Contact cement and rubber cement are two adhesive types. Contact cement creates a strong, permanent bond between two surfaces, while rubber cement provides a temporary, repositionable bond.

Both types are widely used in crafting and repairs due to their unique bonding qualities. Contact cement, commonly used for construction materials, requires both surfaces to be coated with adhesive and then pressed together, creating an immediate and durable bond.

On the other hand, rubber cement, often favored for temporary or artistic projects, allows for repositioning of the bonded items until the solvent evaporates, leaving a secure but removable bond. Understanding the differences between these two adhesives helps in choosing the right one for various applications.

Contents

Contact Cement Vs Rubber Cement

Composition

When it comes to choosing the right adhesive for your projects, it’s essential to understand the composition of contact cement and rubber cement. Knowing the ingredients of these adhesives can help you make an informed decision about which one is best suited for your specific applications.

Ingredients Of Contact Cement

Contact cement, commonly used for bonding laminate, wood, and other materials, is typically composed of:

- Neoprene

- Polychloroprene

- Resin

- Hexane

- Toluene

Ingredients Of Rubber Cement

Rubber cement, known for its ability to create temporary bonds and its widespread use in arts and crafts, typically contains:

- Heptane

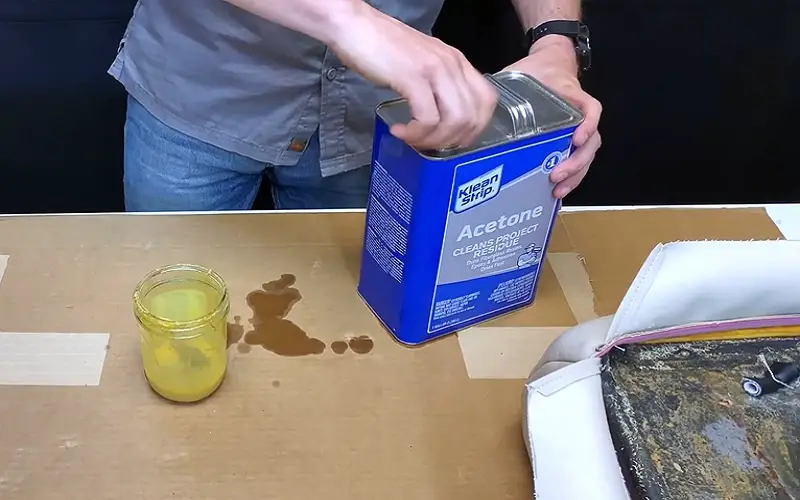

- Acetone

- Resin

- Ethyl acetate

- Hydrocarbon solvents

Application

When it comes to adhesives, it’s crucial to understand the right methods for applying contact cement and rubber cement. Proper application ensures a strong bond and effective results for your projects. Let’s delve into the specific techniques for each type of cement.

How To Apply Contact Cement

Applying contact cement requires precision and attention to detail. Here’s a step-by-step guide to ensure successful application:

- Clean the surfaces thoroughly, ensuring they are free from any dust or debris.

- Using a brush or roller, apply a thin, uniform coat of contact cement to both surfaces that need to be bonded.

- Allow the cement to dry for the specified time as per the product instructions.

- Once the cement is tacky to the touch, carefully align and press the surfaces together firmly.

- Apply pressure evenly across the bonded area to ensure a secure and durable connection.

How To Apply Rubber Cement

Application of rubber cement is a straightforward process. Follow these steps to achieve optimal results:

- Clean the surfaces to be bonded, ensuring they are free from any dirt or grease.

- Using a brush or applicator, apply a thin, even layer of rubber cement to both surfaces.

- Allow the cement to dry for a few minutes until it becomes tacky to the touch.

- Once the cement is tacky, carefully align the surfaces and press them together firmly.

- Apply even pressure to ensure a strong bond and allow the cement to set completely.

Bonding Strength

Bonding strength is a critical factor to consider when comparing contact cement and rubber cement.

Strength Of Bond In Contact Cement

Contact cement features a strong bond that is durable and long-lasting.

- Forms an instant bond upon contact

- Capable of holding heavy materials together

- Effective for permanent bonding applications

Strength Of Bond In Rubber Cement

Rubber cement provides a flexible bond suitable for various projects.

- Offers a versatile bonding solution

- Allows for repositioning of materials before setting

- Ideal for lightweight materials and temporary bonds

Drying Time

When comparing contact cement vs rubber cement, drying time plays a crucial role.

Contact cement generally dries faster, allowing for quicker bonding, while rubber cement requires more time to set properly. Consider the project timeline and specific needs before selecting the appropriate cement for optimal results.

Drying Time Of Contact Cement

Contact cement is known for its quick drying time, making it a popular choice for projects that require immediate bonding. The drying time of contact cement typically ranges from 15 to 30 minutes.

However, this can vary depending on several factors:

1. Temperature: Higher temperatures can speed up the drying time of contact cement, allowing you to move forward with your project more quickly.

2. Humidity: High humidity levels can prolong the drying time of contact cement. It is recommended to work in a well-ventilated area with low humidity for faster results.

3. Application method: The thickness and evenness of the contact cement layer can affect drying time. Thicker layers may take longer to dry, whereas thin and even application can expedite the process.

Drying Time Of Rubber Cement

Unlike contact cement, rubber cement has a slower drying time. This makes it ideal for projects that require repositioning or adjustments before bonding permanently. The drying time for rubber cement generally varies between 15 to 60 minutes.

Here are some factors that can influence the drying time:

1. Application thickness: Thicker layers of rubber cement will take longer to dry compared to thin, even layers.

2. Porous surface: If you are working on a porous surface, such as fabric or paper, the drying time may be longer because the rubber cement needs to penetrate and bond with the materials.

3. Temperature and humidity: Similar to contact cement, temperature and humidity also play a role in the drying time of rubber cement. Warmer temperatures and lower humidity levels can expedite the process.

It is important to keep in mind that these drying times are approximate and can vary based on environmental conditions and the specific brand of contact or rubber cement you are using.

To ensure the best results, always refer to the manufacturer’s instructions for the recommended drying time and application techniques for the particular adhesive you are working with.

Flexibility

Contact cement is renowned for its excellent flexibility, making it an ideal choice for a wide range of applications. Whether you’re working on arts and crafts projects or need to bond materials together for home repairs, contact cement offers the flexibility you need to ensure a durable and long-lasting bond.

One of the key advantages of contact cement is its ability to maintain its flexibility even under stress or movement. This makes it a popular choice for bonding materials that are subjected to regular movement, such as footwear or upholstery.

With contact cement, you can be confident that your creations will withstand the test of time, remaining flexible without compromising on strength.

Rubber cement, on the other hand, also offers impressive flexibility. This adhesive is commonly used in crafts and other applications where a temporary bond is desired.

The flexibility of rubber cement gives you the freedom to make adjustments or reposition your materials as needed before the adhesive fully sets.

While rubber cement is not as strong as contact cement, its flexibility makes it an excellent choice for projects that may require later modifications or repairs. The ability to remove and reapply materials bonded with rubber cement without causing damage adds to its flexibility.

| Flexibility | Contact Cement | Rubber Cement |

|---|---|---|

| Strength of Bond | Contact cement offers a strong and durable bond. | Rubber cement provides a temporary bond that can be easily removed. |

| Movement and Stress | Contact cement maintains its flexibility even under movement and stress. | Rubber cement remains flexible, allowing for adjustments and repositioning. |

| Longevity of Bond | Contact cement creates a long-lasting bond, ensuring durability over time. | Rubber cement may require occasional reapplication for optimal results. |

Removability

Rubber cement and contact cement are both used for various adhesive purposes, but their removability differs. Rubber cement is easily removable, making it a better choice for temporary applications, while contact cement provides a permanent bond, making it suitable for long-term projects.

Removing Contact Cement

Contact cement can be removed by using a solvent like acetone or mineral spirits. Wipe the affected area with a cloth soaked in the solvent. Scrub gently in a circular motion until the cement starts to loosen. Repeat the process until all the residue is gone. Clean the area with soap and water once the cement is fully removed.

Removing Rubber Cement

Rubber cement can be peeled off once it has dried completely. Carefully lift an edge of the rubber cement with your fingers or a blunt tool. Slowly peel back the cement, taking care not to damage the underlying surface. Any remaining residue can be rubbed off with an eraser or a damp cloth.

Best Uses

When choosing the right adhesive for your project, it’s important to understand the best uses of contact cement and rubber cement. Each type of adhesive has its own ideal applications, so knowing which one to use can make a significant difference in the success of your project.

Ideal Applications For Contact Cement

Contact cement is best suited for bonding large surface areas with no need for repositioning. It is commonly used for laminates, veneers, and large woodworking projects.

Due to its strong and permanent bond, contact cement is ideal for joining materials that are difficult to clamp or pressure together.

Ideal Applications For Rubber Cement

On the other hand, rubber cement is best for temporary bonding and easy repositioning. Its ideal applications include arts and crafts, mounting photos, and working with thin materials like paper or cardboard.

Rubber cement offers easy removal and minimal damage to surfaces, making it perfect for projects that require frequent adjustments.

Frequently Asked Questions For Contact Cement Vs Rubber Cement

Is Contact Cement Same As Rubber Cement?

Contact cement is not the same as rubber cement. Contact cement is stronger and bonds quicker, while rubber cement is more flexible and removable.

Is Dap Contact Cement The Same As Rubber Cement?

DAP contact cement is not the same as rubber cement. DAP is more heavy-duty for permanent bonding, while rubber cement is more temporary and flexible for lighter materials.

When Should I Use Rubber Cement?

You should use rubber cement for bonding non-porous surfaces, like leather or metal, and for temporary adhesive needs like collage or scrapbooking.

It provides a strong, flexible bond and is ideal for crafts and repairs. Avoid using on photos or paper, as it can cause damage.

Is Rubber Cement Strong?

Yes, rubber cement is strong. It provides a secure hold for various materials.

Conclusion

Both contact cement and rubber cement have their strengths and weaknesses. While contact cement is known for its strong and durable bond, rubber cement offers the advantage of repositionability.

Depending on your specific project and requirements, either option can be a reliable choice. Consider the factors discussed in this blog post to make an informed decision and achieve the best results for your adhesive needs.