Views: 34

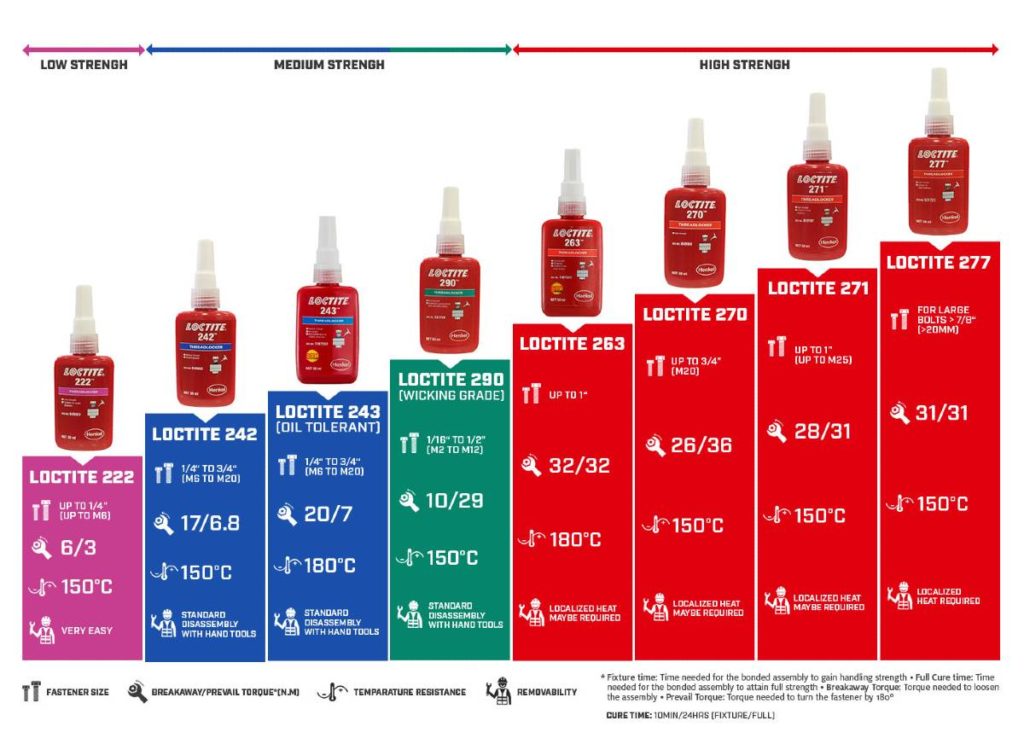

Loctite 270 is a high-strength threadlocker designed for permanent locking and sealing of threaded fasteners, while Loctite 271 is a medium-strength threadlocker used for locking and sealing fasteners that require disassembly with standard hand tools. Loctite 270 is a permanent locking threadlocker, providing extremely strong bonding.

On the other hand, Loctite 271 is a removable threadlocker, allowing for easier disassembly of fasteners. When choosing between Loctite 270 and 271, it is important to consider the specific needs of your project. If you require a strong, permanent bond that cannot be easily removed, Loctite 270 is the ideal choice.

However, if you need the flexibility to remove fasteners in the future, Loctite 271 is the better option. Both products offer excellent threadlocking and sealing capabilities, ensuring secure and reliable performance in various applications.

Contents

Loctite 270 Vs Loctite 271

Composition

When it comes to the composition of Loctite 270 and Loctite 271, understanding their ingredients can provide valuable insights into their applications and performance.

Ingredients Of Loctite 270

- Methyl methacrylate

- Polyalkyl methacrylate

- Hydroxyalkyl methacrylate

Ingredients Of Loctite 271

- Methacrylated-functionalized dimethacrylate

- Hydroxy alkyl methacrylate

- Dimethacrylate ester

Strength

When considering the strength of threadlockers, precision in making a choice is vital. The comparison between Loctite 270 and 271, particularly focusing on strength, will help in deciding which one suits your needs best.

Comparing Strength Of Loctite 270

Loctite 270, known for its exceptional strength, is designed for securing cylindrical parts. It delivers high performance, especially in heavy-duty applications where resistance to heavy shock, vibration, and thermal cycling is crucial.

Comparing Strength Of Loctite 271

On the other hand, Loctite 271 also offers impressive strength, making it ideal for applications that require robust, reliable threadlocking. With its high-strength formula, Loctite 271 is particularly effective in preventing loosening due to impact and vibration.

Curing Time

The curing time of Loctite 270 and 271 is crucial for understanding their effectiveness in bonding applications. Let’s delve into the curing time for each of these high-quality threadlockers:

Curing Time For Loctite 270

- Loctite 270 has a fast curing time of approximately 10 minutes, providing quick and reliable bonding solutions.

- This rapid cure time makes Loctite 270 ideal for applications that require swift assembly and minimal downtime.

Curing Time For Loctite 271

- On the other hand, Loctite 271 offers a slightly longer curing time compared to Loctite 270, typically taking around 24 hours to fully cure.

- This extended cure time of Loctite 271 ensures deep and thorough bonding in critical applications.

Applications

When it comes to choosing the right adhesive for your projects, Loctite 270 and Loctite 271 are two popular options to consider. While both adhesives offer high strength and excellent bond characteristics, understanding their best applications is crucial to ensure optimal results.

In this article, we will explore the best applications for both Loctite 270 and Loctite 271, helping you make an informed decision for your specific needs.

Best Applications For Loctite 270

Loctite 270 is a high-strength threadlocker adhesive that is specifically designed for locking and sealing threaded fasteners. Its superior performance makes it an ideal choice for applications where heavy-duty bonding is required.

Some of the best applications for Loctite 270 include:

- Preventing loosening and securing of bolts, nuts, and studs in applications that are subject to vibration, shock, or heavy loads.

- Securing fasteners in automotive, machinery, and equipment assemblies to prevent leaks, corrosion, and loosening due to inherent vibration.

- Sealing and locking hydraulic and pneumatic fittings to prevent leaks and ensure reliable performance under high-pressure conditions.

With its exceptional strength and resistance to vibration, Loctite 270 offers reliable and long-lasting results in these demanding applications.

Best Applications For Loctite 271

Loctite 271 is another high-strength threadlocker adhesive that is specifically formulated for the locking and sealing of threaded assemblies. It offers similar characteristics to Loctite 270, but with added resistance to higher temperatures.

The best applications for Loctite 271 are:

- Securing and sealing fasteners in high-temperature environments, such as exhaust systems, combustion engines, and industrial equipment.

- Locking and securing threaded assemblies in outdoor applications exposed to extreme temperatures and weather conditions.

- Preventing loosening and corrosion of threaded connections in equipment and machinery used in harsh environments, including chemical processing and maritime industries.

With its ability to withstand higher temperatures, Loctite 271 is the go-to adhesive for applications requiring excellent bond strength in extreme conditions.

Temperature Resistance

Loctite 270 and 271 exhibit exceptional temperature resistance, making them ideal for demanding applications.

Both products possess high strength bonding capabilities with the key distinction being that Loctite 271 offers better resistance to temperature and oil. This makes it a superior choice for assemblies subjected to harsh conditions.

Temperature Resistance

When it comes to choosing a threadlocker adhesive for high-temperature applications, two popular options are Loctite 270 and Loctite 271.

These adhesives are known for their strength and durability, but how do they perform under high temperatures? Let’s take a closer look at how each one fares when subjected to heat.

How Loctite 270 performs under high temperatures?

Loctite 270 is a powerful adhesive that is designed to withstand extreme temperatures. With a temperature resistance of up to 232 degrees Celsius (450 degrees Fahrenheit), it is a reliable choice for applications where heat is a factor.

Whether you’re working on automotive engines, industrial machinery, or any other high-temperature environment, Loctite 270 can provide the strength and stability you need.

One of the key features of Loctite 270 is its ability to remain stable and reliable even when exposed to intense heat. It is specifically formulated to prevent the loosening or leaking of threaded fasteners, ensuring that they stay securely in place.

This makes it an ideal choice for applications where vibration, expansion, and contraction may occur due to temperature fluctuations. With Loctite 270, you can have peace of mind knowing that your fasteners will stay tight and secure, regardless of the heat they are subjected to.

In addition to its impressive temperature resistance, Loctite 270 also offers excellent chemical resistance, making it suitable for use in a variety of harsh environments.

Whether you’re dealing with oils, fuels, acids, or solvents, this adhesive can stand up to the challenge. Its robust formula ensures long-lasting performance, even in the face of extreme conditions.

How Loctite 271 performs under high temperatures

Similar to Loctite 270, Loctite 271 is known for its exceptional temperature resistance. It can withstand temperatures of up to 232 degrees Celsius (450 degrees Fahrenheit), making it a reliable choice for high-temperature applications.

Whether you’re working in the automotive, aerospace, or manufacturing industry, Loctite 271 can ensure that your fasteners remain tight and secure, even under extreme heat.

Loctite 271 is designed to provide a strong, reliable bond that can withstand vibration, impact, and temperature fluctuations. Its high-temperature resistance ensures that it remains effective, even in demanding environments.

This adhesive is ideal for applications where high temperatures are a concern, such as engine components, exhaust systems, or industrial equipment.

In addition to its temperature resistance, Loctite 271 also offers excellent chemical resistance, allowing it to withstand exposure to various fluids and solvents. Its versatility and durability make it a go-to choice for professionals who require a reliable adhesive for their high-temperature projects.

When it comes to temperature resistance, both Loctite 270 and Loctite 271 are excellent options. They can withstand extreme temperatures and provide a strong, reliable bond. Whether you choose Loctite 270 or Loctite 271 depends on the specific requirements of your project.

Consider factors such as the nature of the materials, the level of heat exposure, and the overall application to make an informed decision. With either adhesive, you can rest assured that your fasteners will remain secure, even in high-temperature environments.

Removability

Ease Of Removing Loctite 270

Loctite 270, being a high-strength threadlocker, is quite challenging to remove. It requires heat and a significant amount of effort.

Ease Of Removing Loctite 271

On the other hand, Loctite 271 is also a high-strength formula that can be challenging to remove, typically requiring heat for disassembly.

Recommendations

When deciding between Loctite 270 and Loctite 271, it’s important to understand recommendations for their usage in order to achieve optimal results.

Here’s a closer look at when to use each adhesive:

When To Use Loctite 270 Over Loctite 271

Loctite 270 is a high-strength adhesive designed for use on studs, bolts, and large fasteners that require a robust bond. It is specifically formulated for applications where disassembly is infrequent, making it ideal for securing components that are not intended to be removed often.

Consider using Loctite 270 in situations where the components will be subjected to heavy loads or harsh conditions, as it provides exceptional resistance to shock, vibration, and environmental factors.

When To Use Loctite 271 Over Loctite 270

Loctite 271, on the other hand, is best suited for smaller fasteners such as nuts, bolts, and screws that need a reliable seal and can be disassembled with hand tools.

This medium-strength adhesive is ideal for fasteners that may need to be removed for maintenance or repair, as it offers a strong bond while still allowing for disassembly without the need for special tools.

Consider using Loctite 271 in applications where accessibility for future servicing is crucial, as it provides a secure yet easily removable bond.

Frequently Asked Questions On Loctite 270 Vs 271

What Is Loctite 270 Used For?

LOCTITE 270 is used to secure cylindrical parts, such as bearings and shafts, by filling the inner voids for a solid bond. It prevents loosening due to vibration and temperature variation, ensuring a reliable and lasting connection.

Is Loctite 270 Permanent?

Yes, LOCTITE 270 is a permanent threadlocker that provides strong, lasting bond for metal surfaces. It is designed for use in heavy-duty applications where high strength and resistance to harsh environments are required.

What Is The Difference Between Loctite 2701 And Loctite 270?

Loctite 2701 and Loctite 270 are different types of adhesives. Loctite 2701 is a threadlocker adhesive designed for fasteners with small threads, while Loctite 270 is suitable for larger threaded fasteners. The main difference lies in their applications for different sizes of threads.

What Is The Difference Between Loctite 270 And Loctite 263?

LOCTITE 270 is for permanent threadlocking, while Loctite 263 is high-strength threadlocker for pre-assembled bolts.

Conclusion

Both Loctite 270 and 271 have unique properties for securing fasteners. Understanding their differences can help you choose the right one for your specific needs.

Whether it’s strength or flexibility, selecting the appropriate adhesive will ensure a secure and reliable bond for all your projects.