Loctite 242 and 243 are two types of adhesives used for different purposes. Loctite 242 is a medium strength threadlocker that is ideal for securing threaded fasteners, while Loctite 243 is a medium strength oil-tolerant threadlocker designed for use on fasteners that are exposed to oil or contaminants.

Both adhesives provide reliable and durable bonds and prevent loosening of fasteners due to vibration or shock.

Contents

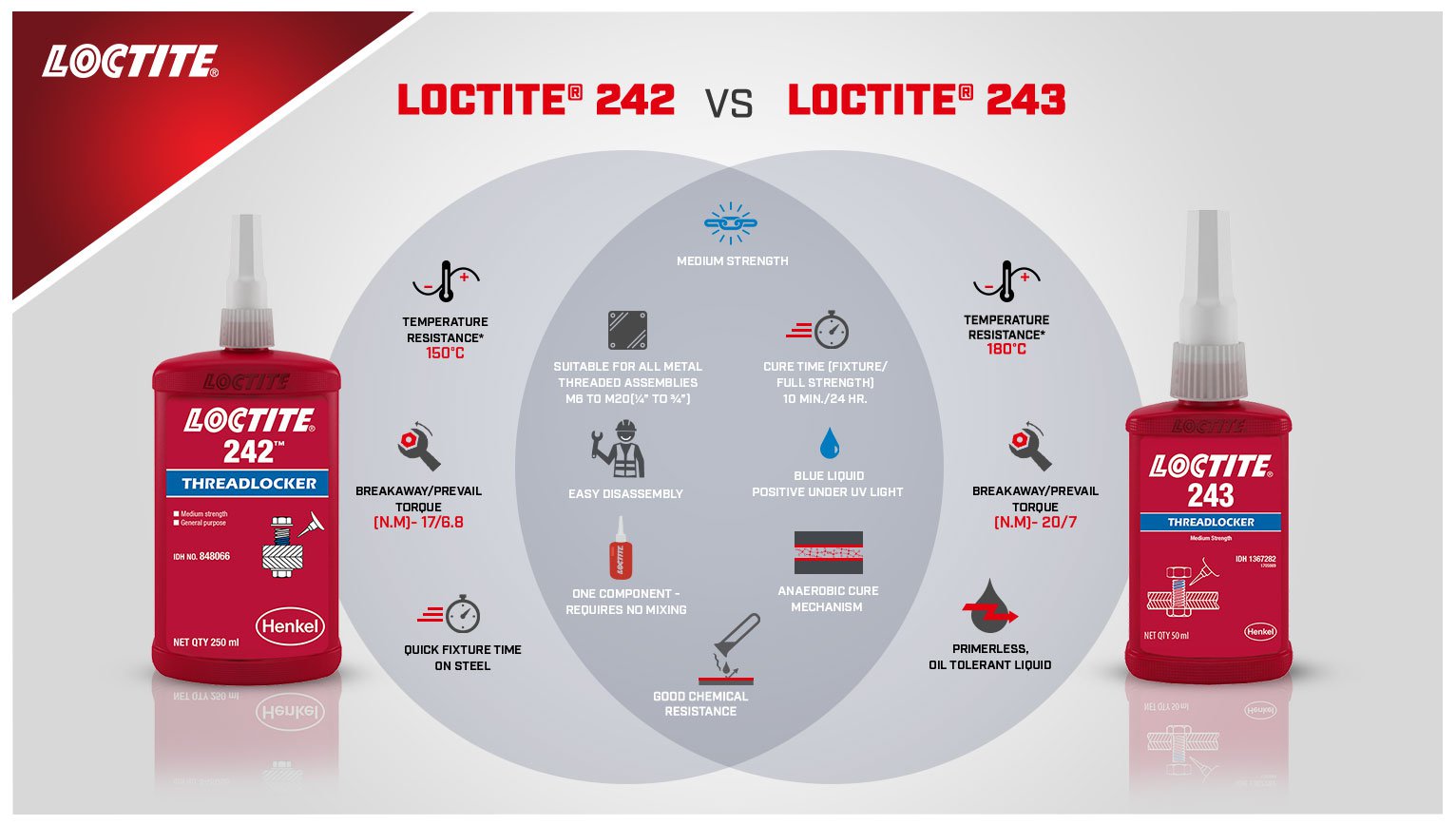

Loctite 242 Vs Loctite 243

Composition

When it comes to choosing the right adhesive for your specific application, understanding the composition of the adhesive is crucial.

Loctite 242 and 243 are both popular threadlocker adhesives with notable differences in their composition that make each suitable for different purposes.

Ingredients In Loctite 242

Loctite 242 is composed of several key ingredients that contribute to its effectiveness as a threadlocker adhesive. The main ingredients in Loctite 242 include:

- Dimethacrylate Ester

- Polysulfide oligomer

- Carbon Black

- Aliphatic Urethane Acrylate

Ingredients In Loctite 243

On the other hand, Loctite 243 contains a distinct set of ingredients compared to Loctite 242. The composition of Loctite 243 includes:

- Methacrylic Ester

- Aliphatic Urethane Acrylate

- Iron Oxide

- Polyalkyl Methacrylate

Curing Time

When comparing Loctite 242 and Loctite 243, the curing time is a crucial factor to consider. Both adhesives offer different curing times, which can impact the efficiency and productivity of your work.

Let’s delve into the curing times of Loctite 242 and Loctite 243 to understand their performance in various applications.

Curing Time Of Loctite 242

Loctite 242 is renowned for its quick curing time, which makes it an ideal choice for applications that require fast assembly or repositioning of components.

Upon application, Loctite 242 starts to cure within 20 minutes, providing a reliable and durable bond in a relatively short amount of time. This rapid curing time streamlines processes and reduces downtime, enhancing overall operational efficiency.

Curing Time Of Loctite 243

On the other hand, Loctite 243 offers a slightly longer curing time compared to Loctite 242.

Once applied, Loctite 243 typically cures within 24 hours, making it suitable for applications where extended curing time is acceptable, and long-term durability is paramount.

This extended curing time ensures that the adhesive thoroughly bonds the components, delivering robust and lasting connections.

Strength And Durability

When comparing Loctite 242 vs 243, the strength and durability of these two popular threadlockers play a crucial role in various applications.

Strength Comparison

The strength of a threadlocker refers to its ability to withstand external forces and prevent loosening of fasteners over time.

- Loctite 242 offers medium-strength bonding suitable for smaller-sized fasteners.

- Loctite 243 provides higher strength compared to 242, ideal for medium to larger-sized fasteners.

Durability Comparison

Durability is essential for ensuring the longevity of the bond and preventing corrosion or damage to the fasteners.

- Both Loctite 242 and 243 offer excellent resistance to vibration and shock, enhancing durability.

- Loctite 243 provides better resistance to oils and solvents, improving overall durability in challenging environments.

Applications

Loctite 242 and 243 are both thread lockers with high-strength formulas. Loctite 242 is designed for use on small fasteners up to 3/4″.

Loctite 243 is formulated for use on fasteners up to 1″. These products are commonly used in automotive and industrial applications for securing bolts, nuts, and screws.

Introduction: Applications

Loctite 242 and Loctite 243 are popular adhesive solutions that offer reliable and durable bonding for a variety of applications. These threadlockers are designed to prevent loosening and leakage of fasteners in mechanical assemblies.

While both products serve similar purposes, they have distinct characteristics and are better suited for specific applications. In this section, we will explore the common uses of Loctite 242 and Loctite 243, helping you understand which one is the right choice for your specific needs.

Common Uses Of Loctite 242

Loctite 242 is a medium-strength threadlocker with a wide range of applications. Here are some common uses where Loctite 242 can deliver exceptional performance:

- Securing nuts and bolts in machinery and equipment assemblies

- Locking screws in electrical connectors and control panels

- Preventing vibration-induced loosening of fasteners in motors and pumps

- Sealing threaded connections in hydraulic systems and plumbing fixtures

- Protecting fasteners from corrosion and rust in outdoor applications

Common Uses Of Loctite 243

Loctite 243, on the other hand, is a versatile threadlocker that offers medium strength with added oil tolerance. Its specific applications include:

- Securing fasteners in automotive assemblies, such as engines and transmissions

- Locking bolts and studs in heavy machinery, ensuring stability and reliability

- Preventing loosening of screws in appliances and electronic devices

- Sealing and securing pipe fittings in plumbing systems

- Providing resistance to vibration and shock in industrial equipment

Both Loctite 242 and Loctite 243 are ideal for preventing loosening and leakage in threaded connections. However, it’s essential to select the right product based on the specific requirements of your application.

Whether you need medium strength or oil tolerance, Loctite has a threadlocker that will meet your needs effectively. By choosing the appropriate adhesive, you can ensure your assemblies remain secure and reliable over time.

Storage And Shelf Life

Proper storage of adhesives is crucial for ensuring their effectiveness and longevity. Loctite 242 and Loctite 243 are two popular adhesives known for their exceptional performance and versatility.

Understanding the ideal storage conditions for these products is essential to maintain their quality and extend their shelf life. In this article, we will discuss the storage recommendations for Loctite 242 and Loctite 243.

Storage Recommendations For Loctite 242

When it comes to storing Loctite 242, there are a few key considerations to keep in mind:

- Store the adhesive in a cool, dry place with a temperature range between 8°C and 21°C (46°F to 70°F).

- Avoid exposure to direct sunlight or extreme temperatures as it can affect the adhesive’s performance and stability.

- Ensure that the container is tightly sealed after each use to prevent moisture from entering and compromising the adhesive’s quality.

- Organize the storage area to minimize the risk of accidental damage or mishandling.

Storage Recommendations For Loctite 243

When storing Loctite 243, follow these guidelines to maintain its effectiveness:

- Store the adhesive in a cool, dry location with a temperature range of 8°C to 21°C (46°F to 70°F).

- Avoid exposing the adhesive to direct sunlight or extreme temperatures as it may degrade the adhesive properties.

- Ensure the container is tightly sealed to prevent any moisture ingress which can damage the adhesive’s integrity.

- Keep the storage area clean and organized to reduce the risk of accidental spills or mishandling.

By following these storage recommendations for both Loctite 242 and Loctite 243, you can extend their shelf life and ensure optimal performance when you need it most.

Cost

When considering the difference between Loctite 242 and 243, cost is a critical factor to evaluate.

Price Difference Between Loctite 242 And 243

Loctite 242 and 243 products have slight cost variations due to their unique formulations and applications.

| Product | Price |

|---|---|

| Loctite 242 | $X |

| Loctite 243 | $Y |

Value For Money Comparison

- Loctite 242: Great for general purposes and offers cost-effective sealing.

- Loctite 243: Provides enhanced performance, ideal for critical applications, giving better value for its price.

Frequently Asked Questions For Loctite 242 Vs 243

Is Loctite 242 The Same As 243?

Yes, Loctite 242 and 243 are not the same. They have different specifications and applications.

What Is Loctite 242 Used For?

Loctite 242 is used for securing and sealing threaded fasteners to prevent loosening due to vibrations.

What Is Loctite 243 Good For?

Loctite 243 is good for locking and sealing nuts, bolts, and studs. It prevents loosening from vibration and protects against corrosion.

Is Loctite 242 Or 243 For Bike?

Loctite 242 and 243 are suitable for bike applications.

Conclusion

In the battle of Loctite 242 vs 243, both hold their ground for securing threaded assemblies. Depending on your specific needs, choose the right formula.

Remember, Loctite 242 offers medium strength, while Loctite 243 is oil-resistant. Make an informed choice for optimal results in your projects.