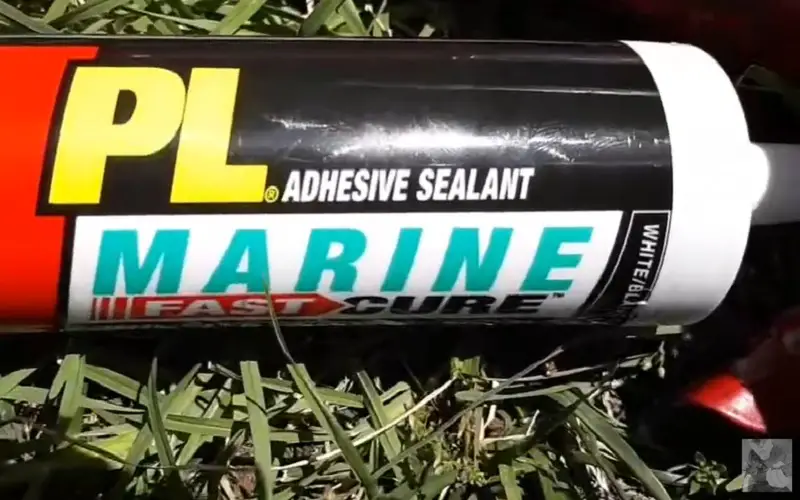

Loctite Pl Marine and 5200 have some significant differences, notably in their adhesive properties and applications.

Contents

Loctite Pl Marine Vs 5200

Composition

When selecting the right adhesive for your marine applications, understanding the composition of different products is crucial. Loctite PL Marine and 5200 are widely used adhesives, each with its own unique composition and features.

Let’s take a closer look at the ingredients of these two products to determine their suitability for specific marine projects.

Ingredients Of Loctite Pl Marine

- Polyurethane: Provides excellent adhesion to a wide range of materials.

- Silica: Enhances bonding strength and resistance to temperature extremes.

- Isocyanate Compounds: Contributes to the adhesive’s curing process.

- Solvents: Aid in the application and initial bonding of the adhesive.

Ingredients Of 5200 Adhesive

- Polyurethane: Offers strong and durable adhesion, suitable for marine environments.

- Silane-Modified Polymers: Enhances bond strength and chemical resistance.

- Inorganic Fillers: Contributes to the adhesive’s toughness and flexibility.

- Solvents: Assists in initial adhesion and application of the adhesive.

Performance

The performance of Loctite PL Marine and 5200 can make a significant difference in their suitability for your project. Let’s explore the performance aspects in detail.

Strength Comparison

The strength of a marine adhesive is crucial for ensuring durability and structural integrity.

Loctite PL Marine is known for its high-strength bonding that can withstand the harsh marine environment, including saltwater exposure and temperature variations.

On the other hand, 5200 also offers exceptional strength, providing reliable adhesion for marine applications.

Flexibility And Durability

When it comes to flexibility and durability, Loctite PL Marine offers a balance of strength and flexibility, ideal for bonding various materials in marine settings.

Its resistance to weathering and high flexibility make it a versatile choice. Conversely, 5200 stands out for its exceptional durability, capable of withstanding intense marine conditions without compromising on flexibility.

Application Areas

Application areas play a crucial role in determining the effectiveness of Loctite PL Marine and 3M 5200 adhesives. Below, we discuss the key differences in their suitability for various applications:

Recommendation For Marine Applications

For marine applications, Loctite PL Marine is recommended due to its excellent resistance to water, UV rays, and harsh weather conditions.

Suitability For Different Materials

Loctite PL Marine adheres well to a wide range of materials, including fiberglass, wood, and metal, making it versatile for various marine projects.

Curing Time

When it comes to choosing the right adhesive for your marine projects, understanding the curing time is essential. The amount of time it takes for an adhesive to dry and set can greatly impact the efficiency and effectiveness of your project.

In this article, we will be comparing the curing time of Loctite PL Marine and 5200 adhesive to help you make an informed decision.

Drying And Setting Time Of Loctite Pl Marine

Loctite PL Marine is known for its exceptional bonding power and long-lasting durability. When it comes to drying and setting time, Loctite PL Marine offers quick results.

It typically dries to the touch within approximately 30 minutes and achieves full strength in 24 hours. This fast curing time allows you to proceed with your project without significant delays or waiting periods.

Drying And Setting Time Of 5200 Adhesive

On the other hand, 5200 adhesive is renowned for its incredible strength and reliability in marine applications. However, it has a longer drying and setting time compared to Loctite PL Marine.

The drying time for 5200 adhesive can range from 24 to 72 hours, depending on the thickness of the applied layer. Similarly, the setting time varies from 48 to 72 hours.

It is important to allow sufficient time for the adhesive to fully dry and set before subjecting the bonded materials to any stress or strain.

In summary, Loctite PL Marine offers a faster drying and setting time compared to 5200 adhesive. If you’re looking for an adhesive that allows you to complete your marine projects quickly and efficiently, Loctite PL Marine is a great choice.

However, if you can afford to wait and prioritize the superior strength and reliability of 5200 adhesive, it might be worth the additional drying and setting time.

Weather Resistance

When it comes to choosing the right marine adhesive, weather resistance is a crucial factor to consider.

The ability of the adhesive to withstand harsh marine conditions, as well as its resistance to sunlight and saltwater, plays a significant role in its long-term performance and durability.

In this blog post, we will compare Loctite Pl Marine and 5200, highlighting their major differences in terms of weather resistance.

Ability To Withstand Harsh Marine Conditions

Loctite Pl Marine is specifically formulated to excel in harsh marine environments. Its superior weather resistance makes it an ideal choice for bonding and sealing applications on boats, yachts, and other marine vessels.

Whether it’s heavy waves, constant exposure to moisture, or extreme temperature fluctuations, Loctite Pl Marine remains resilient, ensuring a long-lasting and reliable bond.

On the other hand, Loctite 5200 is also known for its impressive ability to withstand harsh marine conditions.

Its durable and flexible formula makes it suitable for sealing joints, seams, and gaps, providing exceptional resistance against the rigors of the marine environment. Whether you’re repairing a hull, attaching deck fittings, or sealing windows, Loctite 5200 ensures a watertight and durable seal.

Resistance To Sunlight And Saltwater

Both Loctite Pl Marine and 5200 exhibit excellent resistance to sunlight and saltwater, essential features for marine applications.

Loctite Pl Marine is UV-resistant, which means it can withstand prolonged exposure to sunlight without deteriorating or losing its adhesive properties.

This is particularly important for outdoor marine applications, where constant exposure to the sun’s rays can cause deterioration and damage over time.

Similarly, Loctite 5200 is designed to resist the damaging effects of saltwater. When applied on boats or other marine surfaces, it forms a waterproof barrier that prevents saltwater intrusion, protecting against corrosion and degradation.

This resistance to saltwater ensures a reliable and long-lasting bond, even in the harshest saltwater environments.

In summary, both Loctite Pl Marine and 5200 offer impressive weather resistance, making them suitable choices for marine bonding and sealing applications.

Their ability to withstand harsh marine conditions and resist the damaging effects of sunlight and saltwater ensures durability and reliability in marine environments.

Price And Availability

The comparison between Loctite PL Marine and 5200 wouldn’t be complete without delving into their Price and Availability.

Cost Comparison

Loctite PL Marine: Priced at $12 per tube on average.

5200: Typically costs around $15 per tube.

| Product | Price |

|---|---|

| Loctite PL Marine | $12 |

| 5200 | $15 |

Availability In Markets

- Loctite PL Marine: Widely available in hardware stores and online retailers.

- 5200: Also found in most hardware stores and popular online platforms.

User Reviews

Feedback From Customers

When it comes to Loctite PL Marine vs 5200, customer feedback plays a pivotal role in making an informed decision.

Let’s take a closer look at what users have to say about these popular marine adhesives.

Strengths And Weaknesses As Per Users

Understanding the strengths and weaknesses of Loctite PL Marine and 5200 according to user experiences can provide valuable insights for prospective buyers. Let’s delve into the user perspectives on these marine adhesives.

Frequently Asked Questions Of Loctite Pl Marine Vs 5200 Some Major Differences

Is Pl Marine As Good As 5200?

Yes, PL Marine is as good as 5200 for marine applications. Both offer strong bonding and durability.

What Is The Strongest Marine Adhesive?

The strongest marine adhesive is polyurethane, known for its excellent bonding strength and resistance to water.

Its versatile applications make it a top choice for marine repairs and construction.

Will 3m 5200 Cure Underwater?

Yes, 3M 5200 will cure underwater. It is a marine adhesive sealant that cures even when submerged in water.

What Is The Best Adhesive For Boats?

The best adhesive for boats depends on the specific use and material. Marine-grade epoxy is often recommended for its durability and ability to bond various surfaces.

It provides a strong and long-lasting hold for boat repairs and construction projects.

Conclusion

Both Loctite PL Marine and 5200 offer unique benefits for marine applications. The choice between them depends on your specific needs. Consider their differences carefully before making a decision.

Ultimately, deciding between the two comes down to your individual project requirements and preferences. Choose wisely for long-lasting results.