Flex Seal and epoxy are two popular options used for sealing and repair projects.

When it comes to sealing and repairing projects, Flex Seal and Epoxy are two widely recognized products. While both serve the purpose of versatile adhesives, they possess different characteristics, which makes them suitable for specific applications.

In this article, we’ll delve into an in-depth comparison to help you make an informed decision on which product best suits your needs.

Contents

Flex Seal Vs Epoxy

Flex Seal Overview

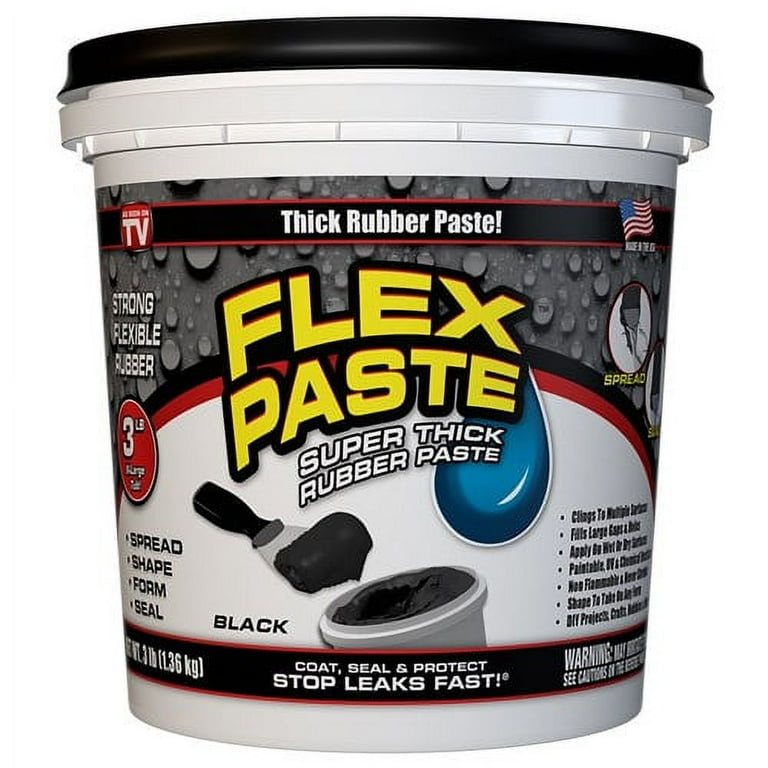

Flex Seal is a liquid rubber sealant that forms a waterproof coating when applied to surfaces. It comes in various forms, including liquid spray, aerosol spray, and sealant tape, making it suitable for different types of repairs and sealing projects.

This versatile product offers a quick and easy solution for a wide range of applications, from fixing leaks to creating a protective barrier against moisture and corrosion.

Epoxy Overview

Epoxy, on the other hand, is a strong adhesive and coating material that consists of a resin and a hardener.

When these two components are mixed together, they form a durable and long-lasting bond, ideal for repairing and bonding various materials such as metal, wood, glass, and concrete.

Epoxy is known for its high strength, chemical resistance, and ability to fill gaps and uneven surfaces, making it a popular choice in construction, automotive, and DIY projects.

Application Differences

When considering the differences between Flex Seal and Epoxy, the applications of each product play a crucial role in determining their usability for specific projects.

Understanding the unique application differences between Flex Seal and Epoxy is essential to make an informed decision about which product is best suited for your needs.

Flex Seal Applications

Flex Seal, known for its versatility, is primarily used for sealing and protecting surfaces. It is commonly applied to repair leaks in gutters, roofs, and plumbing, as well as for coating and protecting various surfaces such as concrete, wood, and metal.

Its flexible nature enables it to be used on a wide range of materials, making it a popular choice for quick and effective fixes.

Epoxy Applications

Epoxy, on the other hand, is widely utilized for bonding and repairing surfaces. Its strong adhesive properties make it ideal for tasks such as joining materials together and patching up cracks.

Epoxy is commonly used in applications that require high strength and durability, such as in construction and automotive repairs.

Durability And Longevity

When comparing Flex Seal vs. Epoxy, it’s essential to consider their durability and longevity. Both products claim to provide long-lasting results, but how do they stack up against each other in terms of durability?

Flex Seal Durability

Flex Seal offers a flexible rubber coating that claims to provide a protective barrier against water, leaks, and corrosion. It is known for its ability to seal cracks and leaks effectively.

- Resistant to water and weather damage.

- Provides a quick and easy solution for various repairs.

- Can be applied to a wide range of surfaces.

Epoxy Durability

Epoxy, on the other hand, is a strong adhesive and sealant that forms a tough, durable bond when cured. It is commonly used for heavy-duty repairs and projects that require a high level of strength.

- Offers superior resistance to chemicals and heat.

- Creates a hard, protective coating over surfaces.

- Known for its long-lasting durability and strength.

When it comes to durability and longevity, both Flex Seal and Epoxy have their strengths and applications.

Flex Seal excels in providing a quick fix for minor repairs and sealing while Epoxy is preferred for projects requiring a strong, lasting bond.

Ease Of Use And Application

When it comes to choosing the right product for your DIY projects, ease of use and application are crucial factors to consider.

The application process can often determine how quickly and efficiently you can complete your project. Let’s take a closer look at the application processes of Flex Seal and Epoxy.

Flex Seal Application Process

Flex Seal is known for its user-friendly application process, making it an ideal choice for beginners as well as experienced DIY enthusiasts.

The application process involves just a few simple steps:

- Prepare the surface by cleaning it thoroughly and ensuring it is dry.

- Shake the can of Flex Seal well to activate the formula.

- Hold the can approximately 8 to 12 inches away from the surface and spray the desired area.

- Apply multiple coats if necessary, allowing each coat to dry for 24 hours before applying the next layer.

- Repeat the process until you achieve the desired level of sealing or coating.

In just a few easy steps, Flex Seal allows you to quickly seal leaks, repair cracks, and protect surfaces. Its spray-on application ensures even coverage and a smooth finish without the need for additional equipment or specialized skills.

Epoxy Application Process

The application process for epoxy requires a little more precision and attention to detail. Here are the steps involved:

- Prepare the surface by cleaning it thoroughly and ensuring it is dry.

- Mix the epoxy resin and hardener together according to the manufacturer’s instructions.

- Apply the mixed epoxy to the surface using a brush or roller, ensuring even coverage.

- Allow the epoxy to cure for the recommended time indicated on the packaging.

- Sand and smooth the surface if necessary before applying additional coats.

- Repeat the process for multiple coats as required.

Epoxy provides a strong and durable finish, but its application requires more precision and careful mixing. It is important to follow the instructions provided by the manufacturer to ensure proper curing and optimal results.

| Flex Seal | Epoxy |

|---|---|

| Easy spray-on application | Requires mixing and precise application |

| No specialized skills or equipment needed | Requires careful preparation and attention to detail |

| Quick drying time | Requires curing time for optimal results |

Both Flex Seal and Epoxy have their advantages and can be used for various applications. Flex Seal offers a convenient and hassle-free application process, making it ideal for quick fixes and smaller projects.

Epoxy, on the other hand, provides a strong and durable finish but requires more careful preparation and application. Consider your project needs and the level of ease you desire when choosing between the two.

Waterproofing Capabilities

When it comes to waterproofing, both Flex Seal and Epoxy offer impressive capabilities. Whether you need to fix a leak or protect a surface from water damage, these products provide effective solutions.

In this section, we’ll explore the waterproofing features of Flex Seal and Epoxy and help you decide which one is the better choice for your specific needs.

Flex Seal Waterproofing

Flex Seal is renowned for its exceptional waterproofing abilities. Designed to create a sturdy, watertight barrier, Flex Seal forms a flexible rubberized coating that prevents water penetration.

It works wonders on various surfaces, including metal, wood, plastic, and more. With its excellent adhesion properties, Flex Seal seals leaks effectively, whether it be on roofs, pipes, gutters, or even pool cracks.

- Boldly fills cracks, gaps, and holes to create a waterproof seal

- Protects surfaces against water damage and corrosion

- Works on a wide range of materials, including metal, wood, plastic, and more

- Simple application process for quick and efficient results

Epoxy Waterproofing

Epoxy is another popular choice for waterproofing various surfaces. This versatile adhesive provides exceptional bonding and sealing capabilities, making it a valuable tool for waterproofing projects.

Epoxy bonds strongly to a variety of materials and forms a durable, waterproof layer that effectively shields surfaces from moisture. Whether you need to seal a concrete floor or repair leaking pipes, epoxy provides a reliable and long-lasting solution.

- Creates a strong and waterproof seal to prevent leaks

- Provides excellent adhesion to various materials

- Ideal for sealing concrete, repairing pipes, and other waterproofing tasks

- Durable and long-lasting solution for protection against water damage

Cost Comparison

When comparing Flex Seal and Epoxy, understanding the cost aspect is crucial. Let’s delve into the cost breakdown of these two popular sealing solutions.

Flex Seal Cost

Flex Seal is known for its affordability, typically ranging from $12 to $30 per can, depending on quantity and type.

Epoxy Cost

Epoxy, on the other hand, tends to be more expensive, with prices averaging $20 to $50 per kit for small projects.

Cost Comparison Table

| Product | Average Cost |

|---|---|

| Flex Seal | $12 – $30 per can |

| Epoxy | $20 – $50 per kit |

Key point: Flex Seal is generally more budget-friendly compared to Epoxy.

Environmental Impact

When considering products like Flex Seal and epoxy, it’s essential to evaluate their environmental impact.

Understanding the ecological consequences of these products can help consumers make informed choices about their usage.

Let’s delve into the environmental impact of Flex Seal and epoxy to shed light on their sustainability.

Flex Seal Environmental Impact

Flex Seal, a popular rubberized sealant, has gained traction for its versatile application in sealing leaks and cracks. However, its environmental impact is a point of concern

The aerosol form of Flex Seal contains volatile organic compounds (VOCs) that contribute to air pollution and can harm the ozone layer.

Additionally, the disposal of empty Flex Seal aerosol cans can lead to environmental contamination if not managed properly.

- The production and transportation of Flex Seal contribute to carbon emissions.

- The non-biodegradable nature of Flex Seal raises concerns about its long-term impact on landfills.

Epoxy Environmental Impact

Epoxy, a resin adhesive known for its strong bonding properties, also has environmental implications. The manufacturing process of epoxy involves the use of chemicals that can pose risks to both human health and the environment.

Epoxy resins may contain harmful substances, such as bisphenol A (BPA), which can leach into the environment and impact aquatic ecosystems.

- The disposal of unused epoxy can lead to soil and water pollution.

- Some epoxy formulations require the use of solvents, contributing to air pollution.

Frequently Asked Questions For Flex Seal Vs Epoxy

Does Flex Seal Really Stop Leaks?

Yes, Flex Seal effectively stops leaks. It forms a flexible, watertight seal in a variety of materials. The product is ideal for repairing leaks in pipes, roofs, gutters, and more. It’s a convenient and reliable solution for stopping leaks.

What Will Flex Seal Not Stick To?

Flex Seal will not stick to surfaces that are oily, greasy, dirty, or wet. Additionally, it may not adhere well to certain plastics or silicone materials.

Will Flex Seal Stick To Epoxy?

Yes, Flex Seal can stick to epoxy surfaces. It forms a strong bond and provides a secure hold.

How Permanent Is Flex Seal?

Flex Seal provides a permanent solution for many types of repairs. Its strong adhesive creates a watertight seal that can withstand extreme conditions, making it a reliable choice for various applications. Whether you need to fix a leak or seal a crack, Flex Seal offers long-lasting results.

Conclusion

Both Flex Seal and Epoxy have their strengths and weaknesses. Flex Seal is great for quick fixes, while Epoxy offers durability and strength.

Consider your specific needs before choosing the right solution for your project. Experiment and find the best option for your project’s needs.