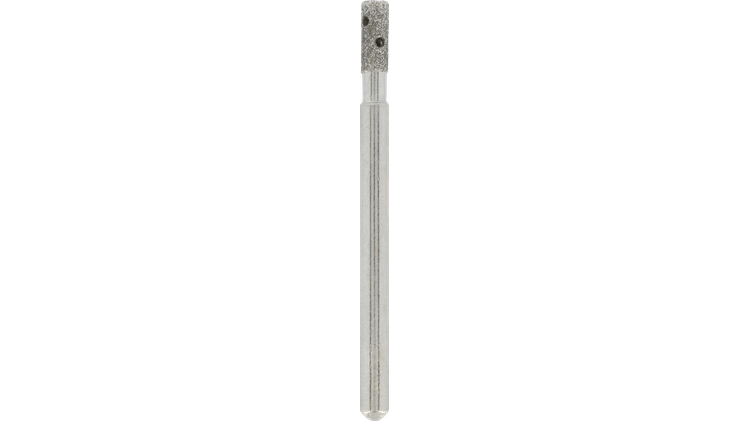

A diamond-coated Dremel bit is ideal for cutting glass efficiently and precisely. It ensures clean cuts.

Glass cutting can be a delicate and challenging task, requiring the right tools for a successful outcome. When it comes to using a Dremel tool to cut glass, selecting the correct bit is crucial.

Among the various options available, a diamond-coated Dremel bit stands out for its ability to cut through glass effectively. By understanding the importance of choosing the right tool for the job, you can achieve precise and clean cuts on glass surfaces.

We will explore the benefits of using a diamond-coated Dremel bit for cutting glass and provide tips for achieving optimal results.

Contents

- Selecting The Right Dremel Bit For Glass Cutting

- Understanding Diamond Drill Bits

- Safety First: Preparing To Cut Glass

- Step-by-step Guide To Cutting Glass With A Dremel

- Troubleshooting Common Issues

- Enhancing Precision: Accessories And Attachments

- Creative Projects For Glass Cutting Enthusiasts

- Maintaining Your Dremel And Bits For Longevity

- Advanced Techniques For Experienced Crafters

- Exploring The Community: Resources And Inspiration

- Frequently Asked Questions

- Conclusion

Selecting The Right Dremel Bit For Glass Cutting

Discover the ideal Dremel bit for cutting glass effortlessly. Opt for a diamond-encrusted rotary tool bit for precise glass cutting results. Create intricate glass designs with the right Dremel bit.

Material Compatibility

Glass cutting with a Dremel rotary tool requires the use of specific bits that are compatible with the material. Not all Dremel bits are created equal, and some may not be suitable for cutting glass.

It’s essential to choose the right bit for the job to ensure a clean and precise cut. Diamond-coated bits are the most suitable for cutting glass, while tungsten carbide and silicon carbide bits are not recommended.

Bit Shapes And Their Uses

Dremel bits come in various shapes and sizes, each with its specific use and application. The most commonly used bits for glass cutting are the cylinder, ball, and cone-shaped bits. Cylinder-shaped bits are ideal for straight cuts, while ball and cone-shaped bits are best for curved cuts and shaping.

The diamond-coated bits come in various grit sizes, with finer grits suitable for polishing and finishing work. When selecting a Dremel bit for glass cutting, it’s essential to consider the shape of the material you wish to cut.

Curved surfaces require a bit that can move with the contour of the glass, while flat surfaces require a flat-bottomed bit. Selecting the right Dremel bit for glass cutting is critical to achieving clean and precise cuts.

It’s essential to consider the material compatibility and the shape of the glass when choosing a bit. With the right bit and technique, you can transform ordinary glass into a beautiful work of art.

Understanding Diamond Drill Bits

Diamond drill bits are crucial for cutting glass with a Dremel tool effectively. These specialized bits have a diamond-coated tip that ensures precise and clean cuts on glass surfaces. Mastering the technique of using a diamond drill bit can elevate your glass crafting projects to the next level.

Understanding Diamond Drill Bits When it comes to cutting glass, diamond drill bits are the go-to choice for achieving precision and clean cuts. These specialized tools are designed to handle the hardness of glass, making them essential for various glasswork projects.

Advantages For Glass Work

Diamond drill bits offer several advantages for working with glass. Their precision and clean cutting capabilities make them ideal for creating intricate designs and patterns.

These bits are also effective for drilling holes in glass, allowing for the insertion of hardware or creating decorative accents.

Maintenance And Care

Proper maintenance and care are crucial for ensuring the longevity and performance of diamond drill bits. After use, it’s important to clean the bits thoroughly to remove any glass residue and prevent clogging.

Additionally, storing the bits in a secure and organized manner can help prevent damage and maintain their sharpness.

In conclusion, understanding the advantages of diamond drill bits for glass work and implementing proper maintenance and care practices is essential for achieving optimal results and extending the lifespan of these specialized tools.

Safety First: Preparing To Cut Glass

Prepare for glass cutting by prioritizing safety. Use a diamond-encrusted Dremel bit to cut glass with precision and care. Always wear protective gear and work in a well-ventilated area to minimize the risk of injury.

Protective Gear Essentials

Before cutting glass with a Dremel bit, ensure you have the necessary protective gear to prevent accidents.

Setting Up Your Workspace

Prepare a safe and organized workspace with a stable surface for cutting glass with your Dremel bit.

Protective Gear Essentials

Wear safety goggles and protective gloves to shield your eyes and hands from glass shards.

Setting Up Your Workspace

Clear your workspace of clutter and distractions to focus on cutting glass precisely and safely.

Step-by-step Guide To Cutting Glass With A Dremel

Are you looking to cut glass with precision and ease? A Dremel rotary tool is the perfect solution. With the right bit and technique, you can achieve clean, smooth cuts in glass, perfect for a variety of DIY projects.

This step-by-step guide will walk you through the process, from securing the glass to the finishing touches, so you can confidently cut glass with a Dremel.

Securing The Glass

Before you begin, it’s crucial to secure the glass to prevent any slippage or movement during the cutting process. Here’s a simple method to ensure the glass stays in place:

- Place the glass on a flat, stable surface.

- Use clamps to secure the glass in position, ensuring it doesn’t shift while cutting.

Starting Your Cut

Now that the glass is secure, it’s time to begin the cutting process. Follow these steps to initiate the cut:

- Attach a diamond wheel bit to your Dremel tool – the ideal choice for cutting through glass.

- Put on safety goggles and a dust mask to protect yourself from glass shards and debris.

- Start the Dremel at a low speed and gradually increase as you begin to score the glass.

Finishing Touches

Once you’ve completed the cut, it’s essential to refine the edges for a clean, professional finish. Here’s how to perfect your glass cut:

- Switch to a sanding bit to smooth and polish the edges of the glass.

- Gently run the Dremel along the cut edge to remove any roughness or sharp points.

Troubleshooting Common Issues

When working with a Dremel tool to cut glass, you may encounter common issues that can affect the quality of your work.

Troubleshooting these issues is essential to ensure smooth and precise glass cutting. Below are some tips for dealing with common problems when using a Dremel bit to cut glass.

Dealing With Cracks And Chips

If you notice cracks or chips forming as you cut the glass, it may be due to excessive pressure or inadequate lubrication.

Reduce the pressure applied to the glass and ensure that the cutting area is well lubricated with water or a glass cutting oil. This will help minimize the risk of cracks and chips, resulting in a cleaner cut.

Overcoming Dremel Bit Slippage

Dremel bit slippage can occur when the bit is not securely tightened or when excessive force is applied during the cutting process.

Ensure that the Dremel bit is securely tightened in place before starting the cutting process. Additionally, try to maintain a consistent and controlled cutting motion to prevent the bit from slipping on the glass surface.

Enhancing Precision: Accessories And Attachments

Discover the ideal Dremel bit for cutting glass, enhancing precision with the right accessories and attachments. Achieve clean and accurate cuts effortlessly for your glass projects.

Using A Dremel Rotary Tool Workstation

Helpful Guides And Stencils

Enhancing Precision: Accessories and Attachments Glass cutting with a Dremel bit requires precision and the right tools. Enhance your cutting accuracy with accessories and attachments.

Using A Dremel Rotary Tool Workstation

- A workstation provides stability for intricate glass cutting projects.

- Secure the glass in place for controlled cutting motions.

- Minimize vibrations that can affect cutting accuracy.

Helpful Guides And Stencils

- Guides ensure straight and precise cuts on glass surfaces.

- Stencils help create intricate designs with ease.

- Enhance your creativity and precision with these tools.

Creative Projects For Glass Cutting Enthusiasts

Glass cutting enthusiasts can explore a world of creative projects using Dremel bits to cut glass. From home decor to personalized gifts, there are numerous possibilities for those who enjoy working with glass.

Whether you are a hobbyist or a professional, Dremel tools offer precision and versatility, making them perfect for a wide range of glass cutting projects.

Home Decor Ideas

Enhance your living space with stunning glass accents using Dremel bits. Create striking glass mosaic wall art or design elegant glass candle holders.

Transform ordinary glass vases into unique centerpieces by adding intricate designs or etching patterns. The possibilities are endless, and Dremel tools make it easy to bring your creative vision to life.

Personalized Glass Gifts

Impress your loved ones with personalized glass gifts crafted using Dremel tools. Engrave names, dates, or special messages on glassware to create memorable keepsakes.

Craft custom-designed glass ornaments or jewelry for a truly unique and heartfelt gift. With Dremel bits, you can add a personal touch to any glass item, making it a cherished and one-of-a-kind present.

Maintaining Your Dremel And Bits For Longevity

Using a Dremel to cut glass is a skill that requires patience and precision. However, maintaining your Dremel and bits is just as important as using them correctly.

By following some simple cleaning and replacement guidelines, you can ensure your Dremel and bits last for a long time.

Cleaning Best Practices

- Always unplug your Dremel before cleaning it.

- Use a soft, dry cloth to clean the body of the Dremel.

- For bits, use a small, soft-bristled brush to remove any debris or residue.

- For tough residue, use a small amount of rubbing alcohol on a cloth to wipe the bit clean.

- Never use water to clean your Dremel or bits, as it can damage the internal components.

When To Replace Your Bits?

It’s important to replace your Dremel bits when they become dull or damaged. Here are some signs that it’s time to replace your bits:

- The bit is no longer cutting through glass with ease and is taking longer to make cuts.

- The bit is chipped or cracked.

- The bit is starting to show signs of wear, such as a dull finish or discoloration.

Replacing your bits regularly will ensure that you are getting the best possible results and will prevent damage to your Dremel.

Advanced Techniques For Experienced Crafters

Experienced crafters can elevate their glass cutting skills with advanced techniques and tools. Discover how to create intricate designs and patterns and combine glass cutting with other materials for unique creations.

Intricate Designs And Patterns

Use diamond-coated bits for intricate designs and precise detailing on glass surfaces. Experiment with different shapes and sizes to achieve varying effects.

Combining Glass Cutting With Other Materials

Explore the possibilities of incorporating glass with metal or wood in your projects. Create stunning mixed-media pieces by blending textures and colors.

Exploring The Community: Resources And Inspiration

Online Forums And Groups

Joining online forums and groups can provide a wealth of knowledge and inspiration when it comes to using Dremel bits to cut glass.

Communities like Glass Art Society, The Guild of Glass Engravers, and The Dremel Enthusiasts Group on Facebook offer a platform to connect with fellow glass enthusiasts, exchange tips, and seek advice on the best Dremel bits for specific glass cutting projects.

Workshops And Classes

Attending workshops and classes conducted by glass artists and professionals is a fantastic way to gain hands-on experience and learn about the latest techniques and tools for cutting glass with Dremel bits.

Many art centers, craft schools, and even local community colleges offer workshops and classes dedicated to glass cutting, where you can interact with experts and fellow hobbyists to expand your skills and creativity.

Frequently Asked Questions

What Bit Do I Use In My Dremel To Cut Glass?

To cut glass with a Dremel, use a diamond wheel bit. It’s important to wear safety gear, mark the glass where you want to cut it, and go slow and steady. Be careful not to apply too much pressure or the glass may crack.

What Dremel Bit Drills Through Glass?

A diamond drill bit is the best for drilling through glass with a Dremel tool. Its hard, abrasive surface makes it efficient and precise.

What Kind Of Bit Cuts Glass?

A diamond bit cuts glass effectively due to its hardness and precision. It creates clean and precise cuts.

Can A Dremel Be Used On Glass?

Yes, a Dremel can be used on glass to cut, carve, and etch designs. It’s important to use the correct attachment and technique for best results.

Conclusion

Finding the right Dremel bit for cutting glass is crucial for achieving precise and clean results. By understanding the different types of bits available and their specific uses, you can tackle glass cutting projects with confidence. Remember to prioritize safety and take your time to ensure accurate and professional-looking outcomes.