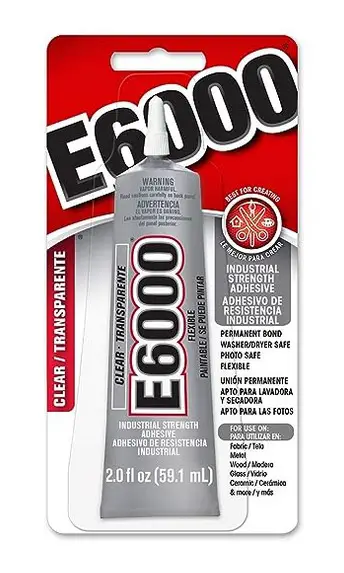

If you want to choosing between E6000 and E8000 glue, it’s important to consider their specific uses and properties. E6000 is a versatile adhesive that works well on a variety of materials, including metal, wood, glass, and fabric.

It provides a strong bond and remains flexible once cured. On the other hand, E8000 is often preferred for its superior durability and resistance to both water and extreme temperatures.

It can also bond to more challenging surfaces like plastics and rubber. Ultimately, the choice depends on the specific requirements of your project and the materials you’re working with.

Contents

E6000 Glue Vs E8000 Glue

Composition

E6000 and E8000 are popular adhesives known for their strong bonding capabilities. Understanding the composition of these glues is essential in determining their suitability for various projects.

Chemical Makeup Of E6000

E6000 is a versatile adhesive composed of polymer resin, toluene, and acetone. This combination results in a durable and flexible glue ideal for applications requiring a strong, long-lasting bond.

Chemical Makeup Of E8000

E8000 glue consists of ethylene-vinyl acetate copolymer and organic solvent. This formulation provides excellent adhesion to various materials and offers a waterproof seal, making it suitable for outdoor projects.

Strength And Durability

When it comes to choosing the right glue for your projects, strength and durability are key factors to consider. The last thing you want is for your hard work to fall apart or break due to weak bonding.

In this section, we will compare the bonding strength and durability of E6000 and E8000 glues under various conditions to help you make an informed decision.

Comparison Of Bonding Strength

When it comes to bonding strength, both E6000 and E8000 glues are known for their exceptional performance. However, there are some differences to be aware of.

- E6000 offers a strong bond with a tensile strength of up to 3,500 PSI (pounds per square inch). This makes it suitable for a wide range of materials, including metals, plastics, and more.

- On the other hand, E8000 takes bonding strength to the next level with a tensile strength of up to 5,000 PSI. This makes it ideal for heavy-duty applications that require an extra-strong bond.

Both glues provide excellent adhesion and can withstand heavy loads and stress. However, if you’re working on a project that requires an extremely strong bond, E8000 might be the better choice.

Comparison Of Durability Under Various Conditions

When it comes to durability, E6000 and E8000 glues are designed to hold up well under different conditions.

| Conditions | E6000 | E8000 |

|---|---|---|

| Temperature extremes | Can withstand temperatures ranging from -40°C to 82°C (-40°F to 180°F). | Can endure temperatures ranging from -50°C to 120°C (-58°F to 248°F). |

| Water resistance | Provides excellent water resistance once fully cured, making it suitable for outdoor applications. | Offers enhanced water resistance, making it a great choice for projects exposed to moisture and water. |

| Chemical resistance | Resistant to a wide range of chemicals, including gasoline, oil, and some solvents. | Offers superior resistance to various chemicals, making it ideal for applications where exposure to chemicals is expected. |

Both glues have impressive durability and can withstand challenging conditions.

However, if your project involves extreme temperature fluctuations, frequent exposure to water, or contact with chemicals, the additional durability offered by E8000 might be advantageous.

Overall, both E6000 and E8000 glues possess remarkable bonding strength and excellent durability. Your choice will ultimately depend on the specific requirements of your project and the conditions it will be exposed to.

Consider the strengths and differences outlined here to determine which glue will best suit your needs.

Application

Looking for the perfect glue? When comparing E6000 to E8000, consider the specific needs of your application. The right glue will ensure a strong and durable bond for your project.

When it comes to choosing the right adhesive for your projects, it’s essential to consider the specific application. Both E6000 and E8000 glues offer excellent bonding strength and versatility, but they do have some differences in terms of suitable uses.

Suitable Uses For E6000

E6000 glue is a popular and versatile adhesive that can be used for various applications.

Some of the suitable uses for E6000 include:

Bonding different materials: E6000 is ideal for bonding materials such as wood, glass, fabric, leather, metal, ceramics, and more. It provides a strong and durable bond that can withstand different environments.

Jewelry making: E6000 is widely used for jewelry making due to its excellent bond and flexibility. It is perfect for attaching beads, gems, and other embellishments to different jewelry components.

Craft projects: Whether you’re working on a DIY project or doing crafts with your kids, E6000 is a reliable choice. It can be used for bonding different materials together, such as paper, fabric, wood, and plastic, making it versatile for various craft projects.

Home repairs: With its strong bonding properties, E6000 is suitable for various home repairs. It can be used to fix loose tiles, repair broken household items, or even reinforce weak joints.

Suitable Uses For E8000

E8000 glue, on the other hand, is known for its exceptional adhesive strength and ability to bond different materials.

Here are some suitable uses for E8000:

Electronics repair: E8000 is commonly used in the electronics industry for repairing devices such as smartphones, tablets, and laptops. Its high elasticity and strong bond make it ideal for securing delicate components.

Industrial applications: E8000 is often used in manufacturing and industrial settings due to its excellent bonding strength. It can be used for bonding materials like rubber, plastic, metal, and more.

Outdoor projects: If you need an adhesive for outdoor projects, E8000 is a reliable choice. It is resistant to water, heat, and weather conditions, making it suitable for outdoor applications like sealing gaps, repairing outdoor gear, or even attaching decorations to outdoor surfaces.

Automotive repairs: E8000 is commonly used for automotive repairs, thanks to its resistance to gasoline, oil, and other automotive fluids. It can be used to bond various automotive components, such as plastic trim, rubber seals, and glass.

Both E6000 and E8000 glues have their applications, and understanding their suitable uses can help you choose the right adhesive for your specific project.

Whether you’re working on crafts, home repairs, electronics, or automotive projects, selecting the appropriate adhesive is crucial for a successful outcome.

Safety And Handling

When it comes to choosing between E6000 and E8000 glue, understanding the safety and handling aspects is crucial for a successful application.

Both adhesives are commonly used for crafting, repairs, and DIY projects, but they have differences that impact how they should be handled.

Considerations When Using E6000

- Store E6000 in a cool, dry place away from direct sunlight.

- Use E6000 in a well-ventilated area to avoid inhaling fumes.

- Wear protective gloves when handling E6000 to prevent skin irritation.

- Avoid contact with eyes and wash hands thoroughly after use.

Considerations When Using E8000

- Keep E8000 away from open flames or sources of ignition due to its flammable nature.

- Use E8000 in a well-ventilated area to prevent inhaling harmful vapors.

- Avoid skin contact with E8000 as it can cause irritation or allergic reactions.

- Store E8000 in a cool, dark place to maintain its effectiveness.

Drying Time And Curing

E6000 and E8000 are two popular adhesive glues that are widely used in various crafting, DIY, and repair projects. When it comes to choosing the right glue for your project, it’s important to consider factors such as drying time and curing.

These factors can significantly impact the overall success and durability of your project. In this section, we’ll compare the drying time and curing process of E6000 and E8000 glues to help you make an informed decision.

Comparison Of Drying Time

E6000: The drying time for E6000 glue can vary depending on the thickness of the application and environmental conditions. However, on average, it takes about 24 to 72 hours for E6000 to fully cure and set.

E8000: On the other hand, E8000 glue has a slightly faster drying time compared to E6000. It typically takes around 10 to 20 minutes for E8000 to become tacky, and the full curing process usually takes 24 to 48 hours.

Curing Process For Each Glue

E6000: The curing process for E6000 involves allowing the glue to air dry, forming a durable and flexible bond. Once the glue has dried, it reaches its maximum strength and can withstand various environmental conditions.

E8000: Similar to E6000, the curing process for E8000 involves air drying. However, E8000 is known for its quick-curing formulation, making it a great choice for projects that require a faster turnaround time.

Price And Availability

When it comes to choosing the right adhesive, understanding the price and availability is crucial. Let’s take a closer look at how E6000 and E8000 stack up against each other.

Cost Comparison

- Reasonably priced

- Offers good value for its cost

- Slightly higher in price compared to E6000

- Generally costlier due to its enhanced performance

Availability In The Market

Both E6000 and E8000 are widely available in the market, with E6000 being more commonly found due to its popularity. They can be purchased from various online retailers as well as hardware and craft stores, ensuring convenient accessibility for consumers.

Frequently Asked Questions Of E6000 Vs E8000 Glue

What Is The Difference Between B7000 And E6000?

B7000 is a multipurpose adhesive, suitable for various materials. E6000 is ideal for bonding jewelry and fabrics.

How Long Does It Take For E8000 Glue To Dry?

E8000 glue takes approximately 24 to 72 hours to fully dry. The drying duration may vary based on factors such as temperature and humidity. It’s important to allow sufficient time for the glue to set and bond effectively.

What Is The Difference Between B7000 And T8000 Glue?

B7000 and T8000 glues differ in their adhesive strength and flexibility. B7000 is more flexible, suitable for delicate items, while T8000 offers stronger adhesion for heavier objects. Both are versatile and widely used for different crafting and DIY projects.

What Is The Difference Between E6000 And F6000 Glue?

E6000 glue is a multi-purpose adhesive suitable for various materials. F6000 glue is a specific formula used for jewelry making.

Conclusion

After comparing E6000 and E8000 glue, the choice depends on the bonding requirement. E6000 has versatility, while E8000 offers faster drying.

Assess your project needs for a successful outcome. Experiment with both to find the best fit for your DIY endeavors.