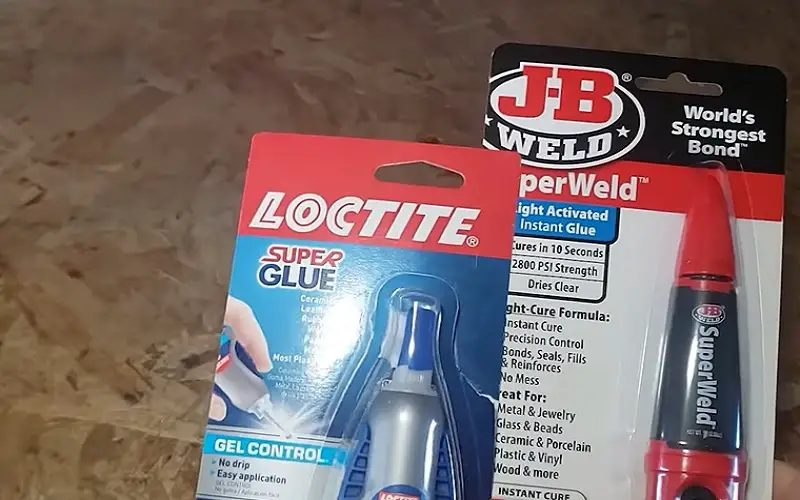

J-B Weld and Loctite are both popular adhesives for bonding various materials. When it comes to choosing between J-B Weld and Loctite, it’s important to understand the differences and advantages of each product.

J-B Weld is known for its high strength and versatility, capable of bonding materials such as metal, wood, plastic, ceramic, and more.

On the other hand, Loctite offers a wide range of specialized adhesives for different applications, including threadlockers, sealants, and super glues.

Both brands have their own loyal user base and are trusted for their reliability and effectiveness. Ultimately, the choice between J-B Weld and Loctite depends on the specific needs of your project and the materials you are working with.

Contents

Composition

Before comparing Jb Weld and Loctite, it’s essential to understand their composition. Both products are adhesives that are used for a variety of applications, and their composition plays a crucial role in determining their effectiveness.

Materials Used In JB Weld

- Steel-filled epoxy

- Resin

- Hardener

- Iron powder

Materials Used In Loctite

- Cyanoacrylate (commonly known as super glue)

- Plastifiers

- Solvents

- Stabilizers

Strength And Durability

When choosing between J-B Weld and Loctite for your bonding needs, considering the strength and durability of each product is crucial.

Both brands are renowned for their reliability, but it’s essential to understand the nuances of their strength and durability to make an informed decision.

Comparison Of Strength

J-B Weld: J-B Weld is widely recognized for its formidable strength, particularly in high-stress applications. Its bond strength is attributed to its two-part epoxy formula, providing a resilient bond that can withstand significant pressure and heavy loads.

Loctite: Loctite’s strength lies in its versatile range of adhesives, catering to various bonding requirements. Whether it’s super glues or structural adhesives, Loctite offers a spectrum of options with impressive cohesion and adhesion strength.

Comparison Of Durability

J-B Weld: Known for its exceptional durability, J-B Weld forms a resilient bond that is resistant to harsh environmental conditions, including extreme temperatures, moisture, and various chemicals. This durability ensures longevity and reliability in diverse applications.

Loctite: Equally durable, Loctite’s adhesives exhibit resistance to environmental stressors, ensuring long-lasting performance. Whether it’s for indoor or outdoor applications, Loctite’s durability makes it a dependable choice for various bonding needs.

Application Areas

Application Areas: J-B Weld and Loctite are two popular choices when it comes to adhesive products for various applications. Let’s explore their usage in different areas:

Uses In Automotive Industry

J-B Weld and Loctite find extensive applications in the automotive industry due to their strong bonding capabilities and durability.

- Engine Repairs: Ideal for fixing cracks in engine blocks or sealing leaks in the cooling system.

- Exhaust Systems: Used to bond exhaust components like mufflers and catalytic converters.

Uses In Household Repairs

These adhesives are also valuable for household repairs, offering strength and versatility for a range of fixes.

- Metal Repairs: Great for fixing metal items such as pipes, tools, or kitchen appliances.

- Plumbing: Effective in sealing leaks in pipes or repairing fittings efficiently.

Drying Time

When it comes to selecting the right adhesive for your projects, it’s important to consider the drying time.

The drying time of an adhesive determines how long it takes for the adhesive to fully set and bond two surfaces together. This is a crucial factor to consider, as it can affect the overall efficiency of your project.

Jb Weld Drying Time

Jb Weld is a popular adhesive known for its strength and versatility. When it comes to drying time, Jb Weld requires an ample amount of time to set completely.

On average, it takes around 4-6 hours for Jb Weld to dry to the touch. However, it is essential to note that the full cure time for Jb Weld is 15-24 hours.

This means that it can take up to a day for Jb Weld to reach its maximum bond strength. During the drying period, it’s crucial to ensure that the surfaces being bonded are held firmly together.

Applying pressure to the joined surfaces can aid in achieving a strong bond. Patience is important with Jb Weld, as allowing it the necessary time to fully cure will result in a more durable and reliable bond.

Loctite Drying Time

Loctite is another popular adhesive choice for a wide range of applications. Unlike Jb Weld, Loctite offers quicker drying times.

On average, Loctite takes approximately 5-10 minutes to dry to the touch. This fast-drying feature of Loctite can be advantageous for projects that require a quick turnaround time.

However, it is worth noting that while Loctite dries quickly, it does not fully cure right away. The complete curing process for Loctite typically takes anywhere from 24 to 48 hours.

During this time, it is recommended to avoid putting a heavy load or stress on the bonded surfaces to allow the adhesive to reach its maximum strength.

It is important to adhere to the recommended drying and curing times for both Jb Weld and Loctite to achieve the best results.

Rushing the process can compromise the strength and reliability of the bond. By following the recommended guidelines, you can ensure a strong and long-lasting bond for your projects.

Temperature Resistance

Temperature resistance is a crucial factor to consider when choosing between Jb Weld and Loctite. Both brands offer adhesive solutions for various applications, but how well do they hold up against high temperatures? Let’s dive into the heat resistance of Jb Weld and Loctite to help you make an informed decision.

Heat Resistance Of Jb Weld

Jb Weld is well-known for its exceptional heat resistance, making it a reliable choice for projects that involve exposure to high temperatures. With a temperature resistance of up to 500 degrees Fahrenheit (260 degrees Celsius), Jb Weld can withstand intense heat without losing its bonding strength. This makes it ideal for automotive repairs, such as fixing exhaust systems or repairing engine parts.

Heat Resistance Of Loctite

Loctite also offers impressive heat resistance, ensuring that your bonded materials stay secure even in extreme temperature conditions. With a temperature resistance of up to 300 degrees Fahrenheit (150 degrees Celsius), Loctite provides a reliable bond that can withstand the heat generated by electrical components or applications where moderate heat exposure is expected.

It is important to note that the heat resistance of Jb Weld surpasses that of Loctite, as Jb Weld can tolerate higher temperature thresholds. Depending on your specific project requirements, this difference in temperature resistance can be a key factor to consider when making your choice between Jb Weld and Loctite.

Waterproofing

Waterproofing is a crucial factor to consider when choosing between Jb Weld and Loctite for your sealing needs.

Waterproofing Ability Of Jb Weld

Jb Weld offers exceptional waterproofing, creating a strong and impermeable seal that effectively protects against water damage.

Waterproofing Ability Of Loctite

Loctite is renowned for its superior waterproofing capabilities, ensuring that the bond remains intact even in wet and humid conditions.

Cost-effectiveness

When considering the cost-effectiveness of Jb Weld versus Loctite, it’s essential to compare their performance, durability, and long-term value.

Both products offer a balance between quality and price, providing users with dependable solutions for their bonding and sealing needs.

By carefully evaluating the specific requirements of the project at hand, individuals can make an informed decision that suits their budget while ensuring reliable results.

Cost-effectiveness plays a significant role in the decision-making process when choosing between J-B Weld and Loctite. Let’s delve into the comparison of costs and value for money of these two popular adhesive products.

Comparison Of Costs

When it comes to upfront costs, J-B Weld tends to be slightly cheaper than Loctite. Usually, this cost disparity is observable in the initial purchase price.

Value For Money

In terms of value for money, both J-B Weld and Loctite provide durable and reliable bonding solutions, making them a worthwhile investment. However, J-B Weld often stands out for its longevity and solid performance, offering excellent value over the long term.

In conclusion, while both products have their strengths, J-B Weld generally proves to be the more cost-effective option, delivering exceptional value for money in the long run.

Frequently Asked Questions For Jb Weld Vs Loctite

What Glue Is Stronger Than J-b Weld?

Gorilla Glue is noted to be stronger than J-B Weld in many applications due to its exceptional bonding strength, versatility, and water resistance. It is a reliable choice for various materials and offers a strong alternative to J-B Weld.

Is Loctite As Strong As A Weld?

Yes, Loctite can be as strong as a weld when used correctly for bonding materials.

Can J-b Weld Be Used As Thread Lock?

Yes, J-B Weld can be used as a thread lock. It provides a strong and durable bond to secure fasteners, preventing them from loosening over time. Apply a small amount to the threads and allow it to cure for optimal results.

What’s Better Than Loctite?

3M Scotch-Weld is a strong adhesive similar to Loctite, providing reliable bond strength.

Conclusion

After comparing Jb Weld and Loctite, it’s clear both have their strengths and applications. Ultimately, the choice between them comes down to your specific needs and preferences.

Remember to consider factors like strength, curing time, and ease of use before making a decision. Both products are versatile and reliable in their own right, so choose wisely based on your project requirements.