Yes, Super Glue is heat resistant and can withstand temperatures up to 180°F (82°C). It is commonly used for bonding heat-sensitive materials.

Super Glue is a type of adhesive that is known for its ability to withstand high temperatures, making it suitable for a wide range of applications. Whether you need to bond materials in high-temperature environments or require a reliable adhesive for heat-resistant projects, Super Glue is a versatile option.

Its heat-resistant properties make it an ideal choice for various crafting, repair, and industrial applications. With its ability to maintain its strength and durability under heat, Super Glue is a valuable adhesive for a diverse array of projects.

Contents

Introduction To Super Glue

Super glue, also known as cyanoacrylate adhesive, is a powerful and fast-acting adhesive that has become a staple in households and industries alike.

With its ability to bond a wide range of materials quickly, it has gained popularity for various purposes. In this blog post, we will explore the history of super glue, its common uses today, and whether it is heat resistant.

Brief History

The origins of super glue can be traced back to the 1940s when it was initially discovered by Dr. Harry Coover, a chemist working for Eastman Kodak. However, its adhesive properties were not immediately recognized, and it was only in the 1950s that its potential was realized.

Initially, super glue was developed as a clear plastic used for gun sights during World War II. However, it was deemed too sticky for that purpose and was set aside. It was not until years later that Dr. Coover noticed its incredible bonding ability while working on a heat-resistant jet canopy.

Dr. Coover and his team realized the commercial potential of this adhesive and patented it in 1958. The product was introduced to the market under the name “Eastman 910,” and it quickly gained popularity due to its exceptional bonding strength and quick-drying nature.

Common Uses Today

Super glue has come a long way since its discovery and is now widely used in various applications. Its versatility and reliability make it a go-to adhesive for many individuals and industries.

Here are some common uses of super glue today:

- Household Repairs: Super glue is often used to fix broken items around the house, such as ceramics, glass, plastic, and wood.

- Crafts and DIY Projects: It is a popular adhesive choice for crafters and DIY enthusiasts due to its quick bonding time and ability to adhere to different materials.

- Medical Applications: In the medical field, super glue is sometimes used to close small wounds or surgical incisions, acting as a substitute for traditional sutures.

- Electronics and Manufacturing: Super glue is commonly used in electronics assembly and manufacturing processes to bond small components and secure delicate parts.

- Automotive Repairs: It can be used to fix interior components, such as cracked dashboards or loose trim pieces, in automobiles.

These are just a few examples of how super glue is utilized in various industries and everyday life.

Chemical Composition Of Super Glue

The chemical composition of super glue plays a crucial role in its heat resistance and bonding capabilities. Super glue, also known as cyanoacrylate adhesive, is a type of fast-acting adhesive that forms strong bonds between materials.

Understanding the key ingredients and how it bonds materials can provide insight into the effectiveness of super glue in various applications.

Key Ingredients

Super glue primarily consists of cyanoacrylate monomers, which are the main active ingredients responsible for its adhesive properties.

These monomers quickly polymerize in the presence of water vapor, forming strong and durable bonds. Additionally, hydroquinone is often added as a stabilizer to prevent premature polymerization of the adhesive.

How It Bonds Materials?

When super glue comes into contact with a surface, it rapidly polymerizes upon exposure to moisture in the air.

This polymerization process creates a strong bond that adheres tightly to the materials being joined. The adhesive works best on non-porous surfaces where moisture is present to facilitate the bonding process.

Heat Resistance In Adhesives

When it comes to adhesives, heat resistance is a crucial factor to consider. Whether you’re working on a DIY project or an industrial application, understanding the heat resistance of adhesives, such as super glue, is essential for ensuring the longevity and reliability of the bond.

In this article, we’ll delve into the importance of heat resistance in adhesives and explore the factors that can affect it.

Importance Of Heat Resistance

Heat resistance in adhesives is vital for maintaining the integrity of bonded materials, especially in environments where temperature fluctuations occur.

High heat resistance ensures that the adhesive bond remains strong and durable, even when exposed to elevated temperatures. This is particularly important in applications such as automotive, aerospace, and electronic industries where components may experience thermal stress.

Factors Affecting Heat Resistance

Several factors can influence the heat resistance of adhesives, including the chemical composition of the adhesive, the type of substrates being bonded, and the application-specific temperature requirements.

Additionally, the curing process and bond line thickness can also impact the heat resistance of the adhesive bond. Understanding these factors is crucial for selecting the most suitable adhesive for a particular application.

Super Glue Under Heat

When it comes to the durability of super glue under heat, understanding its typical heat threshold and the effects of high temperature on adhesion is crucial.

Typical Heat Threshold

Super glue typically has a heat threshold ranging from 200 to 250 degrees Fahrenheit.

Effects Of High Temperature On Adhesion

- High temperatures can weaken the bond of super glue.

- Adhesion strength may decrease significantly under extreme heat.

- Exposure to heat can cause the glue to soften or become brittle.

- Heat exposure may lead to the glue losing its bonding properties.

Comparative Analysis

Super Glue’s heat resistance is a key factor in its comparative analysis. This adhesive is known for its ability to withstand high temperatures, making it a reliable choice for various applications. Whether it’s for industrial or everyday use, Super Glue’s heat resistance ensures a strong bond even in extreme conditions.

Super Glue Vs. Other Adhesives

When it comes to choosing the right adhesive for your project, a comparative analysis can help you make an informed decision. In this section, we will compare the performance of super glue with other adhesives in extreme conditions. Let’s dive in and see how super glue measures up against its counterparts.

Performance In Extreme Conditions

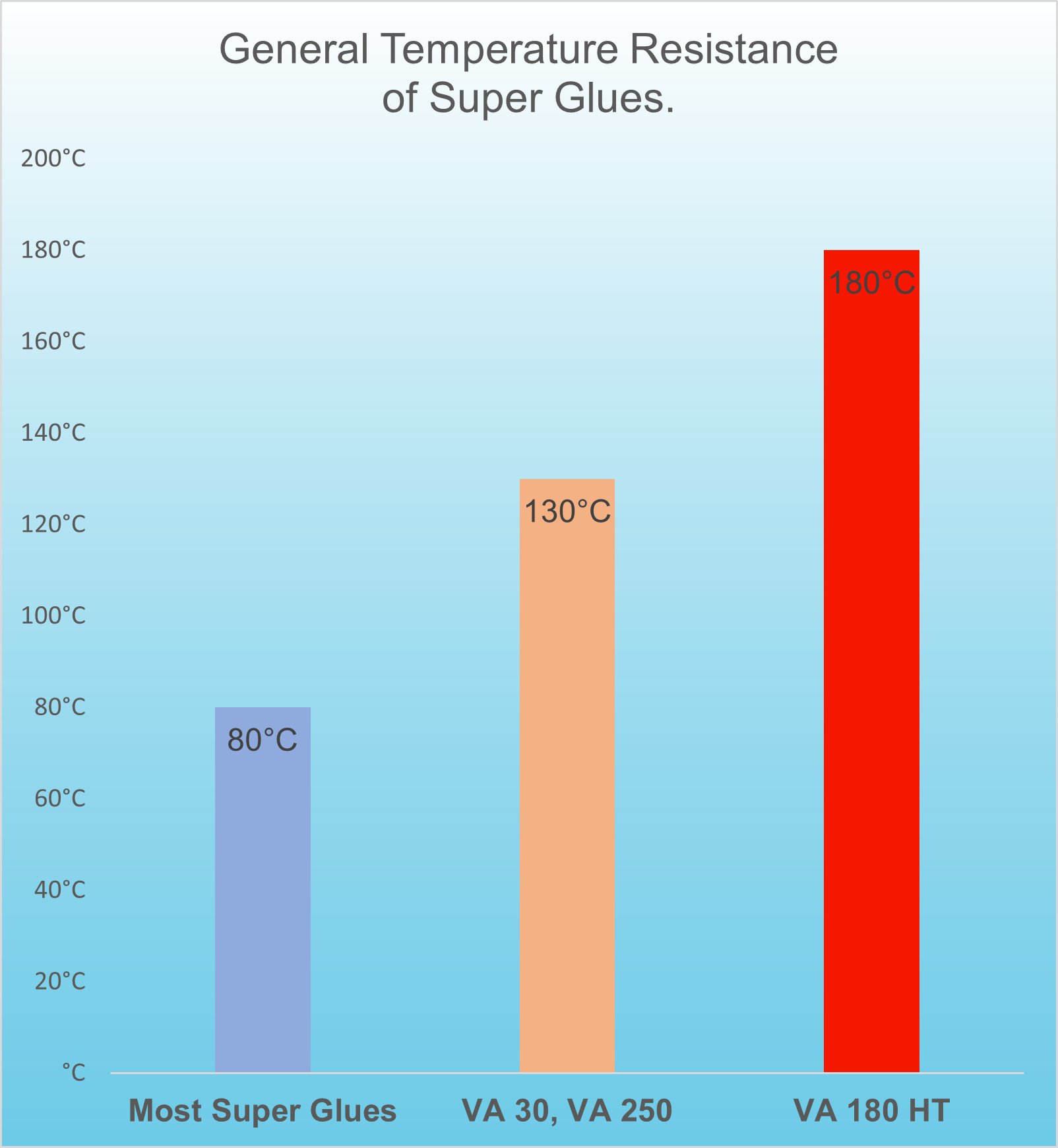

Super glue, also known as cyanoacrylate adhesive, is renowned for its quick-drying and strong bonding properties. But how does it perform in extreme conditions? Let’s take a closer look. In terms of heat resistance, super glue exhibits remarkable performance.

It can withstand temperatures ranging from -50°C to 120°C (-58°F to 248°F). This makes it suitable for a wide range of applications, including those that involve exposure to high temperatures.

Comparatively, other adhesives may have varying levels of heat resistance. Some adhesives, such as epoxy, offer excellent resistance to heat and can withstand even higher temperatures.

However, they may require longer curing times or additional steps for proper application. To give you a clearer picture, here’s a comparative analysis of super glue with other popular adhesives:

| Adhesive | Heat Resistance | Drying Time | Application Steps |

|---|---|---|---|

| Super Glue | Can withstand -50°C to 120°C (-58°F to 248°F) | Quick-drying | Simple application process |

| Epoxy | Can withstand higher temperatures | Longer curing time | Requires mixing of two components |

| Hot Glue | May soften or melt at high temperatures | Quick-drying | Requires a hot glue gun for application |

As you can see, super glue offers a good balance of heat resistance, quick drying, and ease of application. However, if your project requires adhesive with even higher heat resistance, epoxy might be a better choice, despite its longer curing time and more complex application process.

In conclusion, when it comes to heat resistance, super glue proves to be a reliable adhesive option for many applications. Its ability to withstand a wide range of temperatures makes it suitable for various projects.

However, for extreme heat conditions, it may be worth considering other adhesives like epoxy. Ultimately, the right choice depends on the specific requirements of your project.

Applications And Limitations

Super glue is generally not heat resistant and can weaken or melt under high temperatures. Its limitations include potential failure in heat-intensive applications, making it unsuitable for projects requiring heat resistance.

Suitable Environments For Use

Super glue, also known as cyanoacrylate adhesive, is a popular adhesive used for bonding materials together. It is a versatile adhesive that can be used in various environments, including:

- Household repairs – super glue can be used to fix broken items such as ceramic, glass, and plastic.

- Automotive repairs – super glue can be used to fix cracks in windshields, mirrors, and other plastic parts in the car.

- Electronic repairs – super glue can be used to repair electronic devices, including circuit boards and wires.

- Industrial use – super glue is commonly used in industrial settings to bond metals, plastics, and other materials together.

When To Avoid Using Super Glue?

While super glue is a popular adhesive, there are some limitations to its use. It is important to avoid using super glue in certain situations, including:

- High-temperature environments – super glue is not heat resistant and can break down when exposed to high temperatures. Therefore, it should not be used for applications that involve high temperatures, such as cooking appliances, engines, or other industrial equipment.

- Non-porous surfaces – super glue works best on porous surfaces that allow it to seep in and create a strong bond. It is not recommended for use on non-porous surfaces, such as metal or glass, as it may not bond properly.

- Items that will be subjected to heavy stress or pressure – while super glue is a strong adhesive, it may not be suitable for items that will be subjected to heavy stress or pressure. In these cases, it is recommended to use a more durable adhesive.

In conclusion, while super glue is a versatile adhesive with many applications, it is important to understand its limitations. It is not heat resistant and should not be used in high-temperature environments. Additionally, it may not be suitable for non-porous surfaces or items that will be subjected to heavy stress or pressure.

Enhancing Heat Resistance

Enhancing the heat resistance of super glue is crucial for various applications, whether in DIY projects or industrial settings. By understanding how to improve the heat resistance of super glue, you can ensure that your projects and applications remain strong and durable even in high-temperature environments.

Diy Tips

When using super glue for DIY projects that may be exposed to heat, consider the following tips to enhance its heat resistance:

- Choose a specialized heat-resistant super glue formula designed for high-temperature applications.

- Clean and prepare the bonding surfaces thoroughly to ensure maximum adhesion and heat resistance.

- Apply the super glue sparingly to avoid excess that could compromise its heat resistance.

- Consider using heat-resistant accelerators to improve the bonding strength in high-temperature conditions.

Industrial Solutions

In industrial settings, where heat resistance is paramount, super glue can be enhanced through various methods:

- Utilize heat-resistant adhesive formulations specifically engineered for industrial applications where high temperatures are a concern.

- Implement surface preparation techniques such as roughening or cleaning to optimize adhesion and heat resistance.

- Explore heat-curing processes to further enhance the super glue’s ability to withstand elevated temperatures.

- Consider using reinforcing materials in conjunction with the super glue to bolster heat resistance in industrial applications.

Safety Precautions

When using super glue, it’s essential to take proper safety precautions to avoid accidents and ensure a safe working environment. Here are some important safety measures to keep in mind when handling super glue:

Handling Super Glue

Proper handling of super glue is crucial to prevent accidents and ensure safety. Follow these guidelines:

- Avoid contact with skin and eyes as super glue can cause irritation.

- Work in a well-ventilated area to minimize inhalation of fumes.

- Keep the cap securely closed when not in use to prevent accidental spills.

- Store the super glue in a cool, dry place away from heat and direct sunlight.

Dealing With Accidents

In case of accidental exposure to super glue, follow these steps:

- Skin Contact: If super glue comes into contact with the skin, immediately wash the affected area with soap and water. Do not attempt to pull the skin apart as it can worsen the situation.

- Eye Contact: If super glue gets into the eyes, rinse with water for several minutes and seek medical attention immediately.

- Inhalation: If fumes are inhaled, move to a well-ventilated area and seek fresh air. If symptoms persist, seek medical help.

Future Of Adhesives

The future of adhesives is an exciting one, with advancements in technology leading to the development of stronger and more versatile options.

One question that often arises is whether super glue is heat resistant, making it a suitable choice for high-temperature applications. Let’s take a closer look.

Innovations In Heat Resistant Glues

Many adhesive manufacturers are constantly working to improve the heat resistance of their products, making them more reliable in extreme temperatures.

For example, some companies have developed high-temperature epoxy adhesives that can withstand temperatures up to 500°F.

Another option is silicone adhesives, which have excellent resistance to heat and can withstand temperatures up to 600°F. These innovations have expanded the range of applications for adhesives and offer greater reliability in high-temperature environments.

Predictions For Super Glue Evolution

While super glue is not typically known for its heat resistance, some manufacturers are working on improving this aspect of the product.

There are predictions that future advancements in super glue technology will result in heat-resistant options that can withstand temperatures up to 300°F or higher. This would make super glue a more versatile option for a wider range of applications, including those that involve exposure to heat.

As technology continues to advance, we can expect to see more innovations in adhesives, including improved heat resistance. Whether you’re working on a DIY project or an industrial application, it’s important to choose the right adhesive for the job to ensure a reliable and long-lasting bond.

Frequently Asked Questions

Can Superglue Withstand Heat?

Yes, superglue can withstand moderate heat but may degrade at extreme temperatures.

What Glue Is Resistant To Heat?

Choose heat-resistant adhesives like cyanoacrylate (super glue) or epoxy for applications requiring resistance to high temperatures.

Will Super Glue Come Undone With Heat?

Super glue does not come undone with heat. It is resistant to high temperatures and maintains its bond even when exposed to heat.

Is Gorilla Super Glue Heat Resistant?

Yes, Gorilla super glue is heat resistant, making it suitable for high-temperature applications.

Conclusion

Super glue can withstand moderate levels of heat, but it is not recommended for use in high-temperature applications. While it may hold up for a short period of time, prolonged exposure to heat can weaken the bond and cause it to break down.

It’s important to consider the specific needs of your project and choose the appropriate adhesive accordingly. Always read the manufacturer’s instructions and use caution when working with any type of glue.