Yes, PEX can be used for air lines. It is a flexible and durable material suitable for various applications.

PEX tubing is commonly used for plumbing and heating systems due to its resistance to corrosion and chemicals. When it comes to air lines, PEX offers advantages such as easy installation, cost-effectiveness, and flexibility.

PEX tubing is lightweight and can be easily bent and shaped to fit different configurations, making it a popular choice for air line installations.

Additionally, PEX is resistant to temperature changes and will not corrode over time, ensuring a long-lasting air line system. PEX tubing is a versatile option for air lines, providing reliability and efficiency.

Contents

Benefits Of Using Pex For Air Lines

The use of Pex for air lines offers several benefits that make it a popular choice in various applications. Its unique properties provide durability, flexibility, and corrosion resistance, making it a reliable option for air lines.

Durability

Pex is known for its exceptional durability, making it suitable for demanding air line applications. Its robust construction ensures that it can withstand high pressure and temperature fluctuations without compromising performance.

This durability minimizes the risk of leaks and ensures that the air lines remain functional for extended periods.

Flexibility

Flexibility is another key benefit of using Pex for air lines. Its pliable nature allows for easy installation, even in challenging or confined spaces. Pex can be bent to navigate around obstacles without the need for additional fittings or connectors.

This flexibility also simplifies maintenance and repairs, as sections of Pex can be easily replaced without disrupting the entire air line system.

Corrosion Resistance

Pex exhibits excellent corrosion resistance, making it ideal for air lines. Unlike metal materials, Pex does not corrode or develop rust over time.

This resistance to corrosion ensures that the air being delivered remains contaminant-free and maintains its quality.

Additionally, it enhances the longevity of the air line system, reducing the need for frequent replacements or repairs.

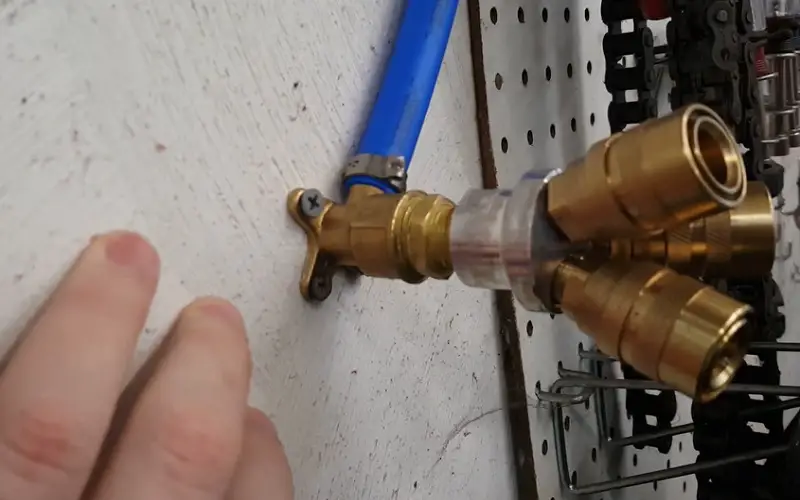

Installation Process Of Pex For Air Lines

Pex can be utilized for air lines through a straightforward installation process, ensuring durability and efficiency.

It offers a cost-effective solution for air distribution systems, suitable for various applications requiring compressed air. The flexibility and ease of installation make Pex a viable option for air line installations.

Preparation

Before starting the installation, make sure the work area is clean.

Tools Required

Gather the necessary tools: Pex tubing, cutting tool, crimping tool.

Cutting And Joining Pex

Measure Pex tubing accurately, then use a cutting tool to make precise cuts.

Securing Pex

Ensure Pex is properly secured using clamps or clips as needed.

Considerations Before Using Pex For Air Lines

Pex can be used for air lines, but there are important considerations to keep in mind. Ensure proper sizing, use appropriate fittings, and understand the limitations of Pex when it comes to pressure and temperature.

Expert installation is crucial for optimal performance and safety. Considerations Before Using Pex for Air Lines Pex, also known as cross-linked polyethylene, is commonly used in plumbing due to its flexibility and durability.

However, before considering using Pex for air lines, it’s crucial to understand the limitations and factors that should be taken into account for safe and effective operation.

Operating Pressure

Pex tubing has a maximum operating pressure rating that varies depending on factors such as tubing size and wall thickness.

It is essential to ensure that the operating pressure of the air compressor and the pneumatic tools does not exceed the recommended pressure limit for the specific Pex tubing being utilized.

Temperature Range

Pex tubing is designed to withstand a specific temperature range. Extreme temperatures can affect the flexibility and strength of the tubing, potentially leading to cracks or leaks.

It is crucial to verify that the operating temperature of the air system falls within the recommended range for the Pex tubing.

Air Quality

The quality of the air circulating through the Pex air lines is a significant consideration.

Contaminants such as oil, moisture, and debris can have adverse effects on Pex tubing, leading to degradation and potential failure. Proper filtration and maintenance of the air supply are vital to ensure the longevity of the Pex air lines.

Comparing Pex With Other Materials For Air Lines

When it comes to air lines, choosing the right material is crucial for the safety and efficiency of your system. Pex, known for its flexibility and durability, has been gaining popularity as an alternative to traditional materials.

In this section, we’ll compare Pex with other materials commonly used for air lines, including copper, galvanized steel, and polyethylene.

Copper

Copper has long been the go-to material for air lines due to its excellent corrosion resistance and high thermal conductivity. However, copper is relatively expensive and requires skilled labor for installation.

Galvanized Steel

Galvanized steel is a robust choice for air lines, offering high durability and strength. However, it is susceptible to corrosion over time, especially in humid or corrosive environments, which can lead to air leaks and system inefficiencies.

Polyethylene

Polyethylene, like Pex, is a versatile and cost-effective option for air lines. Polyethylene is lightweight, easy to install, and resistant to corrosion. However, it is not as flexible as Pex and may require additional fittings for complex installations.

Frequently Asked Questions For Can Pex Be Used For Air Lines

Is Pex Legal For Air Lines?

Yes, PEX is legal for air lines. PEX, or cross-linked polyethylene, tubing is commonly used in plumbing, but it can also be used in air line systems.

It is a durable material that can withstand high temperatures and pressure, making it suitable for air line applications.

What Pipe To Use For Air Lines?

For air lines, it is best to use pipes made of durable materials like steel, copper, or aluminum.

These materials offer excellent strength and resistance to corrosion, ensuring reliable and long-lasting performance for your air line system.

How Much Air Pressure Can Pex Handle?

PEX can typically handle air pressure up to 100 PSI, making it suitable for various applications.

Can Pex Be Used For Hvac?

Yes, PEX can be used for HVAC systems due to its flexibility and durability. It is commonly used for hydronic heating systems and radiant floor heating.

PEX tubing can effectively handle the demands of HVAC applications, providing efficient and reliable performance.

Conclusion

In essence, Pex can be effectively used for air lines due to its versatility and durability. When considering options for your air line systems, keep in mind the benefits of using Pex piping.

Its flexibility and cost-effectiveness make it a reliable choice for air line installations. Explore the possibilities of incorporating Pex into your air line system to enhance performance and efficiency.