Views: 19

PVC glue typically takes around 24 hours to dry completely. Factors like temperature and humidity can affect drying time.

PVC glue is commonly used in plumbing projects to join PVC pipes and fittings securely. Understanding how long PVC glue takes to dry is crucial for ensuring the success of your project.

In this blog post, we will explore the drying process of PVC glue, factors that can impact drying time, and tips for achieving the best results when using PVC glue.

By the end of this article, you will have a clear understanding of how long you should wait before testing the strength of your PVC pipe joints. Let’s dive in and learn more about the drying time of PVC glue!

Contents

Introduction To PVC Glue

When it comes to working with PVC pipes, using the right adhesive is crucial for strong and durable connections. One of the most common adhesives used for PVC pipes is PVC glue.

What Is Pvc Glue?

PVC glue, also known as solvent cement, is a specially formulated adhesive designed to bond PVC pipes and fittings together permanently. It works by chemically softening the surfaces of the PVC material, allowing them to fuse together when the solvent evaporates.

Importance In Diy And Professional Projects

Whether you are working on a DIY plumbing project at home or a professional installation job, using PVC glue is essential for creating leak-proof connections that can withstand pressure and time.

Understanding Drying Vs. Curing

Understanding the difference between drying and curing is crucial when working with PVC glue. While drying can take as little as 15 minutes, curing requires at least 24 hours for a strong bond.

It’s important to follow the manufacturer’s instructions and allow sufficient time for the glue to cure before handling the PVC material.

Understanding Drying vs. Curing The Drying Process When PVC glue is applied, the drying process begins. Initially, the solvent in the glue evaporates, leaving behind a thin layer of adhesive on the surfaces being joined.

This initial drying phase typically takes around 15 to 30 minutes, depending on factors such as temperature and humidity. Once the solvent has evaporated, the glue is no longer in its liquid state and the joint can be handled, but it is not yet fully cured.

Curing: The Chemical Bond Curing is the process by which PVC glue forms a strong, permanent bond. During this phase, the adhesive undergoes a chemical reaction that creates cross-links between the molecules, resulting in a solid and durable bond.

While the initial drying process may only take a short time, complete curing can take up to 24 hours or longer, depending on the type of PVC glue and environmental conditions.

In summary, while the drying process allows the solvent to evaporate and the glue to set, curing is essential for the adhesive to develop its full strength and durability. Understanding the distinction between drying and curing is crucial for ensuring the success of PVC pipe bonding projects.

Factors Influencing Drying Time

Temperature And Humidity

High temperatures and low humidity accelerate drying process.

Type Of Pvc Glue

Fast-drying PVC glue sets quicker than regular formulas.

Thickness Of The Application

Thicker applications may require longer drying times.

Standard Drying Times

PVC glue typically takes around 24 hours to fully dry and cure. It is important to allow this standard drying time to ensure a strong and secure bond for your PVC projects.

Quick Set Glues

When it comes to quick set glues for PVC, you can expect a faster drying time compared to regular PVC glues. These adhesives are specifically designed for projects that require a quick bond and immediate use.

The drying time for quick set glues can vary depending on the brand and specific product, but on average, it typically takes around 10 to 15 minutes for the glue to set and approximately 2 hours for it to fully cure.

Regular Pvc Glues

Regular PVC glues, also known as solvent cements, are commonly used for joining PVC pipes and fittings. These glues require a slightly longer drying time compared to quick set glues.

The drying time for regular PVC glues can range anywhere from 30 minutes to several hours, depending on various factors such as temperature, humidity, and the type of PVC being bonded.

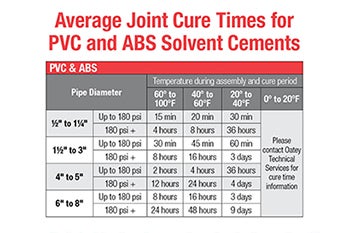

To give you a better idea of the standard drying times for regular PVC glues, here is a table summarizing the average drying times based on common brands:

| Brand | Average Drying Time |

|---|---|

| Brand A | 30 minutes |

| Brand B | 1 hour |

| Brand C | 2 hours |

| Brand D | 4 hours |

Please note that these drying times are approximate and can vary depending on factors such as temperature, humidity, and the specific conditions of your project.

It is always recommended to refer to the instructions provided by the manufacturer for the most accurate drying time information.

In conclusion, the drying time for PVC glues can vary depending on the type of glue used. Quick set glues typically dry within 10 to 15 minutes, while regular PVC glues can take anywhere from 30 minutes to several hours to fully dry.

It is important to allow sufficient drying time before handling or putting pressure on the bonded PVC joints to ensure a strong and secure connection.

Tips For Faster Drying

When it comes to working with PVC pipes, using PVC glue is an essential step in ensuring a secure and long-lasting joint. However, waiting for the glue to dry can be a time-consuming process. Fortunately, there are tips for faster drying that can help you speed up the process.

Proper Application Techniques

One of the most important factors in ensuring fast drying time is the proper application of the PVC glue. Here are some tips:

- Make sure that the surfaces to be glued are clean and free from debris.

- Apply the glue evenly, using a brush or applicator.

- Avoid applying too much glue, as this can slow down the drying process.

- Join the two surfaces immediately after applying the glue.

- Hold the joint firmly in place for at least 30 seconds to ensure a secure bond.

Optimizing Environmental Conditions

The environment in which you are working can also have an impact on the drying time of PVC glue. Here are some tips for optimizing environmental conditions:

| Condition | Optimal Range |

|---|---|

| Temperature | Between 40°F and 100°F |

| Humidity | Between 40% and 60% |

| Ventilation | A well-ventilated area |

By following these tips for faster drying, you can ensure that your PVC glue dries quickly and securely, allowing you to move on to the next step in your project with confidence.

Safety Precautions

When it comes to working with PVC glue, it’s important to prioritize safety. By following a few simple precautions, you can ensure a safe and successful project. Here are some key safety measures to keep in mind:

Ventilation Is Key

Proper ventilation is crucial when working with PVC glue. The fumes emitted during the drying process can be harmful if inhaled in large quantities.

To minimize the risk, make sure you are working in a well-ventilated area. Open windows and doors to allow fresh air to circulate, or use fans to increase air circulation. This will help to dissipate the fumes and reduce the risk of inhalation.

Personal Protective Equipment

Wearing the appropriate personal protective equipment (PPE) is essential when handling PVC glue. This includes safety goggles or glasses to protect your eyes from potential splashes or drips.

Additionally, wearing gloves will prevent direct contact with the glue, which can cause skin irritation. It is important to choose gloves that are resistant to the specific type of adhesive you are using. Always read the label and follow the manufacturer’s recommendations for PPE.

Furthermore, it’s important to note that PVC glue should be handled with care. Avoid contact with your skin or eyes, and if accidental contact occurs, immediately rinse the affected area with water and seek medical attention if necessary.

Testing For Dryness

When it comes to PVC glue, ensuring that it has fully dried is crucial for the success of your project. Testing for dryness is a vital step to guarantee the bond is strong and durable. In this section, we will explore the simple methods for testing the dryness of PVC glue and when to apply pressure.

Simple Methods

There are several straightforward ways to test if PVC glue has dried thoroughly. One of the simplest methods is to gently tap the glued components with a small tool or your finger.

If the surface feels firm and no longer tacky, the glue has likely dried. Additionally, inspecting the color change of the glue from its wet state to a dry, clear appearance can also indicate that it is ready for pressure.

When To Apply Pressure?

After confirming that the PVC glue has dried using the simple methods mentioned above, it is essential to know when to apply pressure. This typically involves waiting for the recommended drying time specified on the PVC glue product.

Additionally, if the glued components are load-bearing or will be subject to stress, allowing extra time beyond the specified drying period is advisable to ensure the bond is fully cured and strong.

Common Mistakes To Avoid

When using PVC glue, it’s essential to be aware of common mistakes that can impact the drying process. By avoiding these errors, you can ensure a successful bond and prevent potential issues down the line.

Overapplication

Applying too much PVC glue can lead to prolonged drying times and weaken the bond. Excessive glue can also result in messy, uneven joints, compromising the overall integrity of the connection. It’s crucial to apply a moderate and uniform amount of glue to achieve optimal results.

Ignoring Temperature And Humidity

The temperature and humidity of the environment play a significant role in the drying process of PVC glue. Ignoring these factors can lead to inadequate adhesion and weak joints. Be mindful of the recommended temperature and humidity range specified by the manufacturer for the best outcomes.

Advanced Quick Set Secrets

When it comes to working with PVC pipes, time is of the essence. Waiting for the glue to dry can be a frustrating process, especially if you’re on a tight schedule. Luckily, there are some advanced quick set secrets that can help you speed up the drying time of PVC glue.

Using Accelerators

If you’re looking to cut down on the drying time of PVC glue, using accelerators is a game-changer. These special additives are designed to speed up the chemical reaction between the glue and the PVC pipe, resulting in a faster drying time.

By applying an accelerator before using the glue, you can significantly reduce the waiting time and get your project done in no time.

Choosing The Right Product For The Job

Not all PVC glues are created equal. Some products are specifically formulated for quick drying, making them perfect for time-sensitive projects. When choosing the right product for the job, look for those that are labeled as “fast-setting” or “quick-drying.”

These glues typically have a shorter drying time compared to regular PVC glues, allowing you to complete your project in a fraction of the time. Moreover, it’s important to consider the temperature and humidity conditions in your work area.

High temperatures and low humidity can accelerate the drying process, while low temperatures and high humidity can slow it down. By choosing a PVC glue that is optimized for the conditions you are working in, you can ensure a faster and more efficient drying time.

In addition to using accelerators and choosing the right product, there are a few additional tips to keep in mind when working with PVC glue.

Make sure to clean and dry the surfaces that will be glued together before applying the adhesive. This helps to create a strong bond and promotes faster drying. Additionally, applying a thin and even layer of glue will also aid in reducing the drying time.

So, the next time you’re working on a project that involves PVC pipes, remember these advanced quick set secrets. By using accelerators, choosing the right product, and following proper application techniques, you can minimize the waiting time and achieve fast and reliable results.

Frequently Asked Questions

How Long Should Pvc Glue Dry Before Turning On Water?

Allow PVC glue to dry for 24 hours before turning on water to ensure a secure seal.

How Long After Gluing Pvc Can You Test?

You can test PVC after gluing it within 24 hours. Allow adequate time for the glue to set before testing.

What Is The Fastest Cure Time For Pvc Glue?

The fastest cure time for PVC glue is typically around 15 minutes, depending on the specific brand and conditions.

How Long To Wait For Cpvc Glue To Dry Before Turning On Water?

Wait for at least 30 minutes for CPVC glue to dry before turning on the water. This will ensure that the glue has completely bonded and set, preventing any leaks or damage to the piping system.

Conclusion

The drying time of PVC glue varies based on factors like temperature and humidity. Understanding these variables can help ensure a successful bonding process.

By following manufacturer recommendations and allowing sufficient drying time, you can achieve strong and durable PVC joints for your projects.