Loctite 262 is a high-strength threadlocker, while Loctite 272 is a high-temperature and high-strength threadlocker. Both are designed for metal fasteners and provide secure, long-lasting bonds in demanding industrial applications.

Apart from their differences in temperature resistance and strength, both products are from the same reputable brand and are reliable choices for various fastening needs.

When selecting between Loctite 262 and 272, it is essential to consider the specific requirements of the application, including the level of heat exposure and the desired bond strength.

Understanding the unique features and benefits of each threadlocker can help in making an informed decision that meets the needs of the specific project or repair. Our in-depth comparison will help guide you in selecting the right product for your application.

Contents

Differences In Formulation

When it comes to choosing the right adhesive for a specific application, understanding the differences in formulation between products can make a significant impact on the success of a project.

Both Loctite 262 and Loctite 272 are high-performance threadlockers, each designed with unique chemical compositions optimized for different applications. Let’s explore the chemical composition of each to understand their individual characteristics and benefits.

Chemical Composition Of Loctite 262

Loctite 262 is a medium strength, oil tolerant threadlocker designed to secure and seal fasteners to prevent loosening caused by shock and vibration. Its chemical composition comprises dimethacrylate ester, polymerization inhibitor, and a stabilizer.

The dimethacrylate ester provides the adhesive properties, while the polymerization inhibitor extends the product’s shelf life. The stabilizer supports the overall stability and performance of the threadlocker.

Chemical Composition Of Loctite 272

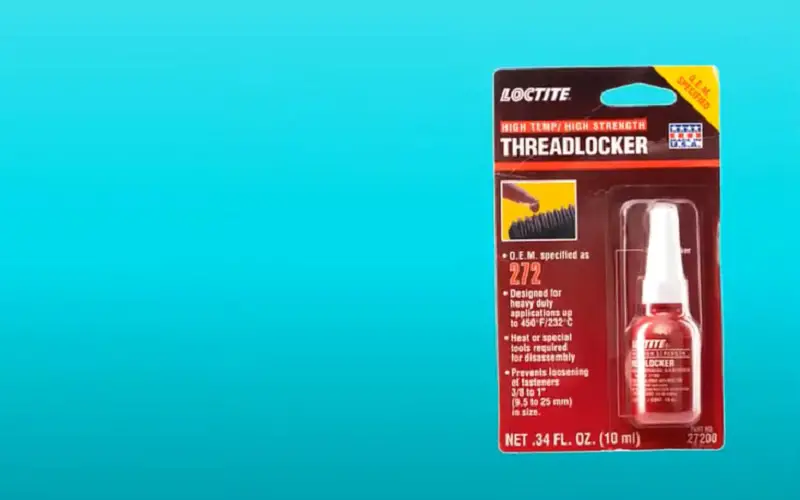

On the other hand, Loctite 272 is a high-strength, red-colored threadlocker that is specifically formulated for use with large or coarse threads up to M36.

Its chemical composition consists of dimethacrylate ester, polymerization inhibitor, and a higher concentration of adhesive fillers.

The increased amount of adhesive fillers provides additional bond strength, making it ideal for heavy-duty applications requiring maximum tensile and impact strength.

Application Areas

Loctite 262 and 272 are used in various application areas like automotive, industrial maintenance, and assembly. They both excel in high-strength metal bonding, but Loctite 272 offers increased temperature resistance compared to Loctite 262.

Choose the adhesive that fits your specific project requirements for optimal results. When it comes to choosing the right adhesive for your specific application, it’s essential to consider the suitability for different materials, as well as the recommended applications for Loctite 262 and 272.

Suitability For Different Materials

Using the right adhesive is crucial for ensuring a strong and durable bond. Loctite 262 is designed for applications where disassembly with hand tools is required.

It is ideal for locking and sealing threaded fasteners and is well-suited for use on all types of metals, including passive substrates such as stainless steel, aluminum, and plated surfaces.

On the other hand, Loctite 272 is formulated for applications that require very high-strength bonds on coarse or oily surfaces. It is especially suitable for fasteners that are unable to be removed with hand tools.

Recommended Applications For Loctite 262

Loctite 262 is commonly used in applications where vibration and shock resistance are required, such as securing nuts and bolts in automotive and mechanical assemblies.

It is also suitable for use in heavy-duty construction equipment, industrial machinery, and other high-stress environments where fasteners are subjected to extreme conditions.

This high-strength adhesive is also recommended for use on applications where disassembly with hand tools is necessary.

Recommended Applications For Loctite 272

When it comes to applications that demand extremely high-strength bonds, Loctite 272 shines. It is well-suited for heavy-duty applications in the automotive, aerospace, and industrial sectors, where a reliable and permanent locking and sealing solution is essential.

Additionally, Loctite 272 is suitable for use on surfaces that are coarse or oily, making it a go-to choice for challenging environments. In conclusion, both Loctite 262 and 272 offer exceptional performance in different application areas and provide reliable solutions for various industrial needs.

Whether you need to secure fasteners in high-stress environments or require a strong, permanent bond on coarse or oily surfaces, these adhesives are designed to meet your specific requirements.

Strength And Cure Time

Loctite 262 and 272 are two high-performance adhesives that offer excellent strength and cure time. Both options provide reliable bonding solutions for various applications. Choose the one that suits your specific needs for optimal results.

Loctite 262 and Loctite 272 are popular adhesives known for their strength and cure time differences. Let’s delve into the comparison of strength characteristics and cure time differences between these two products.

Comparison Of Strength Characteristics

Loctite 262 vs 272 in terms of strength shows Loctite 272 offer high strength on all metals & passive substrates. Loctite 262 is best for applications where parts must be disassembled. Loctite 272 is ideal for applications where high resistance is needed against heavy shock, vibration, or jarring.

Cure Time Differences Between Loctite 262 And 272

Loctite 262 enables a cure time of 2 hours vs. Loctite 272 with a faster cure time of 1 hour. Loctite 272 provides quicker fixturing for parts that need to be handled sooner.

When choosing between Loctite 262 and 272, consider the specific requirements of your application to determine which adhesive suits your needs best.

Temperature Resistance

When it comes to choosing the right adhesive for your high-temperature applications, Loctite offers a range of options.

In this article, we will compare two popular Loctite products, Loctite 262 and Loctite 272, and evaluate their temperature resistance capabilities.

Specifically, we will discuss their performance under high temperatures and the impact of temperature variation on bonding.

Performance Under High Temperatures

Loctite 262 and Loctite 272 are both well-known for their exceptional performance in high-temperature environments. These adhesives are specially formulated to withstand extreme heat, ensuring a strong and reliable bond even in challenging conditions.

Loctite 262 is a high-strength threadlocker designed for applications that require resistance to heat, chemicals, and vibrations. With a temperature resistance of up to 230°C (446°F), it can handle the demanding conditions of automotive, marine, and industrial applications.

On the other hand, Loctite 272 is a high-temperature threadlocker with an even higher temperature resistance. It can withstand temperatures up to 232°C (450°F), making it suitable for heavy-duty applications that involve exposure to extreme heat, such as aviation and oil and gas industries.

Impact Of Temperature Variation On Bonding

Temperature variations can have a significant impact on the bonding performance of adhesives. However, both Loctite 262 and Loctite 272 excel in maintaining their bond strength even in the face of temperature fluctuations.

Loctite 262 exhibits excellent thermal stability, allowing it to maintain its bond integrity under varying temperature conditions. Whether it’s exposed to heat or cold, this adhesive remains reliable, ensuring your bonded assemblies stay securely in place.

Similarly, Loctite 272 demonstrates outstanding temperature resistance, enabling it to withstand the rigors of thermal cycling without compromising its bonding performance. This makes it an ideal choice for applications that experience frequent temperature changes.

In conclusion, both Loctite 262 and Loctite 272 offer impressive temperature resistance capabilities. Whether you need a high-strength adhesive for industrial machinery or a reliable threadlocker for aerospace applications, these Loctite products have got you covered.

With their exceptional performance under high temperatures and ability to withstand temperature variations, they ensure your bonded assemblies stay secure and reliable.

Storage Requirements

Proper storage of Loctite adhesives is crucial for maintaining their effectiveness and extending their shelf life.

Loctite 262 and Loctite 272 are two popular threadlockers that require specific storage conditions to ensure their optimal performance.

Here is a breakdown of the proper storage requirements for each product:

Proper Storage Conditions For Loctite 262

Loctite 262 is a high-strength threadlocker designed for permanent assemblies. To keep it in the best possible condition, it is important to store it correctly by following these guidelines:

- Store Loctite 262 in a cool and dry place, ideally at a temperature between 8°C and 21°C (46°F and 70°F).

- Avoid exposing the adhesive to direct sunlight or extreme temperatures, as this can lead to degradation and reduce its effectiveness.

- Ensure the container is tightly sealed after each use to prevent air and moisture from entering, which can cause the adhesive to dry out.

- Keep Loctite 262 away from sources of ignition, as it is flammable.

By following these storage conditions, you can maximize the shelf life and maintain the quality of Loctite 262, ensuring it is ready for use whenever you need it.

Proper Storage Conditions For Loctite 272

Loctite 272 is a high-temperature threadlocker ideal for applications where disassembly may be necessary.

It has its own specific storage requirements to ensure its efficacy and longevity:

- Store Loctite 272 in a cool and dry environment, maintaining a temperature range between 8°C and 21°C (46°F and 70°F).

- Avoid exposing the adhesive to direct sunlight and extreme temperatures, which can degrade its performance.

- Close the container tightly to prevent air and moisture from entering, as prolonged exposure to these elements can cause the adhesive to harden or lose its effectiveness.

- Keep Loctite 272 away from sources of heat, sparks, and flames, as it is flammable.

By adhering to these proper storage conditions, you can ensure that Loctite 272 remains in optimal condition, ready for use whenever you require it.

Cost Analysis

Compare the cost analysis between Loctite 262 and 272 for better decision-making. Understand the difference in pricing and benefits to optimize your budget effectively.

Price Comparison Between Loctite 262 And 272

Loctite 262 costs slightly less than Loctite 272, making it a preferred choice for some budget-conscious customers.

Value For Money Assessment Based On Application Needs

User Preferences

When it comes to selecting the right threadlocker for a specific application, user preferences play a significant role.

Professionals and users often have their own insights and experiences when it comes to using Loctite 262 and 272, which ultimately influences their preferences.

Feedback From Professionals And Users

Professionals and users have varying feedback on the performance and suitability of Loctite 262 and 272 in different applications. Their experiences provide valuable insights into the effectiveness of each product.

Factors Influencing The Choice Between Loctite 262 And 272

Several factors influence the selection between Loctite 262 and 272, including:

- Environmental conditions

- Application type

- Required strength

- Curing time

- Serviceability

Frequently Asked Questions On Loctite 262 Vs 272

What Are The Uses For Loctite 262?

Loctite 262 is used for locking and sealing threaded fasteners to prevent loosening. It is suitable for heavy-duty applications in industries like automotive, construction, and manufacturing.

What Is Similar To Loctite 262?

Similar products to Loctite 262 include Permatex High-Temperature Threadlocker Red and 3M Scotch-Weld Threadlocker TL70.

What Is The Difference Between Loctite 277 And Loctite 272?

Loctite 277 is for high strength threadlocking, while Loctite 272 is for medium strength. Choose based on required bond strength.

Can Loctite 262 Be Removed?

Yes, Loctite 262 can be removed.

Conclusion

Both Loctite 262 and Loctite 272 are exceptional threadlockers offering reliable performance.

While 262 is ideal for applications requiring high strength and temperature resistance, 272 excels in retaining heavy-duty fasteners. Consider the specific needs of your project and make an informed choice accordingly.

By using the right Loctite product, you can ensure secure and long-lasting assemblies for your industrial applications. Choose wisely and enjoy the benefits of these top-notch threadlockers.