Dewalt sockets are made in Taiwan and China. These high-quality tools are known for durability and reliability.

Dewalt’s commitment to excellence ensures that their sockets meet the highest standards in the industry. Whether you are a professional mechanic or a DIY enthusiast, Dewalt sockets are designed to withstand tough conditions and provide long-lasting performance.

The manufacturing process involves precision engineering and stringent quality control measures to deliver products that exceed customer expectations. With Dewalt sockets, you can trust that you are getting top-notch tools that will help you tackle any job with ease.

Contents

- Introduction To Dewalt Sockets

- History Of Dewalt

- Craftsmanship Behind Dewalt Sockets

- Global Footprint Of Dewalt Manufacturing

- The Debate On Manufacturing Locations

- Unraveling The Origins Of Dewalt Sockets

- Impact Of Origin On Tool Performance

- Future Of Dewalt’s Manufacturing

- Consumer Guide To Choosing Dewalt Sockets

- Frequently Asked Questions

- Conclusion

Introduction To Dewalt Sockets

Dewalt sockets are manufactured in the United States, specifically in their plants located in North and South Carolina. Dewalt’s commitment to quality and innovation is reflected in the production of their sockets domestically.

The Rise Of Dewalt In The Tool Industry

Dewalt is a well-established name in the tool industry, known for its high-quality products. The company’s reputation has been built on a commitment to innovation and durability.

Importance Of Manufacturing Origins

Where Dewalt sockets are made is a crucial aspect for consumers who prioritize quality and reliability. The manufacturing origins play a significant role in determining the overall quality of the product.

When it comes to Dewalt sockets, understanding where they are made provides valuable insights into the manufacturing standards and processes employed by the company.

This information is essential for consumers seeking products that meet their expectations for performance and longevity.

History Of Dewalt

Dewalt sockets are made in various global manufacturing facilities, including the USA, Mexico, China, and Taiwan. The brand’s history dates back to the 1920s, with a focus on producing high-quality tools and accessories.

Dewalt’s commitment to innovation and durability ensures top-notch products for professionals and DIY enthusiasts alike.

Founding And Early Years

Dewalt is a well-known brand that manufactures power tools and hand tools for construction, manufacturing, and woodworking industries. The company was founded in 1924 by Raymond E. Dewalt.

It started with the invention of the radial arm saw, which quickly gained popularity due to its efficiency and precision in woodworking. This marked the beginning of Dewalt’s legacy in the power tools industry.

Evolution Of Product Lines

Over the years, Dewalt has expanded its product lines to include a wide range of tools, including sockets, wrenches, and ratchets.

The company has continuously evolved its products to meet the changing needs of professionals and DIY enthusiasts. Dewalt’s commitment to innovation and quality has solidified its position as a leader in the power tools market.

Craftsmanship Behind Dewalt Sockets

Dewalt sockets are crafted using high-quality materials and innovative design techniques.

The sockets are made from durable chrome vanadium steel, ensuring longevity and reliability.

The design features precision-machined components for a perfect fit and maximum torque transfer.

Dewalt employs stringent quality control processes to ensure each socket meets high standards.

Every socket undergoes rigorous testing to guarantee accuracy and performance.

Each socket is inspected at multiple stages of production to maintain consistency and excellence.

Global Footprint Of Dewalt Manufacturing

Dewalt Sockets are manufactured in various locations worldwide, reflecting the brand’s global footprint. Production sites include the United States, Mexico, China, and other countries, ensuring high-quality tools for customers globally.

Dewalt is a well-known brand that produces high-quality tools and equipment for professionals and DIY enthusiasts. One of the most sought-after products of Dewalt is its sockets that are used in a variety of applications.

When it comes to the manufacturing of Dewalt sockets, people often wonder where they are made. Dewalt has a global footprint when it comes to manufacturing, with factories and international partnerships all over the world. In this blog post, we will explore the global footprint of Dewalt manufacturing and where its sockets are made.

Mapping Dewalt’s Factories

Dewalt has a vast network of factories all over the world. The company has manufacturing facilities in the United States, Mexico, Brazil, China, the Czech Republic, and Italy.

These factories produce a wide range of products, including sockets, power tools, hand tools, and accessories.

Dewalt’s factories are equipped with state-of-the-art technology and employ skilled workers who ensure that each product meets the company’s high-quality standards.

International Partnerships And Outsourcing

Apart from its factories, Dewalt also has several international partnerships that help the company expand its global reach. For instance, Dewalt has a partnership with Stanley Black & Decker, which allows it to access the company’s manufacturing facilities and distribution channels worldwide.

Dewalt also outsources some of its production to third-party manufacturers, mainly in Asia, to reduce costs and increase efficiency. Dewalt’s global footprint in manufacturing allows it to produce high-quality products at competitive prices.

The company’s factories and international partnerships ensure that its products are available to customers worldwide. When it comes to Dewalt sockets, they are made in several factories worldwide, ensuring that they are readily available to customers in different regions.

The Debate On Manufacturing Locations

Dewalt Sockets’ manufacturing location sparks debates among enthusiasts worldwide, with production sites in the USA, Mexico, China, and Taiwan. These differing locations influence quality perceptions and preferences among consumers.

Consumer Perceptions Of Quality

When it comes to tools, especially those used in heavy-duty industries, quality is a crucial factor that cannot be compromised. Consumers want to know where their tools are manufactured, and Dewalt sockets are no exception.

There is a common perception that products made in the United States have better quality and durability than those made elsewhere.

However, this is not necessarily true, and Dewalt has proven that they can produce high-quality sockets regardless of the manufacturing location.

Economic Implications Of Manufacturing Sites

The location of the manufacturing site can have a significant impact on the overall cost of the product.

Dewalt has manufacturing sites in various countries, including the United States, China, Taiwan, and Mexico. Each location has its advantages and disadvantages, and the choice of where to manufacture depends on several factors, including labor costs, raw material availability, and government regulations.

For instance, manufacturing in China is often more cost-effective due to the lower labor costs, while manufacturing in the United States may result in higher costs due to higher wages and stricter regulations.

However, manufacturing in the United States may appeal to consumers who are willing to pay a premium for American-made products, even if the quality is the same as those made elsewhere.

In conclusion, the location of manufacturing sites for Dewalt sockets is a subject of debate. While consumers may have their preferences, the quality of the sockets is not necessarily determined by the manufacturing location.

Dewalt has proven that they can produce high-quality sockets regardless of the manufacturing site. Ultimately, the choice of where to manufacture depends on several factors, including economic implications and government regulations.

Unraveling The Origins Of Dewalt Sockets

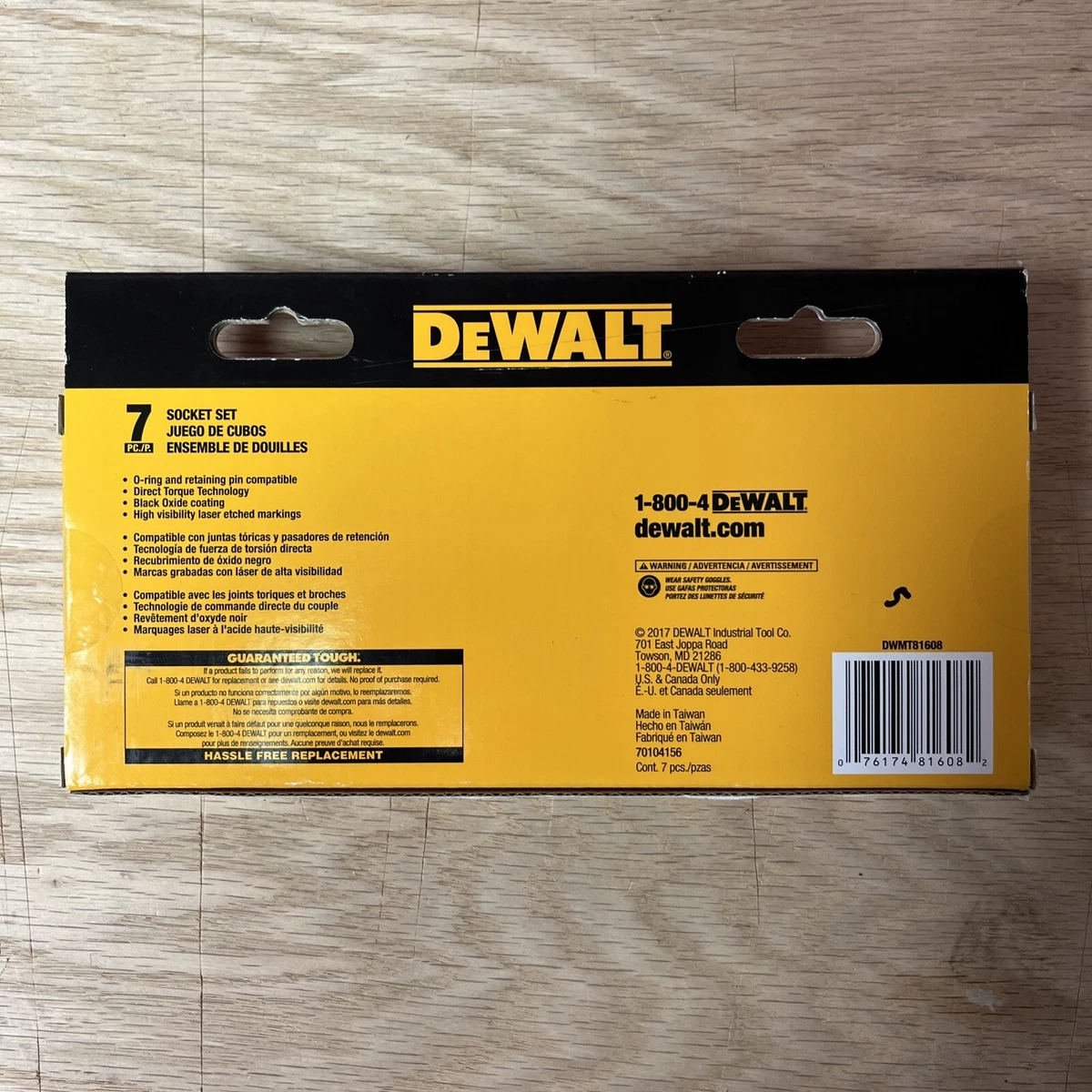

Dewalt sockets are proudly made in Taiwan, with a commitment to quality and durability. The origins of Dewalt sockets lie in the meticulous manufacturing process and stringent quality control measures implemented in Taiwan. This ensures that Dewalt sockets meet the high standards expected by professionals and DIY enthusiasts alike.

Tracing The Supply Chain

Dewalt sockets are renowned for their quality and durability. Let’s dive into where these essential tools are made.

Current Manufacturing Hubs For Dewalt Sockets

Impact Of Origin On Tool Performance

The origin of Dewalt sockets plays a significant role in their performance. Dewalt sockets are made in various countries, including the United States, China, and Taiwan. The manufacturing location can impact the quality and durability of the sockets, influencing their overall performance and reliability in different working conditions.

Impact of Origin on Tool Performance Material sourcing and tool durability The country of origin for tools, such as Dewalt sockets, often impacts the material sourcing and ultimately the durability of the tools.

When the sockets are manufactured in countries with stringent quality control measures, the materials sourced are generally of higher quality, resulting in more durable and long-lasting tools. This can directly impact the performance and reliability of the sockets in real-world usage.

The correlation between origin and reliability The correlation between the origin of tools and their reliability is a crucial factor to consider when selecting tools for professional or personal use. Tools manufactured in countries known for their expertise in engineering and production processes often exhibit higher reliability and consistency in performance.

This correlation is particularly evident in the case of Dewalt sockets, where the origin can significantly influence the overall reliability and durability of the tools. For instance, Dewalt sockets manufactured in countries with a strong tradition of precision engineering and quality control are more likely to exhibit superior reliability and performance.

On the other hand, tools produced in regions with less stringent regulations and quality standards may have a higher likelihood of performance issues and shorter lifespans.

By understanding the impact of origin on tool performance, users can make informed decisions when selecting sockets and other tools for their professional or personal needs.

The origin of a tool is not just a matter of geographic location, but a key factor that can directly influence the reliability, durability, and overall performance of the tool in real-world applications.

Future Of Dewalt’s Manufacturing

The future of Dewalt’s manufacturing is marked by innovations in production and shifting trends in global manufacturing. Dewalt, a renowned brand in the power tools industry, has been a symbol of quality and reliability for decades.

As the demand for its products continues to grow globally, the company is exploring new avenues to enhance its manufacturing processes and meet the evolving needs of the market.

Innovations In Production

Dewalt has been at the forefront of embracing cutting-edge technologies to enhance its production processes. The integration of advanced machinery and automation has not only improved the efficiency of manufacturing but also ensured consistent quality across its range of products.

The company’s commitment to innovation has resulted in the development of smart manufacturing solutions that optimize resource utilization and minimize wastage.

Shifting Trends In Global Manufacturing

The global manufacturing landscape is undergoing significant changes, with a growing emphasis on sustainability and ethical practices.

Dewalt is cognizant of these trends and has been strategically realigning its manufacturing operations to align with these evolving industry standards.

The company’s investment in eco-friendly manufacturing processes and materials underscores its dedication to sustainability.

Consumer Guide To Choosing Dewalt Sockets

What To Look For In A Socket Set

When selecting a socket set, it’s essential to consider the specific needs of your projects. Look for durable materials such as chrome vanadium steel, which ensures longevity and reliability. Opt for sets that include a variety of sizes to accommodate diverse fasteners.

How To Verify The Authenticity Of Dewalt Products

Ensuring the authenticity of Dewalt products is crucial. Always purchase from authorized dealers or directly from the manufacturer’s website. Check for the Dewalt logo, packaging, and serial numbers to confirm the product’s legitimacy.

Frequently Asked Questions

Is Dewalt Made In China Or USA?

DeWalt tools are manufactured in both China and the USA. Some products are made in China, while others are made in the USA.

Who Makes Dewalt Socket Sets?

DeWalt socket sets are made by Stanley Black & Decker, a global diversified industrial company.

Is Dewalt A Good Socket Brand?

Yes, DeWalt is a good socket brand. They offer high-quality sockets that are durable and long-lasting.

DeWalt sockets are known for their precision and strength, making them a reliable choice for both professionals and DIY enthusiasts.

Are Dewalt Bits Made In China?

Yes, some DeWalt bits are made in China. DeWalt has manufacturing facilities in several countries, including China, where they produce a portion of their products.

However, DeWalt maintains strict quality control standards to ensure that their products meet their high-quality standards, regardless of where they are manufactured.

Conclusion

Dewalt sockets are proudly manufactured in the United States. The company’s commitment to quality and durability is reflected in their American-made products.

By choosing Dewalt sockets, you are not just investing in a tool, but in American craftsmanship and reliability. Choose Dewalt for trusted quality.