Yes, you can cut metal with a Dremel using the appropriate cutting wheel attachment. The Dremel rotary tool is versatile and can be equipped with cutting discs suitable for cutting through various types of metal, making it a handy tool for DIY enthusiasts and professionals alike.

The Dremel’s high-speed rotation combined with the cutting wheel’s abrasive nature allows for precise and efficient metal cutting. Whether you’re working with thin sheet metal or thicker metal rods, the Dremel can provide a controlled and accurate cutting experience.

By choosing the right cutting disc and following proper safety precautions, you can achieve clean and precise cuts on metal materials using a Dremel rotary tool.

Contents

- Introduction To Cutting Metal With A Dremel

- Choosing The Right Dremel Tool

- Essential Accessories And Attachments

- Safety First: Preparing To Cut Metal

- Step-by-step Guide To Cutting Metal

- Troubleshooting Common Issues

- Maintenance And Care For Your Dremel

- Advanced Projects And Ideas

- Frequently Asked Questions

- Conclusion

Introduction To Cutting Metal With A Dremel

Discover the versatility of a Dremel for cutting metal effortlessly. With the right attachments, a Dremel can effectively cut through various types of metal, making it a handy tool for DIY enthusiasts and professionals alike. Unleash the cutting power of a Dremel on your metal projects today.

Using a Dremel for metal cutting tasks opens up a world of possibilities for DIY enthusiasts. This versatile tool, known for its precision and ease of use, can handle various metal cutting projects with efficiency and accuracy. Whether you are a hobbyist, a craftsperson, or a professional, a Dremel can be a valuable addition to your toolkit.

Popular Uses For A Dremel In Diy Projects

- Create intricate designs on metal surfaces

- Engrave personalized messages on metal items

- Cut metal sheets for jewelry making

- Remove rust and corrosion from metal objects

Benefits Of Using A Dremel For Cutting Metal

- Precision cutting: Achieve detailed cuts with ease

- Versatility: Can be used for various metal cutting tasks

- Portability: Easy to maneuver in tight spaces

- Efficiency: Get the job done quickly and accurately

Choosing The Right Dremel Tool

When it comes to cutting metal with a Dremel, choosing the right tool is crucial for achieving precise and efficient results. With a wide array of Dremel tools available, selecting the most suitable one can be a daunting task. Let’s delve into the various types of Dremel tools and the key factors to consider when making your selection.

Types Of Dremel Tools Available

There are several types of Dremel tools designed for cutting metal, each with its own set of features and capabilities. The most common types include:

- Rotary Tools

- Oscillating Tools

- Cordless Rotary Tools

- Multi-Tools

Factors To Consider When Selecting A Dremel

When choosing a Dremel tool for cutting metal, it’s important to consider the following factors:

- Power and Speed: Ensure the tool has sufficient power and variable speed settings to handle metal cutting tasks.

- Accessory Compatibility: Look for a Dremel tool that is compatible with metal-cutting accessories such as cutting wheels and abrasive discs.

- Ergonomics: Opt for a Dremel tool that offers a comfortable grip and ergonomic design for extended use.

- Durability: Choose a durable and robust Dremel tool that can withstand the rigors of metal cutting applications.

- Price: Consider your budget and choose a Dremel tool that offers the best value for its features and capabilities.

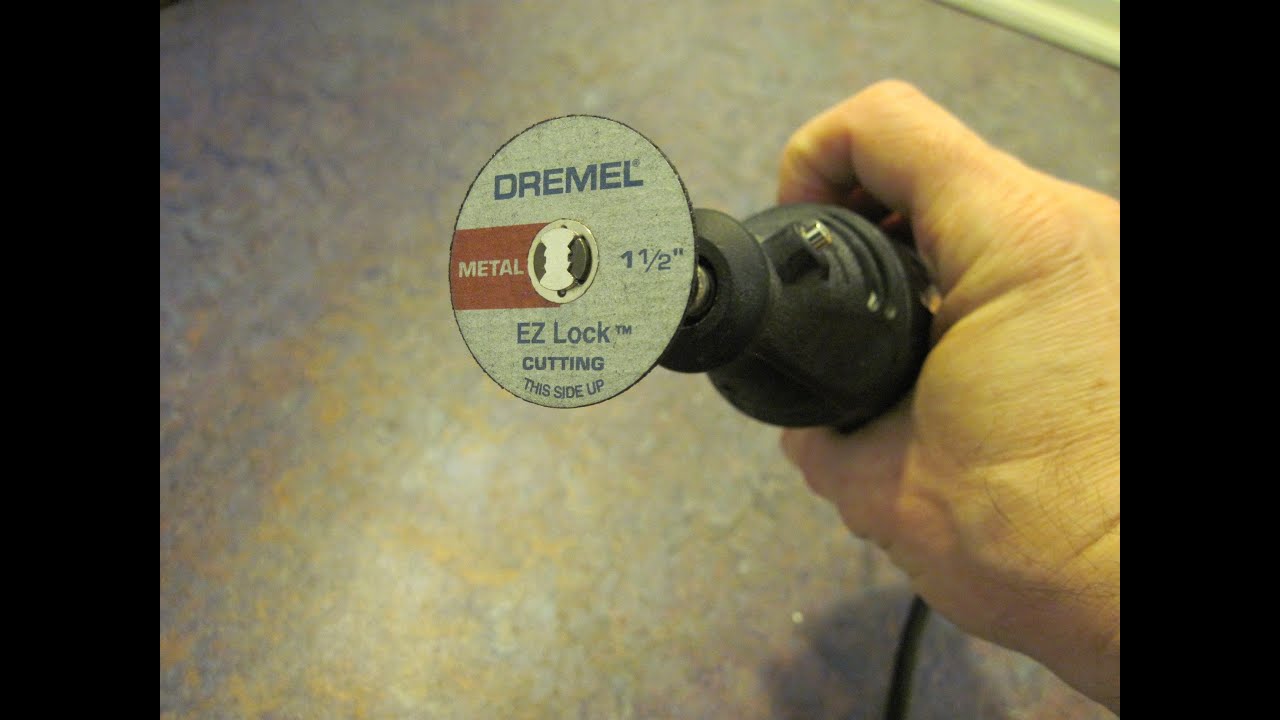

Essential Accessories And Attachments

When it comes to cutting metal with a Dremel, having the right accessories and attachments is crucial. Not only will they make the process easier and more efficient, but they will also help you achieve cleaner cuts and avoid damaging your Dremel tool.

Best Dremel Bits For Cutting Metal

The type of Dremel bit you use for cutting metal will depend on the thickness and hardness of the metal you are working with. Here are some of the best Dremel bits for cutting metal:

| Dremel Bit | Material | Use |

|---|---|---|

| 561 Multipurpose Cutting Bit | High-speed steel | Cuts through wood, plastic, fiberglass, drywall, laminate, aluminum, and vinyl siding |

| 426 Cutting Wheel | Fiberglass-reinforced | Cuts through metal, wood, plastic, and ceramic |

| 420 Cut-Off Wheel | Reinforced with fiberglass | Cuts through metal, wood, plastic, and ceramic |

Other Necessary Dremel Attachments

In addition to the cutting bits, there are other necessary attachments that will come in handy when cutting metal with a Dremel:

- Flex Shaft Attachment: Allows for greater precision and control when cutting metal in tight spaces.

- Circle Cutter Attachment: Perfect for cutting circles or curves in metal.

- Router Attachment: Can be used to create intricate designs or patterns in metal.

- Sharpening Attachment: Helps to maintain the sharpness of your Dremel bits.

By having these essential accessories and attachments, you can ensure that you are able to cut metal with your Dremel safely and effectively, while achieving the desired results.

Safety First: Preparing To Cut Metal

When it comes to working with a Dremel tool to cut metal, safety should always be your top priority.

Before you start, it’s crucial to ensure that you have the right safety gear, and that your workspace is properly set up to minimize any potential risks. Let’s delve into the essential steps for preparing to cut metal with a Dremel.

Safety Gear And Precautions

Before beginning any metal-cutting project with a Dremel tool, it’s essential to gather the necessary safety gear to protect yourself from potential hazards.

Here are the key safety gear and precautions to consider:

- Wear safety goggles to shield your eyes from metal shards and debris.

- Put on a dust mask to prevent inhalation of metal dust and particles.

- Use heavy-duty gloves to protect your hands from sharp metal edges and heat.

- Wear ear protection to minimize exposure to the noise generated during cutting.

- Secure loose clothing and tie back long hair to avoid entanglement with the Dremel tool.

Setting Up Your Workspace

Creating a safe and organized workspace is crucial when preparing to cut metal with a Dremel tool. Follow these steps to set up your workspace:

- Choose a well-ventilated area to work in, preferably outdoors or in a well-ventilated workshop.

- Clear the work surface of any clutter or obstructions to ensure a stable and unobstructed workspace.

- Place the metal piece to be cut on a stable workbench or clamp it securely in place to prevent movement during cutting.

- Ensure that the Dremel tool is equipped with a cutting wheel suitable for metal, and that it is securely attached according to the manufacturer’s instructions.

- Double-check that the power source for the Dremel tool is easily accessible and that the tool’s cord is positioned to avoid tripping hazards.

Step-by-step Guide To Cutting Metal

Cutting metal with a Dremel can seem daunting, but with the right technique and tools, it can be a straightforward process.

Here’s a step-by-step guide to cutting metal with a Dremel, covering marking and measuring the metal, techniques for effective cutting, and safety considerations.

Marking And Measuring The Metal

Before cutting metal with a Dremel, it’s crucial to accurately mark and measure the area to be cut. Use a permanent marker to clearly outline the cutting path on the metal surface. Ensure that the measurements are precise to avoid any errors during the cutting process.

Techniques For Effective Cutting

When cutting metal with a Dremel, it’s essential to use the appropriate cutting disc for the specific type of metal. Reinforced fiberglass cutting discs are ideal for cutting through metal due to their durability and precision.

Additionally, it’s important to maintain a steady hand and apply consistent pressure to achieve a clean and precise cut.

Troubleshooting Common Issues

Cutting metal with a Dremel can lead to common issues. Ensure the metal is securely clamped and use the appropriate cutting wheel for best results. Troubleshoot issues like overheating by using the correct speed settings and cooling techniques.

Metal cutting with a Dremel tool can be challenging, especially if you encounter common issues such as overheating and rough edges. In this section, we will discuss some troubleshooting tips that will help you overcome these problems.

Dealing With Overheating

Overheating can damage your Dremel tool and affect the quality of your metal cutting. To prevent overheating, follow these tips:

- Use the right speed setting for the type of metal you are cutting. High speed can cause overheating, while low speed can result in poor cutting performance.

- Ensure that the cutting bit is clean and free from debris. A clogged bit can cause overheating.

- Take breaks when cutting for long periods. Overuse can cause the tool to overheat.

- Consider using a cooling system such as compressed air or water to keep the tool cool.

How To Manage Rough Edges

Rough edges can make your metal cutting look unprofessional and affect the final product’s quality. Here are some tips to manage rough edges:

- Use the right cutting bit for the type of metal you are cutting. A wrong bit can cause rough edges.

- Ensure that the cutting bit is sharp and in good condition. Dull bits can cause rough edges.

- Use a sanding bit to smooth out rough edges after cutting.

- Consider using a cutting lubricant such as oil to reduce friction and prevent rough edges.

In conclusion, cutting metal with a Dremel tool can be challenging, but with these troubleshooting tips, you can overcome common issues such as overheating and rough edges.

Remember to use the right cutting bit, take breaks when cutting for long periods, and keep your tool clean and in good condition.

Maintenance And Care For Your Dremel

Cleaning After Use

After using your Dremel for cutting metal, it is crucial to clean it thoroughly. Begin by unplugging the tool and using a soft brush to remove any metal shavings and dust from the body and vents.

Then, wipe the tool with a clean, dry cloth to ensure all debris is removed. This will prevent the accumulation of metal particles that could affect the tool’s performance and longevity.

Routine Maintenance Tips

Regular maintenance is essential for keeping your Dremel in top condition. Periodically lubricate the motor shaft and bearings with a small amount of oil to ensure smooth operation. Additionally, check the carbon brushes for wear and replace them if necessary.

Inspect the collet for any signs of damage, and clean it to remove any metal residue. Proper care will extend the life of your Dremel and ensure it remains effective for metal cutting tasks.

Advanced Projects And Ideas

For those looking to take their metalworking skills to the next level, advanced projects with a Dremel offer exciting possibilities.

Intricate Designs On Metal

Creating detailed patterns and designs on metal surfaces with a Dremel opens up a world of artistic expression.

Combining Metal With Other Materials

Explore the unique blend of metal with wood, glass, or plastic to craft innovative and visually stunning projects.

Frequently Asked Questions

Can A Dremel Tool Be Used To Cut Metal?

Yes, a Dremel tool can be used to cut metal. It is versatile and can handle various metal cutting tasks effectively.

Which Dremel Is Best For Cutting Metal?

The Dremel 4300 is best for cutting metal due to its powerful motor and versatile accessories. It offers precise and efficient metal cutting.

How To Put A Metal Cutter On A Dremel?

To put a metal cutter on a Dremel, insert the cutter into the collet and tighten securely. Use the provided wrench to secure it in place. Make sure it is properly aligned before tightening. Now, your Dremel is ready for metal cutting tasks.

Will A Dremel Grind Steel?

Yes, a Dremel can grind steel effectively due to its high-speed rotary tool capabilities.

Conclusion

Cutting metal with a Dremel can be a versatile and efficient solution. With the right attachments and techniques, you can achieve precise and clean cuts on various metal surfaces. Whether for DIY projects or professional tasks, a Dremel tool offers a handy tool for metal cutting needs.