Jb Weld Marine is specifically formulated for underwater repairs, while Jb Weld Original is a versatile epoxy for a wide range of applications. Jb Weld Marine is designed for use in marine environments, making it ideal for fixing leaks or cracks in boats, kayaks, or other watercraft.

On the other hand, Jb Weld Original is suitable for bonding metal, wood, plastic, ceramic, and many other materials.

Both products offer strong and durable adhesion, but Jb Weld Marine excels in underwater environments due to its water-resistant properties.

Whether you need to repair a boat or fix everyday items, choosing the right Jb Weld product depends on the specific application and environment.

Contents

Composition

Jb Weld is a reputable brand known for its reliable and durable epoxy adhesives. When it comes to choosing between Jb Weld Marine and Jb Weld Original, understanding their composition can help make an informed decision.

Materials Used In Jb Weld Marine

Jb Weld Marine is specifically formulated to withstand harsh marine environments. It is composed of a professional-grade epoxy compound reinforced with toughened marine-grade fibers, making it resistant to saltwater, chemicals, and other environmental elements commonly encountered on boats and other marine equipment.

Materials Used In Jb Weld Original

On the other hand, Jb Weld Original is designed for versatile applications in different settings.

Its composition includes a high-strength epoxy resin and hardener, providing strong and lasting bonds on various materials such as metal, wood, plastic, ceramic, and more. This makes it an ideal choice for general repairs and projects.

In both formulas, the epoxy-based composition ensures reliable adhesion and strength, but the specific materials used enable each product to excel in its designated application.

Application Areas

J-B Weld Marine is designed for use in underwater or wet applications, making it ideal for repairs on boats, water tanks, and other marine equipment.

On the other hand, J-B Weld Original is suitable for a wide range of applications, including automotive, plumbing, and household repairs. Both products offer strong and durable bonding, but their specific application areas differ.

Application Areas When deciding between J-B Weld Marine and J-B Weld Original, it’s essential to consider their respective application areas. Both products excel in various situations, making it crucial to understand where each one works best.

Where Jb Weld Marine Works Best J-B Weld Marine is specifically formulated for underwater or water-based applications. Its design ensures that it can withstand exposure to water, making it perfect for marine repairs.

It is ideal for fixing watercraft, such as boats, as well as various water-based equipment and structures. Where Jb Weld Original Excels On the other hand, J-B Weld Original excels in a wide range of applications, primarily those that are not constantly exposed to water.

It is suitable for repairing automotive parts, household items, and machinery, making it a versatile option for numerous repair projects. In summary, the choice between J-B Weld Marine and J-B Weld Original ultimately depends on the specific application area.

While J-B Weld Marine is best suited for water-based repairs, J-B Weld Original is more versatile and suitable for a broader range of non-marine applications.

Performance

Jb Weld Marine offers superior performance compared to the original Jb Weld. Its advanced formula ensures strong and long-lasting bonds in marine environments, making it the ideal choice for boat repairs and maintenance.

Strength And Durability Of Jb Weld Marine

Jb Weld Marine is specifically designed for marine environments, offering exceptional strength and durability to withstand harsh conditions.

- Waterproof: Marine epoxy is resistant to water, making it ideal for underwater repairs.

- Corrosion Protection: Protects against rust and corrosion in marine settings.

- Long-lasting: Provides a secure bond that can endure the rigors of boating and marine activities.

Strength And Durability Of Jb Weld Original

Jb Weld Original is a versatile epoxy adhesive known for its robust strength and durability in a wide range of applications.

- Multi-surface: Bonds effectively to various materials including metal, wood, plastic, and more.

- Heat Resistant: Withstands high temperatures, making it suitable for mechanical repairs.

- Durable: Offers long-lasting results for both indoor and outdoor projects.

Water Resistance

When it comes to choosing a trustworthy adhesive for marine applications, water resistance is a critical factor to consider.

Both Jb Weld Marine and Jb Weld Original have shown remarkable results in providing superior adhesion, but how do they fare when it comes to staying strong in wet or submerged conditions?

Let’s dive into the waterproof properties of each variant to help you make an informed decision.

Waterproof Properties Of Jb Weld Marine

Jb Weld Marine is explicitly designed to withstand exposure to water, making it an excellent choice for various marine repairs and projects.

Its advanced formulation creates a tight, permanent bond that is highly resistant to water, even in extreme conditions.

- Waterproof formulation ensures a strong and durable bond in wet or underwater environments.

- Cures to a dark gray color, offering an aesthetically pleasing finish for marine applications.

- Resistant to saltwater, chemicals, and other harsh elements commonly encountered in marine environments.

- Withstands high temperatures and maintains its adhesive properties, ensuring reliability in hot conditions.

- Provides excellent resistance to vibration, shock, and impacts, guaranteeing lasting durability.

Waterproof Properties Of Jb Weld Original

In comparison, Jb Weld Original also offers commendable water resistance, although it is primarily designed for general-purpose repairs.

While it may not have the specialized formulation of Jb Weld Marine, it still provides a reliable bond even when exposed to water.

- Provides a water-resistant bond, suitable for various applications where exposure to moisture is a concern.

- Creates a strong and permanent bond, ensuring long-lasting repair or fabrication.

- Resistant to mild chemicals and household fluids, offering versatility in everyday repairs.

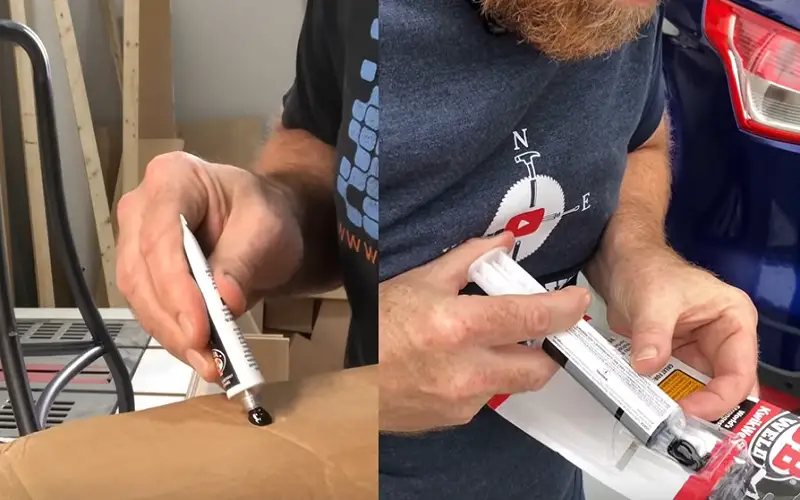

- Easy to use, with a simple mixing ratio and a convenient application process.

- Dries to a dark gray color, blending well with most surfaces for a seamless finish.

Both Jb Weld Marine and Jb Weld Original possess commendable water resistance properties, allowing you to tackle projects that involve exposure to moisture.

However, for marine-specific applications, the specialized formulation of Jb Weld Marine makes it the ideal choice to ensure a robust and enduring bond.

Curing Time

Curing time for Jb Weld Marine and Original varies, with Marine offering quicker bonding in wet conditions. Original sets in around 4-6 hours, while Marine cures in 4-6 hours underwater. Choose the best option based on your repair needs.

Drying Time Of Jb Weld Marine

When it comes to the curing time of Jb Weld Marine, it is important to consider its drying time. The drying time is the period it takes for the epoxy to harden and become fully cured.

This is an essential factor to know, as it determines how long you need to wait before using the repaired item. Jb Weld Marine is specifically designed for use in marine applications, making it perfect for fixing leaks and cracks in boats, jet skis, and other water vessels.

Its superior strength and durability make it a reliable choice for marine repairs. And when it comes to its drying time, Jb Weld Marine doesn’t disappoint.

- The drying time for Jb Weld Marine is approximately 4-6 hours.

- You’ll need to allow this time for the epoxy to fully harden and cure.

- During this period, it is important to ensure that the repaired item is kept in a dry and well-ventilated area.

- Once the epoxy has dried, you can expect it to have a strong bond and excellent resistance to water, chemicals, and temperature fluctuations.

- Jb Weld Marine is designed to withstand the harsh conditions of marine environments, so you can trust it to provide long-lasting repairs.

- After the 4-6 hour drying time, you can use the repaired item with confidence, knowing that it will hold up well against the challenges of water and weather.

Drying Time Of Jb Weld Original

Now let’s shift our focus to Jb Weld Original, the versatile and reliable epoxy adhesive that has become a go-to choice for various repair jobs. When it comes to the drying time for Jb Weld Original, there are a few key factors to keep in mind.

Jb Weld Original is known for its exceptional bonding strength and its ability to adhere to a wide range of surfaces.

Whether you need to fix a crack in metal, plastic, wood, or even concrete, Jb Weld Original can get the job done. And when it comes to its drying time, here’s what you need to know:

- The drying time for Jb Weld Original is approximately 4-6 hours.

- During this time, it is important to ensure that the repaired item is kept stationary and untouched.

- Once the epoxy has fully dried and cured, you can rely on its strong bond and resistance to heat, chemicals, and vibrations.

- Jb Weld Original dries to a dark grey color, blending seamlessly with many materials.

- After the 4-6 hour drying time, you can confidently use the repaired item, knowing that it is securely fixed and will withstand the test of time.

In conclusion, both Jb Weld Marine and Jb Weld Original offer impressive curing times, with a drying time of approximately 4-6 hours for each.

Whether you’re repairing a marine vessel or tackling a household project, these reliable epoxy adhesives deliver the strength and durability you need.

Color Options

Variety Of Colors In Jb Weld Marine

Jb Weld Marine offers a wide range of vibrant colors:

- White

- Clear

- Black

These options allow you to match the repair seamlessly with your marine equipment.

Color Choices In Jb Weld Original

Jb Weld Original provides classic color choices:

- Grey

- Dark grey

- Steel

The color selection ensures your repair blends in seamlessly with various surfaces.

Cost Comparison

When choosing the right adhesive for your marine or general repair needs, considering the cost is essential. Comparing the prices of Jb Weld Marine and Jb Weld Original can help you make an informed decision based on your budget and requirements.

Price Analysis Of Jb Weld Marine

Jb Weld Marine is designed specifically for repairs in marine environments, offering a strong bond that is resistant to water, oil, and chemicals.

The cost of Jb Weld Marine typically ranges from $6 to $10 for a small 2 oz. tube, while larger quantities, such as a 10 oz. tube, may range from $15 to $20.

Price Analysis Of Jb Weld Original

Jb Weld Original is a versatile adhesive suitable for various applications, providing a durable bond for both marine and general repairs.

The price of Jb Weld Original is usually between $5 to $8 for a 2 oz. tube, while a 10 oz. tube may cost between $10 to $15.

Frequently Asked Questions For Jb Weld Marine Vs Original

What Is The Difference Between Jb Weld And Jb Marineweld?

JB Weld is a versatile metal epoxy, while JB MarineWeld is specifically designed for marine applications. Both offer strong, durable bonds.

What Is Jb Weld Marine Epoxy Used For?

JB Weld marine epoxy is used for bonding, sealing, and repairing marine surfaces and materials.

It is designed specifically for use in underwater and water-seamed applications, providing a strong, durable, and waterproof bond.

Will Regular Jb Weld Cure Underwater?

Yes, regular JB Weld can cure underwater as it is a waterproof adhesive. However, it is important to adhere to the product’s instructions for best results.

Does Jb Marine Weld Harden?

Yes, JB Marine Weld hardens once it cures completely. It forms a strong and durable bond after drying.

Conclusion

After comparing Jb Weld Marine and Jb Weld Original, it’s clear that both are durable and versatile options for various marine applications.

Consider your specific needs and application requirements to determine which one suits your project best. Choose the right one for a strong and reliable repair solution.