Views: 69

Yes, you can screw into plexiglass, but it requires caution to prevent cracking or damage. Plexiglass is a versatile material that is commonly used in various applications due to its transparent and durable properties.

It is a type of acrylic material that can be drilled or screwed into, but care must be taken to avoid creating stress points that could lead to cracking.

Understanding the proper techniques and tools to use when screwing into plexiglass is essential to ensure a successful outcome without compromising the integrity of the material.

We will explore the considerations and steps involved in safely screwing into plexiglass for your DIY projects or professional installations.

Contents

What Is Plexiglass?

Plexiglass is a transparent plastic material commonly used in various applications. However, it is not recommended to screw directly into plexiglass as it may cause cracking and damage.

Plexiglass, also known as acrylic glass, is a lightweight and shatter-resistant alternative to traditional glass.

It is made from polymethyl methacrylate (PMMA) and is widely used in various applications due to its durability and versatility.

Composition Of Plexiglass

Plexiglass is composed of polymers derived from acrylic acid. The primary component, polymethyl methacrylate (PMMA), is a clear and transparent thermoplastic.

Other additives such as stabilizers, colorants, and UV absorbers may be incorporated to enhance specific properties of the plexiglass.

Properties Of Plexiglass

Plexiglass exhibits several notable properties that make it a favored material in numerous industries.

Some of the key properties of plexiglass include:

- Transparency: Plexiglass is highly transparent and allows for excellent light transmission, making it a popular choice for displays and signage.

- Durability: Despite its lightweight nature, plexiglass is remarkably durable and resistant to impact. It is around ten times stronger than traditional glass, making it less prone to breakage.

- Weather Resistance: Plexiglass has impressive weather resistance, retaining its optical properties even when exposed to harsh environmental conditions. It does not yellow or degrade as quickly as other materials.

- Chemical Resistance: Plexiglass demonstrates resistance to many chemicals, including solvents and acids, which contributes to its wide range of applications.

- Malleability: Plexiglass can be easily shaped and molded into various forms due to its malleability. This allows for the creation of intricate designs and customizations.

These properties make plexiglass an ideal choice for applications such as windows, aquariums, protective barriers, and more. Its versatility and aesthetic appeal have made it a popular material in both commercial and residential settings.

Mounting Options For Plexiglass

Making the right choice in mounting options for your plexiglass project is crucial for ensuring stability and a polished finish. Here are three popular methods to consider:

Adhesive Mounting

Using adhesive mounting is a simple and effective way to secure plexiglass without the need for drilling or screws. Opt for specialized plexiglass adhesive for a strong hold that won’t damage the material.

Screw Mounting

Screw mounting provides a secure and reliable option for attaching plexiglass. Pre-drill holes to prevent cracking and use carefully chosen screws that are suitable for plexiglass to avoid any damage.

Clamp Mounting

Clamp mounting is useful for temporary or adjustable installations. Choose clamps that are designed for use with plexiglass to ensure a secure fit without causing any harm to the material.

Can You Screw Into Plexiglass?

If you’re wondering if you can screw into plexiglass, the answer is yes, but it requires careful consideration and specific techniques to avoid cracks or damage.

Plexiglass, also known as acrylic, is a durable and versatile plastic material commonly used for various applications, including signage, protective barriers, and DIY projects.

Understanding the factors to consider and how to prevent cracks and damage when screwing into plexiglass is essential for successful installation.

Factors To Consider

Before attempting to screw into plexiglass, several factors need to be taken into account:

- Thickness of Plexiglass: Ensure that the plexiglass is thick enough to support the screw without compromising its structural integrity.

- Type of Screw: Select the appropriate screw type, such as self-tapping or thread-cutting, designed for use with plexiglass to reduce the risk of cracks.

- Drilling Technique: Pre-drill the holes with a sharp drill bit at a slow speed to create pilot holes before inserting the screws.

- Placement of Screws: Plan the placement of screws carefully, avoiding the edges of the plexiglass to minimize the risk of cracking.

Preventing Cracks And Damage

To prevent cracks and damage when screwing into plexiglass, consider the following precautions:

- Use a Proper Drill Bit: Utilize a drill bit specifically designed for use with plexiglass to minimize stress and prevent cracking during drilling.

- Apply Masking Tape: Place masking tape over the area to be drilled to reduce chipping and provide a guide for drilling precise holes.

- Control Screw Depth: Carefully control the depth to which the screws are inserted to avoid overtightening and exerting excessive pressure on the plexiglass.

- Use Lubrication: Apply a lubricant, such as soapy water or cutting oil, to the drill bit to reduce heat and friction during drilling, minimizing the risk of cracks.

Tips For Mounting And Anchoring Plexiglass

When it comes to mounting and anchoring plexiglass, there are several key considerations to keep in mind. From choosing the right screws to securing the plexiglass in place, these tips will help you successfully complete your project.

Choosing The Right Screws

Before you start mounting plexiglass, it’s crucial to select the appropriate screws for the job.

Opt for screws specifically designed for plastic materials, such as acrylic or plexiglass, to prevent cracking or chipping. Look for screws with a sharp, pointed tip and a wide, flat head to ensure a secure hold without damaging the material.

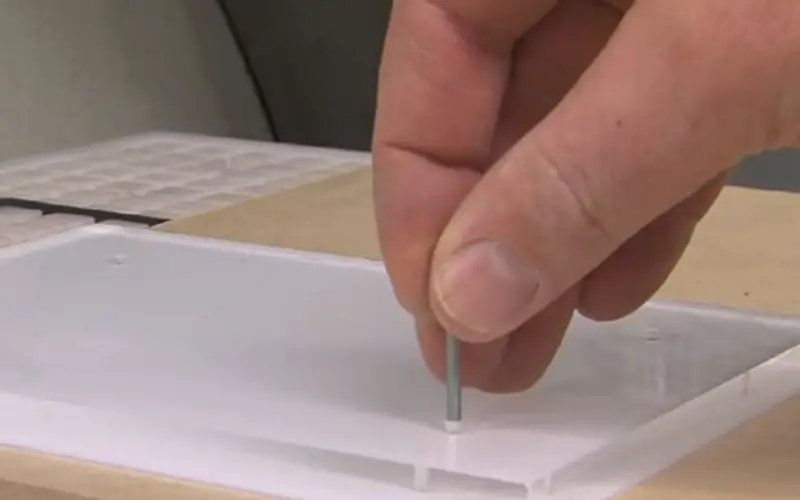

Drilling Holes In Plexiglass

When drilling into plexiglass, it’s important to take a cautious approach to avoid cracks or fractures. Use a sharp drill bit specifically designed for plastic and set your drill to a low speed to prevent overheating the material.

Additionally, securing the plexiglass with clamps or a supportive backing can minimize vibrations and reduce the risk of cracking during drilling.

Inserting Anchors

If your project requires additional support for mounting plexiglass, inserting anchors can provide a reliable solution.

Choose anchors suitable for plastic materials and ensure they are properly sized for the screws you plan to use. Carefully drill holes for the anchors, insert them securely, and follow the manufacturer’s instructions for optimal performance.

Securing The Plexiglass

Once the plexiglass is in place and the screws or anchors are inserted, ensure that the plexiglass is securely fastened without being overtightened.

Over-tightening can cause stress on the material and lead to cracks, so use a steady and gentle approach to achieve a secure fit. Regularly check the integrity of the mounting to ensure long-term stability.

Alternatives To Screwing Into Plexiglass

When it comes to working with plexiglass, screwing into it may not always be the best option.

Adhesive Options

Adhesives can provide a secure and clean way to attach items to plexiglass.

- Epoxy adhesives create strong bonds with plexiglass.

- Acrylic adhesives specifically designed for plexiglass offer excellent adhesion.

- Double-sided adhesive tapes are easy to use and leave no visible marks.

Clamping Methods

Clamping can also be an effective way to secure objects to plexiglass without damaging it.

- Spring clamps are simple to use and can hold items securely in place.

- C-clamps provide strong and adjustable pressure for a reliable hold.

- Vacuum clamps use suction to secure items without leaving any marks behind.

Frequently Asked Questions On Can You Screw Into Plexiglass

Can Plexiglass Be Screwed?

Yes, plexiglass can be screwed.

How Do You Drill Into Plexiglass Without Cracking It?

To drill into plexiglass without cracking, use a sharp drill bit, low drill speed, and light pressure.

Place masking tape over the area to prevent splintering. Start with a small pilot hole before drilling the final size.

Lubricate the drill bit with water to reduce heat buildup.

How Do You Make A Screw Hole In Plexiglass?

To make a screw hole in plexiglass, follow these steps:

1. Choose a drill bit specifically designed for plexiglass.

2. Mark the desired location for the hole.

3. Secure the plexiglass to a stable surface with clamps.

4. Start drilling at a slow speed to prevent cracking.

5. Continue drilling until the hole is complete.

Can You Screw Through Acrylic Sheets?

Yes, you can screw through acrylic sheets. It’s important to drill pilot holes first to prevent cracking.

Use screws with a larger diameter than the drill bit for a secure fit. Avoid overtightening to prevent damage to the acrylic.

Conclusion

Screwing into Plexiglass can be possible with proper tools and techniques. Remember to drill slowly for best results. Take precautions to avoid cracking or damaging the material.

With patience and care, you can successfully secure items to Plexiglass surfaces. Experiment and practice for optimal outcomes.