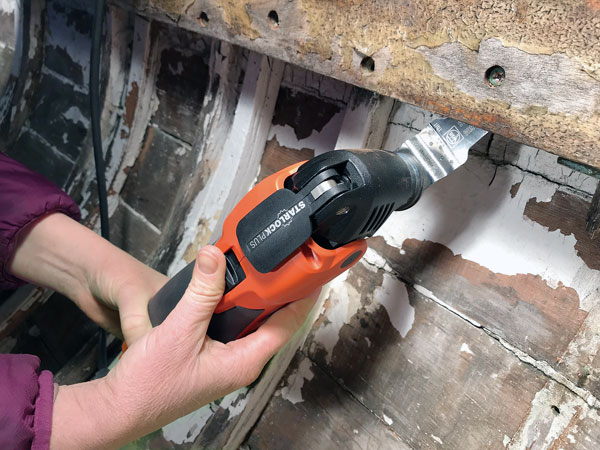

Yes, an oscillating multi tool can be used to cut tile effectively. An oscillating multi tool is a versatile and handy power tool that is capable of performing various tasks, including cutting tile.

With its rapid back-and-forth oscillating motion, this tool can make precise cuts in different materials, including ceramic and porcelain tiles.

Whether you need to make straight cuts, notches, or even intricate designs, an oscillating multi tool equipped with a diamond-edged blade can get the job done with precision and efficiency.

This makes it a convenient tool for DIY enthusiasts, homeowners, and professionals in the construction and remodeling industries.

We will explore the benefits and limitations of using an oscillating multi tool for tile cutting and provide you with useful tips to achieve the best results. So, let’s dive in!

Contents

- Pros And Cons Of Using An Oscillating Multi Tool For Tile Cutting

- Types Of Blades For Tile Cutting

- Step-by-step Guide For Cutting Tile With An Oscillating Multi Tool

- Tips And Tricks For Precision Cutting

- Safety Precautions

- Frequently Asked Questions Of Can You Cut Tile With Oscillating Multi Tool

- Conclusion

Pros And Cons Of Using An Oscillating Multi Tool For Tile Cutting

When it comes to tile cutting, using an oscillating multi tool can be a game-changer. Let’s explore the pros and cons of employing this versatile tool for your tile cutting needs.

Advantages Of Using An Oscillating Multi Tool

- Versatility: Can cut various tile materials efficiently.

- Precision: Allows for detailed and accurate cuts.

- Ease of Use: Simple operation even for beginners.

- Compact Design: Maneuverability in tight spaces.

Limitations Of Using An Oscillating Multi Tool

- Speed: Slower cutting compared to some tile saws.

- Noise: Can be louder than traditional cutting methods.

- Dust: Produces more dust, requiring proper ventilation.

- Blade Wear: Blades may wear out quicker with heavy use.

Types Of Blades For Tile Cutting

When it comes to tile cutting, using the right blade is crucial for achieving neat and precise cuts. Different types of blades are designed for various tasks, including tile cutting, grout removal, and more.

Let’s delve into the various types of blades commonly used for tile cutting, each serving a unique purpose.

Diamond Blades

Diamond blades are ideal for cutting through hard materials like ceramic, porcelain, and stone tiles.

These blades feature industrial-grade diamonds embedded into the edge, offering durability and precision. The diamond particles effortlessly grind through tough tile surfaces, producing clean and smooth cuts with minimal chipping.

Carbide-tipped Blades

Carbide-tipped blades are suitable for cutting softer tiles such as quarry, slate, and limestone.

The carbide tips provide excellent cutting performance and are more budget-friendly compared to diamond blades. These blades work efficiently to produce accurate cuts, making them a versatile choice for various tiling projects.

Grout Removal Blades

Grout removal blades are designed specifically for removing grout between tiles. These blades feature a specialized design with a narrow profile, allowing them to access tight spaces.

Whether it’s repairing grout lines or removing old grout for renovation, these blades are essential for maintaining the quality and appearance of tiled surfaces.

Step-by-step Guide For Cutting Tile With An Oscillating Multi Tool

Learn how to effectively cut tile using an oscillating multi-tool with our detailed step-by-step guide. Discover the versatility of this tool for precision cuts in tile installation projects. Master the technique and achieve professional results with ease.

Cutting tile with an oscillating multi-tool can be a precise and efficient process when done correctly. Follow these steps for perfect tile cutting results.

Marking The Cut Line

Use a pencil and ruler to mark the cut line on the tile surface.

Selecting The Right Blade

- Choose a diamond-grit or carbide-grit blade for cutting tiles.

- Make sure the blade is suitable for tile material being cut.

Securing The Tile

- Place the tile on a secure surface and clamp it down to prevent movement.

- Ensure the area around the tile is clear for safe cutting.

Making The Cut

Turn on the oscillating tool and gently guide the blade along the marked cut line.

Finishing And Cleaning

- Smooth the cut edges of the tile with sandpaper to remove any rough edges.

- Clean the tile and the work area to remove any dust or debris.

Tips And Tricks For Precision Cutting

When it comes to cutting tiles, the oscillating multi-tool has proven to be a versatile and effective tool. It allows for precise cuts without the risk of damaging the surrounding tiles.

However, to achieve precise cutting, there are a few tips and tricks that can make a significant difference in the result.

In this article, we will explore three essential aspects to consider when using an oscillating multi-tool for precision cutting: maintaining consistent pressure, using guide attachments, and controlling speed and oscillation.

Maintaining Consistent Pressure

One crucial factor in achieving precision cutting with an oscillating multi-tool is to maintain consistent pressure throughout the entire cutting process. Applying too much or too little pressure can lead to uneven cuts and potential damage to the tile.

It is essential to apply firm but controlled pressure to ensure a clean and accurate cut. Additionally, keeping a steady hand and using the tool’s weight to your advantage can also contribute to maintaining consistent pressure.

Using Guide Attachments

Guide attachments are invaluable when it comes to achieving precision cuts with an oscillating multi-tool.

These attachments act as a guide, providing a stable and straight cutting path. They help prevent the tool from veering off course, ensuring that your cuts are accurate and aligned with your desired measurements.

Guide attachments are available in various sizes, allowing for versatility in different cutting tasks. By using guide attachments, you can have better control over the tool, resulting in cleaner and more precise cuts.

Controlling Speed And Oscillation

The speed and oscillation settings on an oscillating multi-tool play a crucial role in achieving precision cuts. Controlling the speed allows you to adapt to different tile materials and thicknesses, ensuring optimal cutting performance.

Lower speeds are generally recommended for more delicate materials, while higher speeds can be effective for tougher tiles.

Additionally, adjusting the oscillation angle can help you achieve smoother and more precise cuts. It’s essential to experiment with different speed and oscillation settings to find the perfect combination for each cutting task.

Safety Precautions

When it comes to cutting tile with an oscillating multi-tool, safety should be your top priority. By taking proper precautions, you can ensure a safe and accident-free experience. Here are some important safety measures to keep in mind:

Wearing Protective Gear

Before you start cutting tile with an oscillating multi-tool, it is crucial to wear the right protective gear to safeguard yourself against potential injuries.

The following gear is recommended:

- Safety goggles or glasses to protect your eyes from flying debris

- A dust mask or respirator to prevent inhalation of dust particles

- Heavy-duty gloves to protect your hands from cuts or burns

By wearing the appropriate protective gear, you minimize the risk of accidents and ensure your safety throughout the cutting process.

Using Clamps And Supports

When using an oscillating multi-tool to cut tile, it is essential to secure the tile firmly in place. This can be achieved by using clamps or supports to prevent any movement.

By doing so, you not only improve the accuracy of your cuts but also reduce the chances of the tile shifting unexpectedly.

Consider using a sturdy workbench or a tile saw stand to provide additional stability. This will help you maintain control over the tool and minimize the risk of accidents.

Avoiding Contact With Moving Parts

One of the most critical safety precautions to follow is to avoid any contact with the moving parts of the oscillating multi-tool. The tool’s blades or attachments can spin at high speeds, posing a serious risk if mishandled.

Make sure to keep your fingers, clothing, and other body parts away from the blade while the tool is in operation. Always use the provided handles and grips to maintain a safe distance from the cutting area.

When changing blades or attachments, ensure that the tool is disconnected from the power source to eliminate the possibility of accidental activation.

| Important Safety Tips: |

|---|

| 1. Wearing protective gear: Safety goggles, dust mask, and gloves are essential for your protection. |

| 2. Using clamps and supports: Secure the tile firmly in place to minimize movement. |

| 3. Avoiding contact with moving parts: Keep your fingers and body parts away from the blade during operation and when changing blades. |

Following these safety precautions will not only protect you from potential harm but also ensure a smooth and successful tile cutting experience.

Frequently Asked Questions Of Can You Cut Tile With Oscillating Multi Tool

Will A Diamond Grit Oscillating Blade Cut Tile?

Yes, a diamond grit oscillating blade can cut tile effectively and efficiently. It is designed to provide precise and clean cuts, making it a popular choice for tile cutting projects.

Can You Cut Straight With An Oscillating Tool?

Yes, you can cut straight with an oscillating tool. It is versatile for precise cuts.

Can You Cut Tile With A Dremel Multi Max?

Yes, a Dremel Multi-Max with the appropriate blade can be used to cut tile efficiently.

Can Ryobi Multi Tool Cut Tile?

Yes, the Ryobi multi tool is capable of cutting tile. It is a versatile tool that cuts through various materials, including ceramic and porcelain tiles, with precision and ease. With its sharp blade and powerful motor, it allows for accurate and efficient tile cutting.

Conclusion

Using an oscillating multi-tool to cut tiles is efficient and precise. With the right blade and technique, you can achieve clean cuts effortlessly.

Remember to prioritize safety and practice on scrap tiles before tackling your project. Embrace the versatility of the oscillating multi-tool for your tile cutting needs.