Loctite 222 is a low-strength threadlocker that is ideal for small screws and fasteners, while Loctite 243 is a medium-strength threadlocker suitable for general-purpose fastening. Both products are quality solutions for preventing loosening and securing threaded assemblies.

Threadlockers are essential for securing screws and fasteners to prevent loosening due to vibration or other external forces. Two popular options in the market are Loctite 222 and Loctite 243. Loctite 222 is a low-strength threadlocker specifically designed for use on small screws and fasteners.

Its unique formula ensures a secure hold without compromising ease of disassembly. On the other hand, Loctite 243 is a medium-strength threadlocker that offers a wider range of applications, making it suitable for general-purpose fastening.

This high-quality product provides excellent resistance to vibration and environmental factors, ensuring reliable and durable connections. Whether you require a low-strength solution for small components or a medium-strength option for various applications, both Loctite 222 and Loctite 243 have you covered.

Contents

Loctite 222

Loctite 222 is a low-strength, purple-colored threadlocker designed for securing and sealing small, threaded fasteners. Its unique formulation makes it ideal for applications where adjustments or disassembly may be required in the future.

Features

Loctite 222 offers several key features that make it popular among users:

- Low-strength formulation

- Purple color for easy identification

- Ideal for small, threaded fasteners

- Prevents loosening due to vibration

- Seals and secures the threads

Applications

Due to its unique properties, Loctite 222 is widely used in various applications, such as:

- Electrical connectors

- Instrumentation panels

- Set screws and other small fasteners

- Control system components

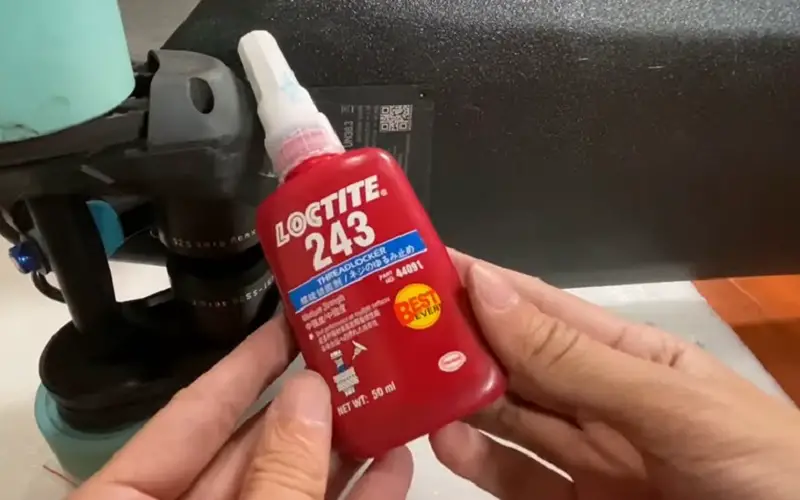

Loctite 243

Loctite 243, a medium strength threadlocker, is a popular choice for securing and sealing bolts, screws, and nuts. Its reliable and versatile nature makes it a go-to solution for various industries and applications.

Features

- Medium strength formula

- Ideal for small screws and bolts

- Prevents loosening from shock and vibration

- Provides reliable sealing and protection

- Resistant to oil, chemicals, and typical industrial fluids

Applications

Loctite 243 finds wide-ranging applications across industries including:

- Automotive maintenance and repair

- Manufacturing and assembly

- Aerospace engineering

- Heavy equipment maintenance

- General machinery maintenance

Differences Between Loctite 222 And 243

Loctite 222 is designed for small screws and fasteners and provides a low-strength, easy-to-remove solution, while Loctite 243 is suitable for larger fasteners and provides a medium-strength, removable solution.

Both products offer different strengths and applications, so it’s essential to choose the right one for your specific needs.

Strength And Cure Time

Loctite 222 provides low strength and is primarily used for securing small screws. On the other hand, Loctite 243 offers medium strength and quicker cure time, making it ideal for more heavy-duty applications.

Color And Chemical Composition

Loctite 222 is typically purple in color, while Loctite 243 comes in blue. The chemical composition of Loctite 222 allows for easier disassembly with standard hand tools, while Loctite 243 offers more resistance to vibration and impact.

Ideal Applications

- Loctite 222 is suitable for securing screws in delicate instruments and electronic devices.

- Loctite 243 is recommended for applications where higher strength and resistance to harsh conditions are required, such as automotive assemblies.

By understanding the differences between Loctite 222 and 243 in terms of strength and cure time, color and chemical composition, and ideal applications, you can choose the right adhesive for your specific needs.

How To Choose Between Loctite 222 And 243?

Choose the appropriate Loctite product based on your specific needs. Loctite 222 is suitable for smaller screws and has low strength, while Loctite 243 is designed for larger screws with medium strength. Consider the application and required strength to make the right choice.

How to Choose Between Loctite 222 and 243 Factors to Consider When deciding between Loctite 222 and 243, several important factors come into play. Taking these factors into consideration will help you make an informed decision and choose the right Loctite product for your needs.

Here are some key factors to consider:

Strength Requirements: The first factor to consider is the strength required for your application. Both Loctite 222 and 243 offer different levels of strength. Loctite 222 is a low-strength threadlocker, perfect for securing small screws, bolts, and nuts.

On the other hand, Loctite 243 is a medium-strength threadlocker that provides a stronger bond, suitable for applications that require more holding power.

Prevent Loose Connections: If you want to prevent loose connections and vibrations in your application, then both Loctite 222 and 243 are excellent choices. They are specifically designed to create a secure bond and resist loosening caused by vibrations, shocks, and temperature changes.

Operating Conditions: Consider the operating conditions of your application. If your application will be exposed to high temperatures, chemicals, or harsh environments, Loctite 243 might be the better option. It is designed to withstand more extreme conditions compared to Loctite 222.

Removability: Another important factor is removability. If you anticipate the need for disassembly or repair in the future, Loctite 222 is the go-to option. Being a low-strength threadlocker, it allows for easy removal of fasteners without causing damage.

Loctite 243, although removable, may require more effort and heat to disassemble. Best Practices To ensure the best performance and results when using Loctite 222 or 243, it’s important to follow these best practices.

Clean Surfaces: Before applying the threadlocker, make sure all surfaces are clean, dry, and free from grease, oil, and dirt. Use a suitable cleaning agent to remove any contaminants and ensure maximum adhesion.

Apply the Right Amount: Apply the threadlocker sparingly to avoid excess adhesive that can interfere with the fastening process. Follow the recommended usage instructions provided by Loctite for the specific product you choose.

Allow Ample Curing Time: Give the threadlocker enough time to fully cure and create a strong bond. This will ensure optimal performance and prevent any loosening or failures in the future. Refer to the product instructions for the curing time required.

Store Properly: After use, make sure to store the Loctite product in a cool and dry place, away from direct sunlight and extreme temperatures. This will help preserve its effectiveness and extend its shelf life.

In summary, when choosing between Loctite 222 and 243, consider factors such as strength requirements, operating conditions, removability, and follow best practices to ensure optimal results.

By carefully evaluating these factors and following the recommended guidelines, you can select the right Loctite threadlocker for your specific application and achieve reliable and long-lasting results.

Tips For Effective Threadlocking

Threadlocking is an essential process that ensures the secure assembly of threaded fasteners, preventing them from coming loose due to vibrations or other external forces.

Whether you’re using Loctite 222 or Loctite 243, it’s crucial to follow the right tips for effective threadlocking.

In this article, we will delve into the details of surface preparation and application techniques, ensuring you achieve a reliable and durable threadlocking solution.

Surface Preparation

Proper surface preparation is the first step to ensure effective threadlocking. Here are the key factors to consider:

- Cleanliness: Make sure the surfaces to be bonded are clean, free from oil, grease, dust, and other contaminants. You can use a mild solvent or cleaner to remove any residue.

- Roughness: Create a slightly rough surface by lightly abrading it with fine grit sandpaper. This improves the adhesion of the threadlocker to the substrate.

- Dryness: Ensure that the surfaces are completely dry before applying the threadlocker. Moisture can affect the cure and performance of the adhesive.

Application Techniques

To achieve optimal threadlocking results, the right application technique is crucial. Consider the following tips:

- Apply the Right Amount: Use only a small amount of threadlocker to avoid excess and minimize the risk of contamination. A drop or two is usually sufficient for most applications.

- Distribute Evenly: Ensure the threadlocker is distributed evenly along the thread and throughout the engaged area. This helps in achieving consistent, reliable threadlocking.

- Allow for Curing Time: After applying the threadlocker, allow sufficient time for it to cure before subjecting the assembly to any load or stress. Follow the manufacturer’s recommendations for curing time.

By following these tips for surface preparation and application techniques, you can enhance the effectiveness of your threadlocking process.

Whether you choose Loctite 222 or Loctite 243, these guidelines will guide you towards achieving secure and long-lasting threadlocked assemblies.

Remember, proper threadlocking not only provides reliability but also ensures the longevity of your projects.

Common Myths About Threadlockers

Myth 1: Threadlockers Only For Professionals

Let’s debunk the myth that threadlockers are reserved only for professionals.

Threadlockers like Loctite 222 and 243 are easy for anyone to use, from DIY enthusiasts to industry professionals.

- Threadlockers enhance the performance of threaded fasteners in various applications.

- Even individuals with basic mechanical skills can benefit from using threadlockers.

Don’t let the misconception deter you from utilizing the many advantages that threadlockers offer.

Myth 2: Threadlockers Are Permanent

Another misconception about threadlockers is that they are permanent solutions.

Contrary to this belief, Loctite 222 and 243 provide a balance of strength and removability.

- While they secure fasteners effectively, they can still be disassembled when needed.

- Threadlockers offer both security and flexibility, making them versatile for a range of applications.

Understanding the true nature of threadlockers can help you utilize them optimally in your projects.

Frequently Asked Questions On Loctite 222 Vs 243

What Is The Difference Between 243 And 222 Loctite?

The difference between 243 and 222 Loctite lies in their curing strength and temperature resistance.

Loctite 243 offers stronger bonding and higher temperature resistance than Loctite 222. Choose 243 for heavier-duty applications and 222 for smaller, more delicate projects.

What Is Loctite 222 Used For?

Loctite 222 is used for securing and sealing of threaded fasteners to prevent loosening. It is suitable for low-strength metals and has excellent chemical resistance.

What Is Loctite 243 Used For?

LOCTITE 243 is used for securing and sealing threaded fasteners to prevent loosening due to vibrations. It is commonly used in industries such as automotive, aerospace, and manufacturing.

Is Loctite 222 Permanent?

Loctite 222 is not permanent as it is a low-strength threadlocker designed for easy disassembly.

Conclusion

In choosing between Loctite 222 and 243, consider your specific needs carefully. Each has unique strengths that can benefit different applications.

While Loctite 222 is ideal for low-strength threadlocking, Loctite 243 offers medium-strength properties. Ultimately, the decision lies in the requirements of your project to ensure optimal results.