive for your specific materials. Experiment and discover the perfect bonding solutions.