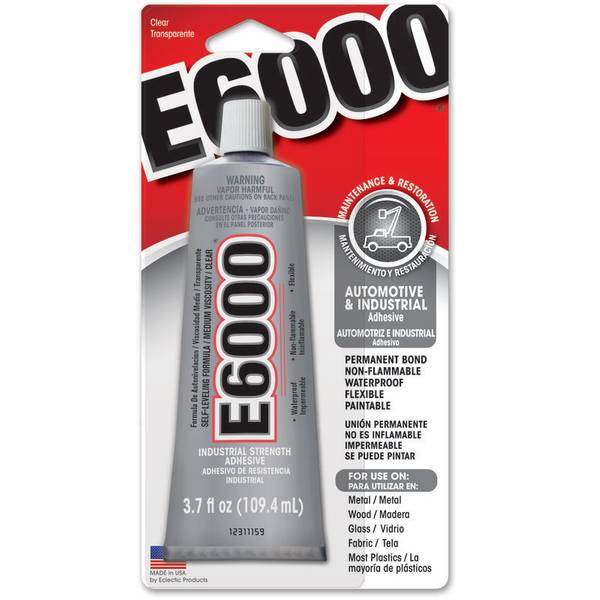

E6000 and JB Weld are two popular adhesive brands with unique characteristics for different applications. When it comes to E6000 vs JB Weld, both adhesives have their strengths and can be used for various projects.

E6000 is a versatile adhesive that offers flexibility and works well on different materials such as glass, ceramics, and plastics. On the other hand, JB Weld is a steel-reinforced epoxy adhesive that is known for its exceptional bonding strength on metal surfaces.

Whether you need a flexible adhesive or a strong bond for metal, both E6000 and JB Weld have their advantages. Ultimately, the choice depends on your specific project requirements.

Contents

E6000 Vs Jb Weld

Composition

When it comes to the composition of E6000 and Jb Weld, it’s essential to understand the materials used in each product. The composition plays a significant role in determining the performance and suitability for various applications.

Materials Used In E6000

- Ethyl Acetate: A solvent used to dissolve other substances to create the adhesive.

- Butyl Acetate: Another solvent that contributes to the adhesive properties of E6000.

- Toluene: Acts as a solvent and aids in the flow and application of the adhesive.

- Silicone: Provides flexibility and adhesion to a wide range of materials.

- Resin: Serves as the base material for the adhesive compound, providing strength and bonding capabilities.

Materials Used In Jb Weld

- Epoxy Resin: The primary bonding agent in Jb Weld, providing high strength and durability.

- Steel Particles: These enhance the strength and toughness of the epoxy when cured, making it suitable for metal repairs.

- Adhesives: Various chemical compounds that aid in bonding different materials and provide structural integrity.

- Modifying Agents: Additional substances added to customize the curing time, viscosity, and other properties of the epoxy.

Application

E6000 and Jb Weld are both popular adhesives used for a wide range of applications. The choice between E6000 and Jb Weld often comes down to the specific requirements of the project. Understanding the application of each product can help ensure the best results for your project.

Common Uses Of E6000

- Embellishing clothing and accessories

- Repairing jewelry

- Securing beads and rhinestones

- Attaching tiles and mosaics

- Bonding leather and rubber

Common Uses Of Jb Weld

- Metal repair

- Automotive repairs

- Plumbing repairs

- Household repairs

- Wood bonding

Strength And Durability

When choosing between E6000 and Jb Weld, considering the strength and durability of each adhesive is paramount. Below we delve into a comparison of the strength of E6000 and Jb Weld.

Comparing Strength Of E6000

E6000 is known for its impressive bond strength, making it ideal for a variety of crafting and repair projects. Here are some key points:

- Provides a strong and flexible bond

- Resistant to water, chemicals, and temperature changes

- Works well on a variety of materials including metal, glass, wood, and plastic

Comparing Strength Of Jb Weld

Jb Weld is a popular epoxy adhesive recognized for its durability and strength. Here are some highlights of its strength properties:

- Creates a permanent bond that is resistant to impact and vibration

- Can withstand extreme temperatures

- Ideal for heavy-duty applications such as metal bonding and automotive repairs

Flexibility

When it comes to adhesive options, flexibility is an important factor to consider. Both E6000 and Jb Weld are widely used adhesives known for their strength and versatility.

However, they differ in terms of flexibility, which can be crucial depending on your project’s requirements. Let’s take a closer look at the flexibility of E6000 and Jb Weld.

Flexibility Of E6000

E6000 is known for its exceptional flexibility, making it ideal for projects that require adhesion to materials that undergo movement, bending, or flexing.

This adhesive offers a strong bond without compromising the flexibility of the bonded materials. Whether you’re working on jewelry, fabric, rubber, or plastic, E6000 provides a durable and flexible bond that withstands various stressors.

Flexibility Of Jb Weld

Jb Weld, on the other hand, is renowned for its strength and rigidity. While it may not be as flexible as E6000, Jb Weld offers excellent structural integrity and can withstand heavy loads and high temperatures.

It is an ideal choice for projects that require a strong and rigid bond, such as automotive repairs or metal fabrication.

It’s important to note that the flexibility of E6000 and Jb Weld is determined by the specific formulation of each adhesive product. While E6000 generally offers greater flexibility, Jb Weld can still provide a reliable bond for projects that prioritize strength and rigidity over flexibility.

Drying Time

The drying time of a glue or adhesive is an important consideration when working on any project that requires bonding materials together. The E6000 and Jb Weld are two popular choices for adhesive solutions, each with its own unique drying time.

Drying Time Of E6000

E6000 is known for its fast-drying properties, making it a favorite among crafters and DIY enthusiasts. When applied, E6000 typically dries to touch within 10-15 minutes.

However, it’s important to note that the full curing time may take up to 24-72 hours, depending on various factors such as humidity, temperature, and the materials being bonded. It is recommended to allow ample time for the adhesive to fully cure before handling or putting stress on the bond.

Drying Time Of Jb Weld

Jb Weld, on the other hand, has a longer drying time compared to E6000. This epoxy adhesive typically takes about 4-6 hours to set and approximately 15-24 hours to fully cure.

Just like E6000, the curing time can also be affected by external factors such as temperature and humidity. It is important to follow the manufacturer’s instructions and allow Jb Weld to cure completely before putting any stress on the bond.

In summary, the drying time of E6000 is generally faster than Jb Weld. While E6000 dries to touch within 10-15 minutes, Jb Weld takes about 4-6 hours to set. However, both adhesives require additional curing time to achieve maximum strength and durability.

Toxicity And Safety

Comparing toxicity and safety of E6000 and Jb Weld adhesive products is crucial for proper usage. E6000 is known for its strong odor and potential skin and eye irritation, while Jb Weld is generally considered to be non-toxic and safe to use.

Understanding the potential hazards of these products is essential for safe handling and application.

Toxicity and safety are crucial aspects to consider when comparing E6000 and Jb Weld for various projects. Both adhesives have their own set of safety considerations that users need to be aware of.

Safety Considerations For E6000

E6000 contains harmful chemicals like carcinogens. Always use E6000 in a well-ventilated area. Avoid skin and eye contact with the adhesive to prevent irritation. Proper hand and eye protection are essential when working with E6000.

Safety Considerations For Jb Weld

Jb Weld has specific safety guidelines to follow. Ensure adequate ventilation when using the product. Avoid direct skin contact with Jb Weld to prevent skin irritations.

Always wear gloves and eye protection while handling Jb Weld. Remember to prioritize safety when working with any adhesive to prevent potential harmful effects.

Frequently Asked Questions For E6000 Vs Jb Weld

Is E6000 As Strong As Epoxy?

Yes, E6000 is a strong adhesive, comparable to epoxy. It is known for its durability and versatility in bonding various materials. With its strong bonding capabilities, E6000 is widely used in many applications.

What Is Stronger Than J-b Weld Glue?

J-B Weld SteelStik. It’s resistant to petroleum, chemicals, acids, and saltwater, and withstands temperatures up to 300°F.

What Will E6000 Not Stick To?

E6000 will not stick to surfaces coated in oil, plastic materials, or direct sunlight exposure.

Is E6000 Good For Metal On Metal?

Yes, E6000 is good for metal on metal. It provides a strong bond and is ideal for various metal projects.

Conclusion

In the battle of E6000 vs JB Weld, the choice ultimately depends on your specific needs. Each has its strengths and weaknesses.

Do your research to determine which adhesive is best suited for your project. Consider factors like durability, drying time, and application ease.