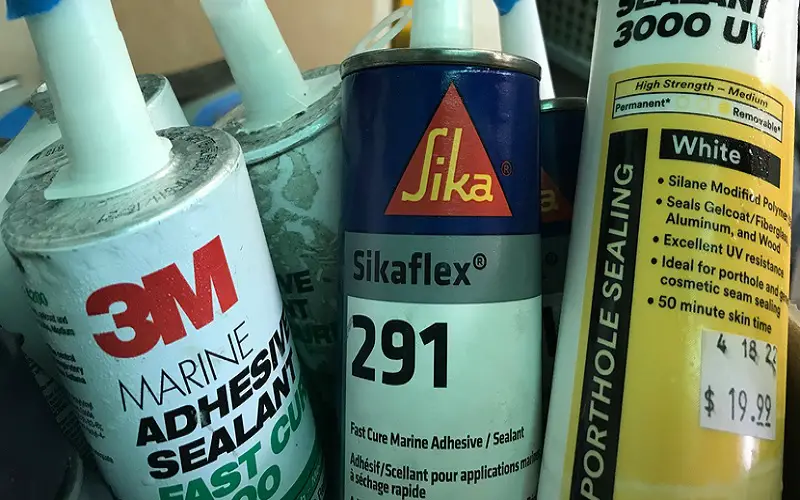

Sikaflex 291 and 3M 4200 are two popular adhesive sealants used in various applications. While Sikaflex 291 is known for its strong bonding capabilities and resistance to UV rays, 3M 4200 offers excellent adhesion and flexibility.

Now, let’s dive into more details about these two products. Sikaflex 291 is a marine-grade adhesive sealant that is widely used in boat building and repair. It is known for its excellent bonding strength, weather resistance, and durability.

This product can be used above and below the waterline, making it suitable for a wide range of applications in the marine industry. Additionally, Sikaflex 291 is UV-resistant, ensuring that it can withstand prolonged exposure to sunlight without deteriorating.

On the other hand, 3M 4200 is another popular adhesive sealant used in various industries, including marine, automotive, and construction. It offers excellent adhesion and flexibility, making it a preferred choice for applications that require a strong bond that can also withstand movement and vibration.

Furthermore, 3M 4200 is resistant to saltwater, making it suitable for marine applications. While both Sikaflex 291 and 3M 4200 are reliable adhesive sealants, their key differences lie in their specific features and applications. By understanding the unique qualities of each product, you can choose the one that best suits your needs.

Contents

Sikaflex 291

If you’re in the market for marine sealants, Sikaflex 291 is definitely a product worth considering. With its exceptional adhesive properties and resistance to water, Sikaflex 291 is a popular choice among boat owners and DIY enthusiasts alike.

Let’s take a closer look at its features, applications, as well as its pros and cons.

Features

Sikaflex 291 boasts a range of features that make it a standout marine sealant. These include:

- Impressive bonding strength

- Excellent resistance to weathering and seawater

- Highly elastic, allowing for joint movement without compromising adhesion

- Fast curing time, enabling quick project completion

Applications

Due to its versatile nature, Sikaflex 291 can be used in various marine applications, such as:

- Sealing of joints and seams in boat hulls

- Bonding of deck hardware and fittings

- General maintenance and repair work on vessels

- Adhering of substrates in marine construction projects

Pros And Cons

Pros:

- Excellent bonding strength

- Resistance to harsh marine environments

- Quick curing time for efficient project completion

Cons:

- May require additional surface preparation for optimal adhesion

- Can be challenging to remove once cured

3m 4200

Now, let’s delve into the notable features, applications, and the pros and cons of 3M 4200, a widely used marine adhesive and sealant.

Features

Flexibility: 3M 4200 offers excellent flexibility, allowing it to withstand vibrations, movements, and shocks, making it suitable for marine and automotive applications.

Adhesion: The adhesive properties of 3M 4200 make it highly effective for bonding a wide range of materials, including metals, fiberglass, and wood.

Water resistance: With impressive water resistance capabilities, this sealant is perfect for applications exposed to moisture and harsh maritime environments.

Applications

The versatility of 3M 4200 makes it an ideal choice for various applications, including but not limited to:

- Deck fittings

- Hull seams

- Through-hull fittings

- Wooden and fiberglass boat constructions

- Sealing and bonding applications in automotive settings

Pros And Cons

Pros:

- Excellent flexibility and adhesion

- Outstanding water resistance

- Versatile applications

Cons:

- Long cure time

- May not be suitable for all plastics

Key Differences

Curing Time

Sikaflex 291 cures faster than 3M 4200, taking about 24 hours to fully set, while 3M 4200 needs approximately 48 hours to reach full cure.

Adhesion Strength

Sikaflex 291 offers greater adhesion strength compared to 3M 4200, especially on a wide range of materials including metals, fiberglass, and wood.

Flexibility

3M 4200 is more flexible than Sikaflex 291, making it ideal for applications where movement or vibration is a concern, ensuring durability over time.

Suitable Applications

When considering suitable applications, Sikaflex 291 is well-suited for marine sealing, bonding, and general purpose sealing, while 3M 4200 is preferred for marine above-the-waterline applications.

Best Practices

When comparing Sikaflex 291 and 3M 4200, it’s important to consider their best practices for various applications.

Both products offer high-quality adhesion and sealing properties, but Sikaflex 291 is favored for its excellent UV resistance, while 3M 4200 is known for its exceptional flexibility and durability.

Surface Preparation

Before using either Sikaflex 291 or 3M 4200, it is crucial to properly prepare the surface to ensure optimal adhesion and long-lasting results.

Follow these best practices for surface preparation:

| Surface Preparation Steps | Sikaflex 291 | 3M 4200 |

|---|---|---|

| 1. Clean the surface | Use a solvent such as acetone to remove dirt, rust, grease, and other contaminants. | Wipe the surface clean using a clean cloth and ensure it is free from any dirt or debris. |

| 2. Dry the surface | Allow the surface to dry completely before applying Sikaflex 291. | Ensure the surface is dry and free from any moisture before applying 3M 4200. |

| 3. Roughen the surface | Using sandpaper or a wire brush, gently roughen the surface to create a better bond. | To improve adhesion, lightly sand the surface with fine-grit sandpaper. |

Application Techniques

Proper application techniques are essential for achieving the best results with Sikaflex 291 or 3M 4200.

- Apply a bead of sealant in a continuous motion, ensuring full coverage of the joint or seam.

- Smooth the sealant using a sealant tool or a moistened finger within the recommended application time.

- Remove any excess sealant using a clean rag or paper towel.

- Allow the sealant to cure undisturbed for the specified time period.

By following these best practices for surface preparation and application techniques, you can maximize the performance and longevity of your sealant.

Cost Comparison

Comparing the costs of Sikaflex 291 and 3M 4200 can help you make an informed decision. Both products offer reliable performance, but examining their prices can assist you in choosing the best option for your needs.

By conducting a cost analysis, you can determine which product provides the greatest value for your investment. When choosing between Sikaflex 291 and 3M 4200 sealants, cost is an important factor to consider.

Understanding the initial cost and long-term durability of these products can help make an informed decision. Let’s compare the costs of Sikaflex 291 and 3M 4200 to determine which option provides better value for your needs.

Initial Cost

When it comes to the initial cost, Sikaflex 291 and 3M 4200 differ slightly. Sikaflex 291 tends to be more cost-effective, offering a budget-friendly option for those looking to save on their project expenses.

On the other hand, 3M 4200 might be slightly pricier, but it also brings added benefits that might justify the extra cost.

Long-term Durability

Durability is a crucial consideration when evaluating sealants. Both Sikaflex 291 and 3M 4200 are known for their ability to form strong adhesive bonds and provide excellent resistance to various environmental conditions.

- Sikaflex 291 is a marine-grade sealant, specifically designed to withstand exposure to saltwater, UV rays, and harsh weather conditions. Its long-lasting formula ensures that your project remains protected for years to come.

- 3M 4200, on the other hand, offers impressive durability and maintains its strength even in high-stress environments. Its unique chemistry allows it to resist vibrations, impact, and extreme temperatures, making it suitable for a wide range of applications.

Both sealants offer long-term durability, but their specific strengths differ based on the nature of your project.

When considering the cost comparison between Sikaflex 291 and 3M 4200, it’s essential to weigh both the initial cost and long-term durability.

Sikaflex 291 may be a more cost-effective option, while 3M 4200 brings added benefits that might justify its slightly higher price. Consider the specific requirements of your project to choose the sealant that offers the best value in terms of cost and long-term performance.

User Experiences

When choosing between Sikaflex 291 and 3M 4200, user experiences play a vital role in determining the right adhesive sealant for your project.

Let’s delve into the feedback on these two popular products to help you make an informed decision.

Feedback On Sikaflex 291

Waterproof: Sikaflex 291 receives praise for its excellent waterproofing properties, ensuring a reliable seal even in harsh marine environments.

Strong Adhesion: Users appreciate the high bonding strength of Sikaflex 291, which adheres effectively to various surfaces, providing long-lasting results.

Easy Application: The smooth application of Sikaflex 291 makes it convenient for both professionals and DIY enthusiasts, saving time and effort.

Feedback On 3m 4200

Versatile Usage: Users find 3M 4200 versatile for a wide range of applications, from sealing joints in boats to bonding metal surfaces.

Flexibility: 3M 4200 offers flexibility that allows for natural movements of materials without compromising the seal, a crucial feature for dynamic environments.

Durability: The long-lasting durability of 3M 4200 impresses users, ensuring a reliable bond that withstands various environmental conditions.

Frequently Asked Questions Of Sikaflex 291 Vs 3m 4200

What Is Equivalent To Sikaflex 291?

An equivalent to Sikaflex 291 is 3M 5200 sealant. It provides strong, flexible bonding, ideal for marine applications.

What Is Sikaflex 291 Used For?

Sikaflex 291 is used as a multipurpose marine sealant. It is ideal for above and below waterline applications, such as bonding and sealing of joints.

Its strong adhesive properties make it suitable for various materials, including wood, metal, and fiberglass, providing a durable and waterproof seal.

Which Sikaflex Is Strongest?

The strongest Sikaflex is the Sikaflex 292i, known for its high strength and durability. It is specially formulated to withstand extreme conditions and has excellent adhesion properties.

What Is The Difference Between Sikaflex 291 And 291i?

Sikaflex 291 has higher viscosity for sealing joints, while Sikaflex 291i is more flexible for bonding applications.

Conclusion

Our comparison of Sikaflex 291 vs 3M 4200 shows both are top choices for sealants and adhesives. Depending on your project needs, each has unique qualities to consider.

With this information, you can make an informed decision for your marine, automotive, or construction applications.