To make wood clamps, start by cutting two wooden boards to your desired length and width. Then, drill holes in each board and insert threaded rods through the holes.

Tighten nuts onto the rods to secure the boards together, creating a clamp. Finally, attach rubber pads to the clamping surfaces for added grip. Voila! You have your very own homemade wood clamps. Creating your own wood clamps can be a cost-effective and convenient solution for aspiring woodworkers or DIY enthusiasts.

By following a few simple steps, you can make clamps that are tailored to your specific project needs. These homemade clamps can securely hold pieces of wood together during various woodworking tasks. Whether you need to glue, saw, or shape wooden pieces, having a sturdy and reliable clamp is essential to ensure precise and accurate results.

In this guide, we will explore the process of making wood clamps, providing you with the necessary steps and tips to successfully create your own clamps at home. So, let’s dive in and discover how you can make wood clamps for your woodworking endeavors.

Contents

Materials And Tools

When it comes to making wood clamps, having the right materials and tools is key. Below is a breakdown of the required materials and essential tools you need for this DIY project.

Required Materials

- Wood: Choose a sturdy wood such as oak or maple.

- Threaded Rods: To create the tightening mechanism.

- Nuts and Washers: For securing the rods and providing stability.

- Wood Glue: To bond the pieces together securely.

Essential Tools

- Saw: For cutting the wood to the desired lengths.

- Drill: To create holes for the rods to pass through.

- Clamps: To hold the wood in place during assembly.

- Sandpaper: For smoothing rough edges.

- Measuring Tape: To ensure accurate cuts and placements.

Choosing The Right Wood

When making wood clamps, choosing the right wood is crucial for ensuring the strength and durability of the finished product.

The type of wood you select will impact the clamp’s ability to withstand pressure and maintain a secure grip. It is essential to consider various properties and characteristics when choosing the wood for your clamps.

Properties To Look For

When selecting wood for making clamps, it’s important to consider certain properties to ensure the effectiveness and longevity of the clamps.

Here are some key properties to look for:

- Strength

- Stiffness

- Density

- Resistance to warping

Common Types Of Wood For Clamps

There are several common types of wood that are well-suited for crafting clamps due to their specific characteristics.

These woods are often chosen for their strength and durability, making them ideal for crafting reliable and sturdy clamps. Some common types of wood for clamps include:

- Maple

- Oak

- Walnut

- Ash

Measuring And Cutting The Wood

Making wood clamps is a gratifying project for any woodworking enthusiast. The first step in crafting your own wood clamps is measuring and cutting the wood to size.

Precise measurements and accurate cuts are crucial for the functionality of the clamps. Below, we’ll delve into the process of determining the length and width of the wood, as well as using a saw to cut the wood to size.

Determining The Length And Width

Before starting with the cutting process, determining the length and width of the wood is vital. Take into account the specific requirements of your project. Ensure that the wood pieces are appropriately sized to fit the intended purpose of the clamps.

Using A Saw To Cut The Wood

Once you have the measurements, it’s time to utilize a saw to cut the wood pieces. Aim for precise, clean cuts by using a high-quality saw. Make sure to wear the necessary safety gear, such as goggles and gloves, before cutting the wood.

Creating The Clamping Mechanism

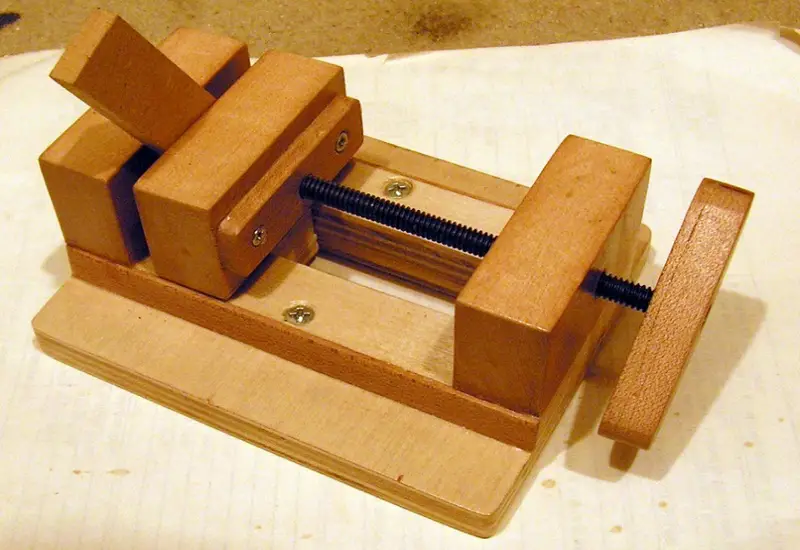

To create wood clamps, the clamping mechanism is crucial. Start by selecting the right materials, such as hardwood and metal screws. Measure and cut the wood to the desired size, then attach the metal screw to create the clamping mechanism.

This simple process will result in sturdy and reliable wood clamps. Creating the Clamping Mechanism Designing the mechanism When creating a wood clamp, designing the clamping mechanism is essential for ensuring its functionality and effectiveness.

The mechanism should be carefully planned to provide a secure grip and ease of use. Start by determining the specific dimensions and requirements for the clamping mechanism based on the intended use and size of the wood pieces to be clamped.

Consider incorporating a threaded rod or a parallel clamp design to enable precise and adjustable clamping pressure. Attaching the movable and fixed jaws Attaching the movable and fixed jaws is a crucial step in constructing the wood clamp.

The movable jaw should be capable of sliding along the length of the clamp to accommodate various sizes of wood pieces, while the fixed jaw provides a stable anchor for the mechanism.

Ensure that the jaws are securely fastened to the frame of the clamp using bolts or screws to prevent any movement or instability during use.

By following these guidelines and focusing on the details of the clamping mechanism, you can create a reliable and versatile wood clamp that meets your woodworking needs.

Assembling The Clamp

In this section, we will discuss the step-by-step process of assembling your wood clamp.

Follow these instructions carefully to ensure a sturdy and reliable clamp that will help you with your woodworking projects. You will need to apply adhesive and secure the individual parts together. Let’s get started!

Applying Adhesive

Before you begin assembling the wood clamp, it’s important to apply adhesive to ensure a strong bond between the parts.

Choose a high-quality wood glue that dries clear and is suitable for your specific woodworking needs. Here are the steps to follow:

- Gather all the clamp parts you have prepared.

- Apply a thin, even layer of wood glue to one of the mating surfaces.

- Press the mating surface against the corresponding surface of the other part.

- Apply gentle pressure to ensure proper bonding between the parts.

- Wipe off any excess glue with a damp cloth.

Remember, proper adhesive application is crucial for the stability and strength of your wood clamp, so take your time and ensure a secure bond between the parts.

Securing The Parts Together

After applying adhesive, it’s time to securely fasten the individual parts together. This step is crucial to ensure that your wood clamp functions effectively.

Follow these steps to secure the parts:

- When using screws, use a drill or screwdriver to carefully insert the screws into the pre-drilled holes. Ensure that the screws are snug, but be cautious not to over tighten and risk damaging the wood.

- If you are using nails, gently tap them into the pre-marked spots using a hammer. Be sure to fully insert the nails, taking care not to split the wood.

- If you prefer using clamps or vices, place them strategically to hold the parts together until the glue dries completely.

- Check that all parts are aligned correctly and adjust if necessary.

Securing the parts properly is essential for the overall functionality and durability of your wood clamp. Double-check each step to ensure a solid construction that can withstand the pressure and tension required during your woodworking projects.

By following these instructions, you will be able to assemble a reliable wood clamp that will help you tackle your woodworking tasks effectively.

Remember to allow sufficient time for the adhesive to dry completely before using the clamp.

Finishing Touches

Discover the key steps to crafting wood clamps for the perfect finishing touch. Unleash your creativity and practical skills with these easy to follow guidelines. Elevate your woodworking projects with homemade clamps that are both functional and stylish.

Sanding The Clamp

One of the most important steps in perfecting your wood clamp project is sanding. This ensures that the surface of your clamp is smooth and ready for the finishing touches.

Start by using a coarse-grit sandpaper to remove any rough edges or imperfections. Be sure to sand both the inside and outside surfaces of the clamp. Gradually switch to a finer-grit sandpaper to achieve a polished and even finish.

Applying Varnish Or Finish

Once you have sanded the clamp, it’s time to apply a protective varnish or finish. This step not only enhances the appearance of your wood clamp but also provides durability and resistance to damage.

Here’s how you can apply varnish or finish to your clamp:

- Clean the surface of the clamp to remove any dust or debris.

- Apply a thin and even coat of varnish or finish using a brush or cloth.

- Allow the first coat to dry completely according to the manufacturer’s instructions.

- Sand the surface lightly with fine-grit sandpaper to remove any brush strokes or bubbles.

- Apply a second coat of varnish or finish for added protection and a flawless finish.

- Allow the final coat to dry completely before using your wood clamp.

Remember, using the right type of varnish or finish for your specific wood clamp project is essential. Research different options to determine the one that suits your project best.

Additionally, consider the drying time and compatibility of the varnish or finish with wood. By following these tips for sanding and applying varnish or finish, you can ensure that your wood clamp project is completed with a professional and polished look.

Take your time during the finishing touches to achieve a high-quality end result that you can be proud of.

Tips And Safety Precautions

Tips for successful clamp making:

- Maintain proper measurements for precision.

- Use sturdy materials for durability.

- Apply glue evenly for a strong bond.

Safety precautions to follow:

- Wear safety goggles to protect eyes.

- Use gloves to safeguard hands from splinters.

- Avoid loose clothing that can get caught.

Frequently Asked Questions On How To Make Wood Clamps

What Can I Use If I Don’t Have Wood Clamps?

You can use alternatives like rope, ratchet straps, or band clamps to secure wood. Using glue or nails can also be effective.

What Makes A Good Wood Clamp?

A good wood clamp is characterized by sturdy construction, secure grip, adjustable pressure, and easy operation.

It should have a durable material that withstands the pressure and provides stability when clamping wood pieces together. A reliable wood clamp ensures precise and stable woodworking projects.

How Do You Clamp Two Pieces Of Wood Together?

To clamp two pieces of wood together, use a clamp to hold them firmly in place. Position the pieces securely and tighten the clamp to create pressure for a strong bond.

How Do You Make Wood Clamps Longer?

To make wood clamps longer, use a wooden extension block and longer screws to increase the clamping capacity.

Simply place the extension block between the clamp jaws and attach it with longer screws for added length and versatility.

Conclusion

In crafting wood clamps, precision and creativity come together in a rewarding DIY project.

The versatility of wood clamps allows for endless possibilities in woodworking.

With the right tools and techniques, anyone can successfully make their own wood clamps for various projects.